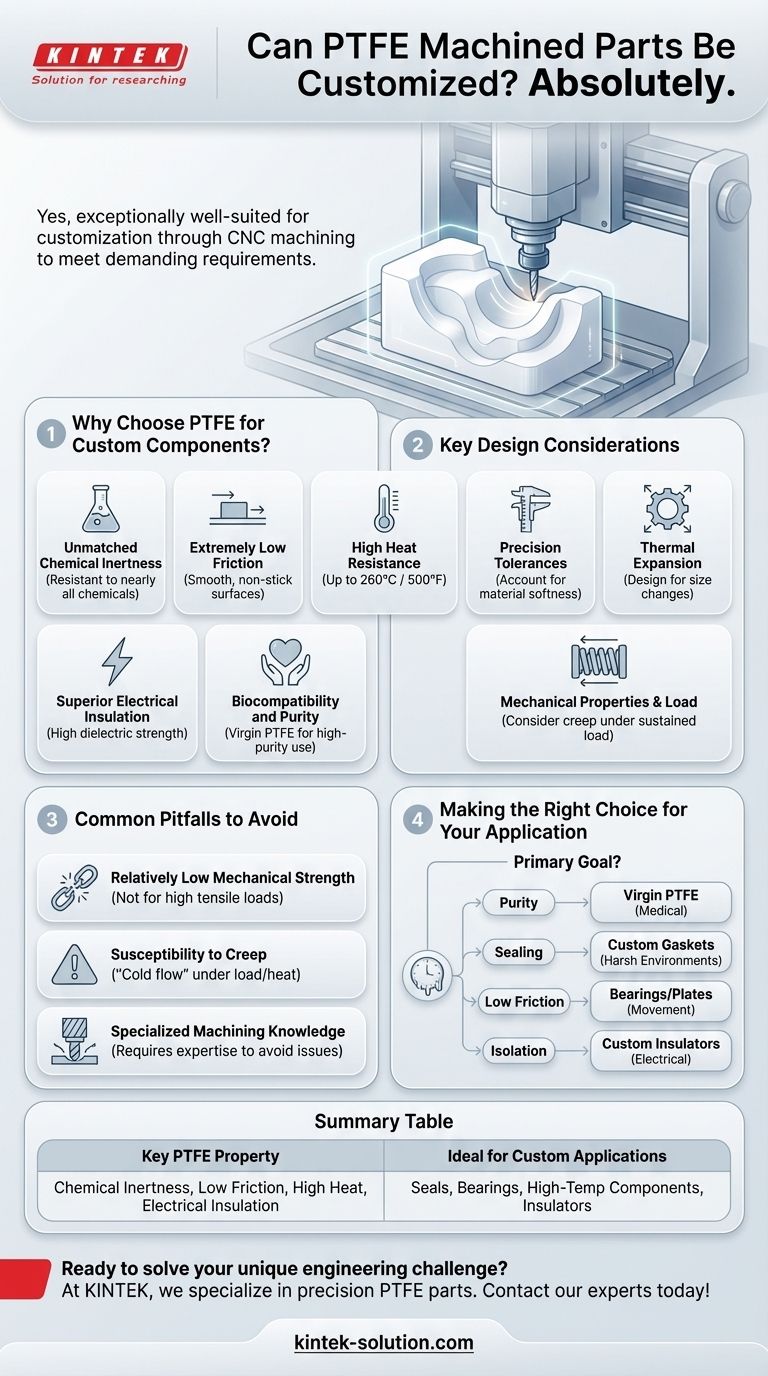

Yes, absolutely. Polytetrafluoroethylene (PTFE) is not only customizable but is exceptionally well-suited for it. Its unique properties and excellent machinability allow for the creation of highly specialized parts through processes like CNC machining, tailored precisely to meet demanding operational requirements.

The core consideration is not if PTFE can be customized, but how to design that customization to leverage its distinct advantages—like chemical inertness and low friction—while accounting for its material properties, such as thermal expansion and compressive strength.

Why Choose PTFE for Custom Components?

The decision to machine custom parts from PTFE is almost always driven by its unique combination of high-performance characteristics. Standard off-the-shelf components often cannot meet the specific challenges that PTFE is designed to solve.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This makes it an ideal material for custom seals, gaskets, and tank linings used in chemical processing, pharmaceutical, and food and beverage industries.

Extremely Low Friction

With one of the lowest coefficients of friction of any solid material, PTFE is perfect for applications requiring smooth, non-stick surfaces. Custom bearings, slide plates, and seals are common examples where this property is essential.

High Heat Resistance

PTFE components can operate continuously at temperatures up to 260°C (500°F). This allows for the design of custom parts that maintain their integrity in high-temperature environments where other polymers would fail.

Superior Electrical Insulation

As an excellent electrical insulator with high dielectric strength, PTFE is frequently machined into custom insulators, connectors, and components for demanding electrical and electronic applications.

Biocompatibility and Purity

Virgin PTFE, which contains no additives or fillers, is exceptionally pure and biocompatible. This makes it a preferred choice for custom surgical instruments, prosthetic devices, and equipment used in high-purity manufacturing.

Key Design Considerations for Customization

Successful customization requires a clear understanding of PTFE's material behavior. Simply creating a shape is not enough; the design must account for how the material will perform in its intended environment.

Precision Tolerances

Modern CNC machining can produce PTFE parts with very tight tolerances. However, the design must account for the material's softness and potential for deformation during the machining process itself.

Thermal Expansion

PTFE has a relatively high rate of thermal expansion. Custom parts must be designed with sufficient clearance to accommodate changes in size due to temperature fluctuations in the operating environment.

Mechanical Properties and Load

The design must consider the compressive strength and potential for "creep" (slow deformation under sustained load). While strong, PTFE is not intended for high-load structural applications without reinforcement or proper design considerations.

Common Pitfalls to Avoid

Understanding the limitations of PTFE is as important as knowing its strengths. These trade-offs are critical for successful component design.

Relatively Low Mechanical Strength

Compared to engineering plastics like PEEK or metals, PTFE is a soft material. It is not suitable for components that require high tensile strength or rigidity on their own.

Susceptibility to Creep

Under sustained compressive load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as "cold flow," must be factored into the design of seals and load-bearing components.

Specialized Machining Knowledge

While highly machinable, achieving precision with PTFE requires expertise. Improper tool selection, speeds, or feeds can lead to part deformation, poor surface finish, or internal stresses.

Making the Right Choice for Your Application

Your final design should be dictated by your primary operational goal.

- If your primary focus is purity and biocompatibility: Specify Virgin PTFE to ensure no fillers or additives are present, making it ideal for medical or pharmaceutical use.

- If your primary focus is sealing in harsh environments: Design custom gaskets or seals that leverage PTFE's chemical inertness and thermal stability.

- If your primary focus is low-friction movement: Machine custom bearings, slide plates, or non-stick surfaces to take advantage of PTFE's exceptionally low coefficient of friction.

- If your primary focus is electrical isolation: Create custom insulators that capitalize on PTFE's high dielectric strength and heat resistance.

By understanding these principles, you can precisely tailor PTFE components to solve your most demanding engineering challenges.

Summary Table:

| Key PTFE Property | Ideal for Custom Applications |

|---|---|

| Chemical Inertness | Seals, gaskets, tank linings for harsh environments |

| Low Friction | Bearings, slide plates, non-stick surfaces |

| High Heat Resistance | Components operating up to 260°C (500°F) |

| Electrical Insulation | High-performance insulators and connectors |

| Biocompatibility (Virgin PTFE) | Surgical instruments, prosthetic devices, high-purity systems |

Ready to solve your unique engineering challenge with custom PTFE components?

At KINTEK, we specialize in precision machining of PTFE parts—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures your custom parts are designed to leverage PTFE's full advantages while accounting for its specific properties.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance