Yes, significant regulations and restrictions are actively being developed for Polytetrafluoroethylene (PTFE) and the entire class of chemicals known as PFAS. Driven by growing concerns over environmental persistence and human health, the regulatory landscape is shifting from targeting individual compounds to restricting the entire group, including widely used polymers like PTFE.

The core takeaway is that while PTFE remains approved for many applications today, a major regulatory shift is underway, particularly in the EU. Businesses must now treat the continued use of PTFE as a significant long-term risk and proactively evaluate alternatives to future-proof their products and supply chains.

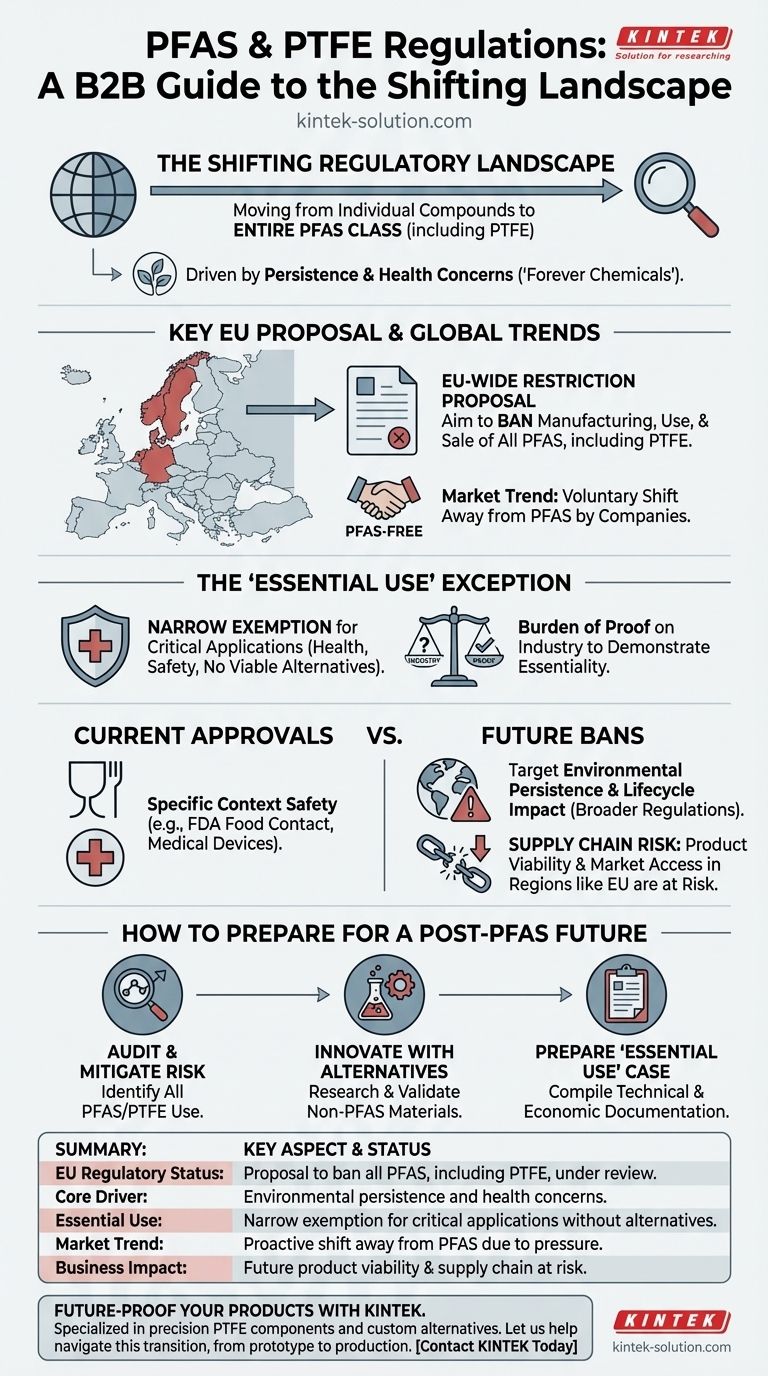

The Shifting Regulatory Landscape for PFAS

The approach to regulating PFAS chemicals is becoming broader and more aggressive. This reflects a fundamental change in how authorities view the risks associated with this family of "forever chemicals."

The Proposed EU-Wide Restriction

The most significant pending action is a proposal within the European Union. Five member states—Germany, the Netherlands, Denmark, Sweden, and Norway—have formally submitted a plan to restrict all PFAS as a group.

This proposal aims to ban the manufacturing, use, and sale of PFAS, explicitly including fluoropolymers like PTFE. The stated goal is to minimize human and environmental exposure to these persistent substances.

The "Essential Use" Exception

The proposed EU ban is not absolute and includes a provision for "essential uses." This concept acknowledges that for certain critical applications, no viable alternatives to PFAS may exist.

However, the definition of "essential" is expected to be extremely narrow. It will likely cover uses critical for health, safety, and the functioning of society where substitutes are technically or economically unfeasible. The burden of proof will fall on industry to demonstrate that a specific use is truly essential.

Market Reaction Precedes Regulation

Beyond formal government action, the market itself is driving change. A growing number of companies are voluntarily moving away from PTFE and other PFAS in their products.

This shift is a response to increasing public awareness, customer demand for safer products, and the desire to mitigate future regulatory and reputational risks.

Understanding the Implications for Your Business

This regulatory momentum creates tangible challenges for any organization that relies on PTFE. It is no longer a question of if restrictions will impact operations, but when and to what degree.

Current Approvals vs. Future Bans

It is critical to distinguish between current application-specific approvals and future environmental regulations. For example, PTFE is widely recognized as meeting FDA standards for food contact and biocompatibility requirements for some medical devices.

These approvals certify its safety in a specific context. However, they do not protect it from broader, environmentally-focused regulations that target the chemical's persistence and lifecycle impact.

Supply Chain and Product Viability

A widespread ban, even with exceptions, will create significant supply chain disruption. If your product incorporates PTFE, its future market access in regions like the EU is at risk.

This requires a fundamental re-evaluation of material selection. Relying on a substance class that is the target of a global regulatory phase-out is a precarious long-term strategy.

How to Prepare for a Post-PFAS Future

Navigating this change requires a proactive, strategic approach rather than a reactive one. The goal is to build resilience and maintain a competitive advantage.

- If your primary focus is risk mitigation: Begin a comprehensive audit of your products and supply chain to identify every instance of PTFE or other PFAS use immediately.

- If your primary focus is innovation: Start actively researching and validating non-PFAS alternative materials to get ahead of regulations and meet growing customer demand for sustainability.

- If you believe your application is an "essential use": Start compiling the technical and economic documentation to prove that no viable alternatives exist for your specific, critical function.

Proactive adaptation, not reactive compliance, will define success in this evolving regulatory environment.

Summary Table:

| Key Aspect | Current Status & Implication |

|---|---|

| EU Regulatory Status | Proposal to ban all PFAS, including PTFE, is under review. |

| Core Driver | Environmental persistence and health concerns over 'forever chemicals'. |

| 'Essential Use' Exception | A narrow exemption for critical applications with no viable alternatives. |

| Market Trend | Companies are proactively shifting away from PFAS due to consumer and investor pressure. |

| Business Impact | Future product viability and supply chain stability for PTFE-dependent products are at risk. |

Future-Proof Your Products with High-Performance, Custom PTFE Alternatives

The evolving regulatory landscape for PFAS requires a proactive partner. KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical need for material performance and compliance.

Let us help you navigate this transition. Whether you need to explore custom-fabricated alternatives or require documentation support for an 'essential use' case, our expertise from prototype to high-volume production is your advantage.

Contact KINTEK today to discuss your specific application and build a resilient, compliant supply chain.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the main applications of PTFE material? Unlock Superior Performance in Demanding Industries

- What are the applications of PTFE dispersion? A Guide to Non-Stick, Chemical-Resistant Coatings & More

- What are the key characteristics of PTFE (Teflon)? Unlock Superior Chemical & Thermal Performance

- How is PTFE used in the beauty industry? Enhance Product Performance and Safety

- What are the temperature range and mechanical properties of PTFE? The Ultimate Guide to Performance

- What are the unique properties of PTFE? A Guide to High-Performance CNC Machining

- Why is water used in PTFE polymerization? The Essential Role of Water in Creating High-Performance PTFE

- How was Teflon discovered and when was it commercialized? The Accidental Invention of a Wonder Polymer