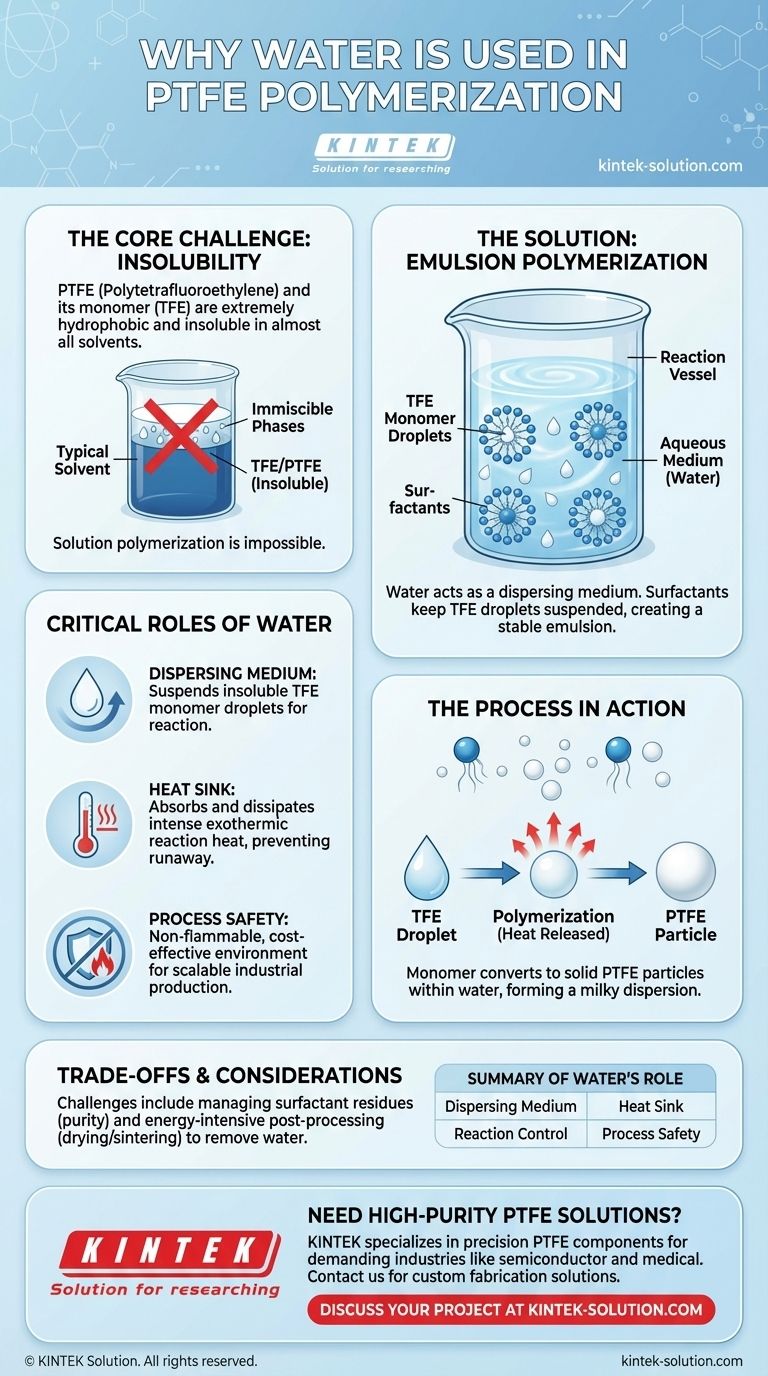

In short, water is used because Polytetrafluoroethylene (PTFE) is a uniquely challenging material that is insoluble in virtually all known solvents. This forces manufacturers to use a method called emulsion polymerization, where water acts as a safe, inert medium to disperse the ingredients and control the intense heat of the reaction.

The core challenge in making PTFE is not chemical, but physical. Since the monomer and the final polymer will not dissolve, water serves as a suspension and heat-transfer medium, making it the only practical environment to control the polymerization process at an industrial scale.

The Core Challenge: Polymerizing an Insoluble Material

To understand why water is essential, we must first appreciate the unique properties of the materials involved in making PTFE.

The Problem of Extreme Insolubility

Most plastics are made through solution polymerization, where the monomer (the basic chemical building block) is dissolved in a solvent. The reaction proceeds smoothly in the liquid phase.

This is impossible with PTFE. Both the starting monomer, tetrafluoroethylene (TFE), and the final polymer, PTFE, are extremely hydrophobic and do not dissolve in any practical solvent. Attempting to polymerize it without a medium would be uncontrollable and inefficient.

Why Water is the Ideal Medium

Water isn't used as a solvent but as a dispersing medium. It provides a liquid environment where the insoluble TFE monomer can be suspended as tiny droplets.

Furthermore, water is cheap, non-flammable, and has a high heat capacity, making it perfect for the industrial process.

How Emulsion Polymerization Solves the Problem

The specific process used is called emulsion polymerization. It leverages water's properties to create a stable and controllable reaction environment.

Creating a Stable Emulsion

To keep the TFE monomer droplets suspended evenly in water, surfactants (essentially industrial soaps) are added. The surfactant molecules coat the TFE droplets, preventing them from clumping together and creating a stable emulsion with a massive surface area for the reaction to occur.

Managing Dangerous Reaction Heat

Polymerization is a highly exothermic process, meaning it releases a tremendous amount of heat. If this heat is not managed, it can lead to a runaway reaction, damaging the equipment and creating a low-quality product.

Water is an exceptional heat sink. It absorbs and dissipates this energy efficiently, allowing for precise temperature control and ensuring the formation of a consistent, high-molecular-weight polymer.

Forming the Final Product

As the reaction proceeds, the TFE monomer converts into solid PTFE within the stabilized droplets. The result is not a solid block of plastic but a milky-white liquid dispersion of fine PTFE particles suspended in water. This dispersion is easy to handle and can be processed into powders, coatings, or solid forms.

Understanding the Trade-offs

While necessary, using an aqueous process introduces specific challenges and consequences that are critical to understand.

The Purity and Environmental Challenge

The surfactants required for the process are a major point of concern. Historically, compounds like PFOA were used, which are now known to be persistent environmental pollutants with significant health risks.

These surfactants can remain as trace impurities in the final PTFE product and must be managed carefully in the manufacturing wastewater. Modern processes now use newer, less persistent types of surfactants.

The Need for Post-Processing

The direct output of polymerization is a water-based dispersion. To produce the final solid PTFE material used in products, this water must be removed through complex and energy-intensive drying and sintering (heating to fuse the particles) steps.

Making the Right Choice for Your Goal

Understanding this process helps inform decisions when specifying or working with PTFE materials.

- If your primary focus is process safety and scalability: Recognize that the water-based emulsion process is the industry standard precisely because it is the most effective method for controlling the reaction's heat and safely producing PTFE at scale.

- If your primary focus is material purity: Be aware that all PTFE made this way will contain trace amounts of surfactants from the manufacturing process, which may be a concern for ultra-sensitive applications like semiconductor manufacturing or medical implants.

- If your primary focus is environmental impact: Inquire about the specific types of surfactants used by the manufacturer, favoring those who have transitioned to newer, less persistent chemistries to minimize environmental harm.

Ultimately, water is the indispensable enabler, providing the physical environment required to create this uniquely high-performance polymer.

Summary Table:

| Role of Water in PTFE Polymerization | Key Benefit |

|---|---|

| Dispersing Medium | Suspends insoluble TFE monomer droplets |

| Heat Sink | Absorbs and dissipates intense reaction heat |

| Reaction Control | Enables stable, scalable emulsion polymerization |

| Process Safety | Provides a non-flammable, cost-effective environment |

Need High-Purity PTFE Components for Demanding Applications?

At KINTEK, we understand the critical balance between material performance, purity, and manufacturability. Our expertise in PTFE fabrication ensures that components like seals, liners, and labware meet the stringent requirements of the semiconductor, medical, and laboratory industries.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, helping you achieve optimal performance and reliability.

Contact us today to discuss your specific PTFE needs and learn how we can support your project with tailored solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE perform as an electrical insulator? Unmatched Signal Integrity & High-Voltage Reliability

- What is the temperature resistance range of PTFE? Mastering Extreme Heat and Cold for Demanding Applications

- What are the benefits of adding fillers to PTFE? Enhance Wear, Strength, and Performance

- How is PTFE applied in hydrogen energy applications? Ensuring Safety and Efficiency in H2 Systems

- What are the common filler materials used in RPTFE and their purposes? Enhance PTFE Performance for Demanding Applications

- How is Teflon applied in the medical sector? Unlocking Biocompatibility and Sterility for Healthcare

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What are the common applications of Teflon? Discover Its Versatility Across Industries