Yes, Teflon washers are specifically designed to be used without any external lubricant. Their inherent material properties create a "self-lubricating" surface, which is one of their primary advantages. This makes them exceptionally reliable in applications where adding oil or grease is impractical or undesirable.

While Teflon washers function perfectly well without lubricant due to their low-friction nature, adding a light lubricant can enhance the smoothness of the action. The decision depends entirely on whether you prioritize minimal maintenance or maximum operational fluidity.

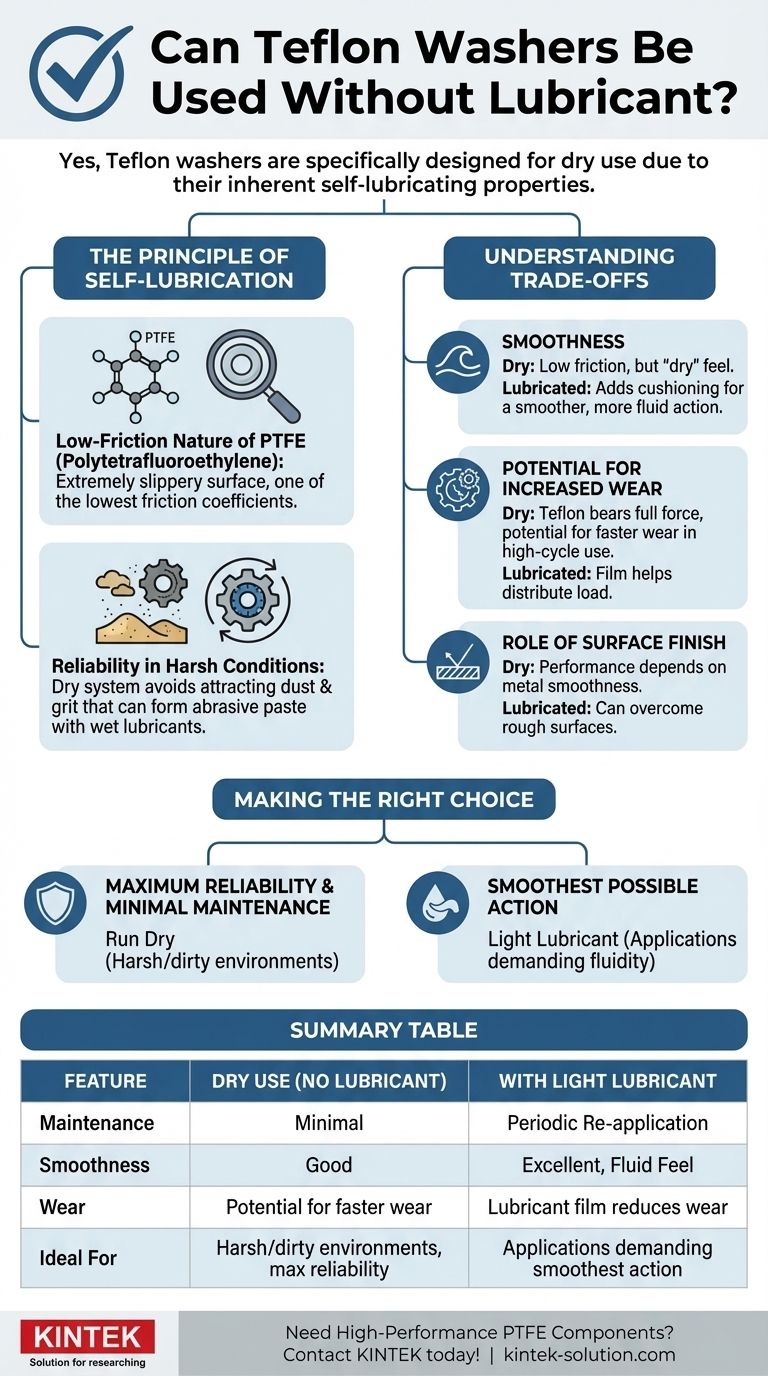

The Principle of Self-Lubrication

To understand why Teflon works without lubricant, we need to look at the material itself. The unique properties of Teflon are what make it a premier choice for low-friction applications.

The Low-Friction Nature of PTFE

Teflon is the brand name for a material called Polytetrafluoroethylene (PTFE). This polymer has one of the lowest coefficients of friction of any known solid material.

Its molecular structure creates an incredibly "slippery" surface. This means that even when pressed against a metal surface, it allows for smooth movement with very little resistance, effectively lubricating itself.

Reliability in Harsh Conditions

This self-lubricating quality is a significant advantage in field use. Traditional wet lubricants, like oil or grease, can attract and hold onto dust, sand, and other debris.

This mixture of lubricant and grit can form an abrasive paste, which can actually accelerate wear and hinder the mechanism's function. A dry Teflon system avoids this problem entirely, ensuring more consistent performance when exposed to the elements.

Understanding the Trade-offs of Running Dry

While Teflon washers do not require lubrication, choosing to run them dry involves a set of performance trade-offs that you should understand.

The Impact on Smoothness

A completely dry Teflon washer provides low friction, but it may not provide the most fluid-feeling action. Some users notice a certain "dry" or "non-hydraulic" feel.

Adding a very thin film of a light lubricant can fill in the microscopic imperfections on the surfaces of the washer and the metal. This creates a cushioning effect that can make the action feel smoother and more refined, even if the raw friction is not significantly lower.

Potential for Increased Wear

Teflon is a relatively soft material. In a high-pressure, high-cycle mechanism, a lubricant film can help distribute load and reduce direct, concentrated contact between the metal and the washer.

Running the system completely dry means the Teflon bears the full force of the friction. Over a very long period of heavy use, this could potentially lead to slightly faster wear compared to a properly lubricated system.

The Role of Surface Finish

The performance of a dry Teflon washer is also dependent on the finish of the metal surfaces it contacts. A smoother, more polished metal surface will result in a smoother action.

If the metal surfaces are rough, running the washers dry may feel gritty or cause the action to catch. In this case, a lubricant can help overcome the friction caused by the poor surface finish.

Making the Right Choice for Your Goal

Your ideal setup depends entirely on how you value ease of maintenance versus the subjective feel of the mechanism's performance.

- If your primary focus is maximum reliability and minimal maintenance: Run the Teflon washers completely dry, as this prevents the attraction of performance-degrading dust and grit.

- If your primary focus is the smoothest possible action: Apply a very light film of a quality, non-migrating lubricant to enhance the feeling of fluidity.

Ultimately, Teflon's versatility gives you the power to tune the system to best suit your specific needs.

Summary Table:

| Feature | Dry Use (No Lubricant) | With Light Lubricant |

|---|---|---|

| Maintenance | Minimal (no grit attraction) | Requires periodic re-application |

| Smoothness | Good, low friction | Excellent, fluid feel |

| Wear in High-Cycle Use | Potential for slightly faster wear | Lubricant film can reduce wear |

| Ideal For | Harsh/dirty environments, max reliability | Applications demanding the smoothest action |

Need High-Performance PTFE Components for Your Application?

Whether your priority is maximum reliability with self-lubricating Teflon washers or a custom solution for a specific feel, KINTEK has the expertise. We manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders to meet your exact requirements.

Contact KINTEL today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability