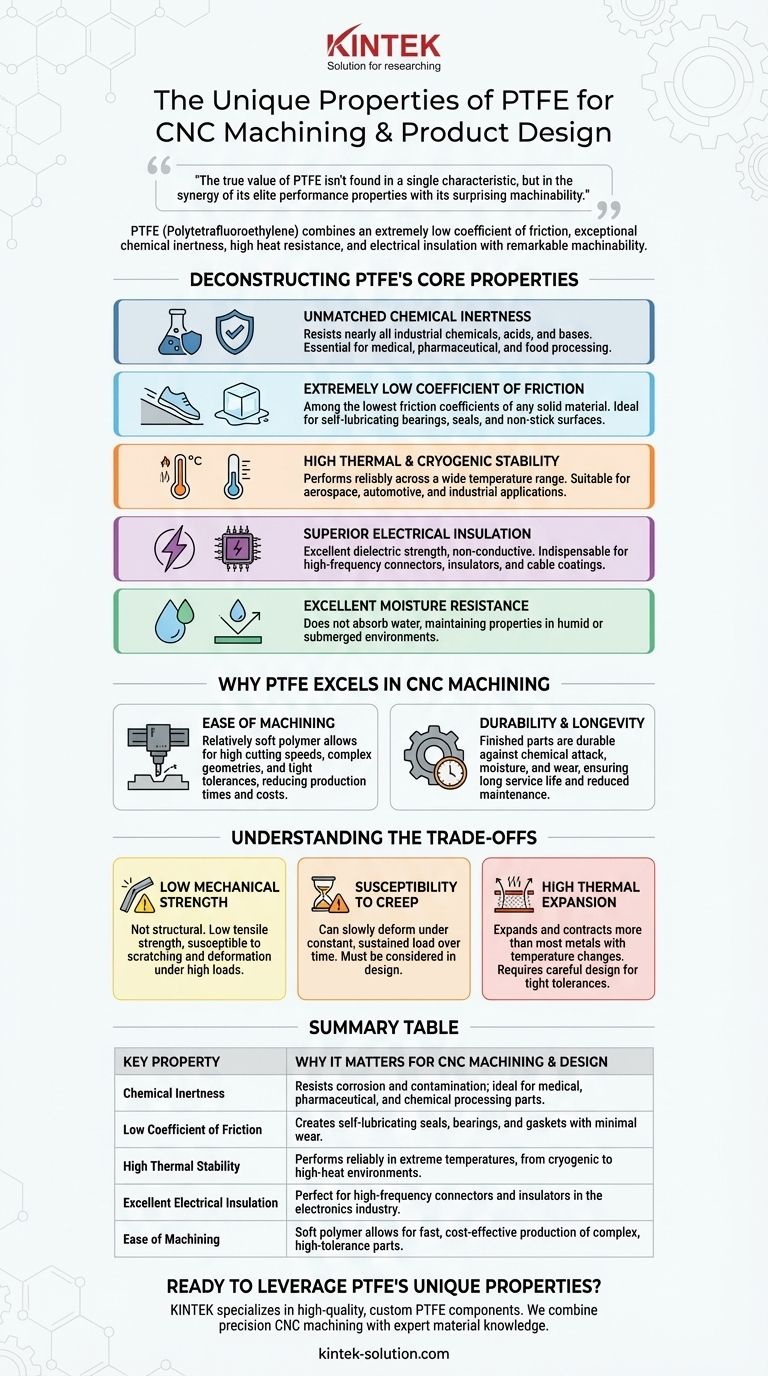

At its core, Polytetrafluoroethylene (PTFE) is uniquely suited for CNC machining and product design due to its rare combination of properties. It possesses an extremely low coefficient of friction, exceptional chemical inertness, high heat resistance, and excellent electrical insulation, all within a material that is remarkably easy to machine into precise, complex shapes.

The true value of PTFE isn't found in a single characteristic, but in the synergy of its elite performance properties with its surprising machinability. This allows engineers to solve demanding challenges in harsh environments where most other polymers would fail.

Deconstructing PTFE's Core Properties

To understand why PTFE is such a valuable material, we must examine its fundamental characteristics. Each property addresses a specific set of engineering problems.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive materials known. It resists nearly all industrial chemicals, acids, and bases, preventing corrosion and contamination.

This makes it an essential material for components in the medical, pharmaceutical, and food processing industries where purity and resistance to aggressive cleaning agents are critical.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material, often compared to wet ice on wet ice. This inherent slipperiness means it requires no external lubrication.

This property is ideal for creating high-performance bearings, seals, gaskets, and non-stick surfaces where minimizing wear and resistance is the primary goal.

High Thermal and Cryogenic Stability

The material can perform reliably across an exceptionally wide temperature range. It maintains its properties at high temperatures and also exhibits good performance in cryogenic conditions.

This thermal stability makes it a go-to choice for components in aerospace, automotive, and industrial applications that experience extreme temperature fluctuations.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength. It does not conduct electricity and resists electrical breakdown even at high frequencies.

This makes it indispensable in the electronics industry for creating high-performance insulators, connectors, and cable coatings, especially for high-frequency applications.

Excellent Moisture Resistance

The material does not absorb water. This moisture resistance ensures that its mechanical and electrical properties remain stable even in humid or submerged environments.

Why PTFE Excels in CNC Machining

A material's properties are only useful if it can be cost-effectively shaped. PTFE's structure makes it exceptionally well-suited for computer numerical control (CNC) machining.

Ease of Machining

PTFE is a relatively soft polymer, which allows for high cutting speeds and feeds during the CNC machining process. This translates to faster production times and lower manufacturing costs.

Its machinability allows for the creation of highly complex geometries and parts with very tight tolerances, which is crucial for precision engineering.

Durability and Longevity

Despite its softness, finished PTFE components are highly durable within their intended applications. Their resistance to chemical attack, moisture, and wear from friction ensures a long service life.

This longevity reduces maintenance costs and component failure rates, particularly in critical systems found in aerospace or medical devices.

Understanding the Trade-offs

No material is perfect. To use PTFE effectively, it is critical to understand its limitations. Its greatest strengths are directly linked to its weaknesses.

Low Mechanical Strength

PTFE is not a structural material. It has relatively low tensile strength and is not suitable for high-load or high-impact applications on its own.

Its inherent softness means it can be easily scratched or deformed by sharp objects.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in any design where a component will be under continuous pressure.

High Thermal Expansion

While it operates well at temperature extremes, PTFE has a high coefficient of thermal expansion. This means it will expand and contract more than most metals with temperature changes, a factor that must be considered when designing assemblies with tight tolerances.

Making the Right Choice for Your Design

Selecting PTFE depends entirely on the primary goal of your component. Its unique profile makes it an ideal choice for some applications and a poor choice for others.

- If your primary focus is low friction and chemical resistance: PTFE is an industry-leading choice for seals, gaskets, bushings, and non-stick surfaces in harsh environments.

- If your primary focus is electrical insulation: Its high dielectric strength makes it a top-tier material for high-frequency connectors and insulators.

- If your primary focus is high mechanical strength or structural integrity: You should consider a different polymer or a filled grade of PTFE, as its inherent softness and tendency to creep are significant limitations.

Ultimately, PTFE is a specialized polymer that excels at solving engineering problems that most other materials simply cannot address.

Summary Table:

| Key Property | Why It Matters for CNC Machining & Design |

|---|---|

| Chemical Inertness | Resists corrosion and contamination; ideal for medical, pharmaceutical, and chemical processing parts. |

| Low Coefficient of Friction | Creates self-lubricating seals, bearings, and gaskets with minimal wear. |

| High Thermal Stability | Performs reliably in extreme temperatures, from cryogenic to high-heat environments. |

| Excellent Electrical Insulation | Perfect for high-frequency connectors and insulators in the electronics industry. |

| Ease of Machining | Soft polymer allows for fast, cost-effective production of complex, high-tolerance parts. |

Ready to leverage PTFE's unique properties for your precision components?

KINTEK specializes in manufacturing high-quality, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine precision CNC machining with expert material knowledge to deliver solutions that meet your most demanding requirements, from prototypes to high-volume orders.

Contact us today to discuss your project and discover how our PTFE expertise can benefit your design.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability