In the beauty industry, Polytetrafluoroethylene (PTFE) is a specialized performance ingredient used in two primary areas. It is integrated into nail polish formulations to create a smooth, crack-resistant finish and applied as a coating on high-temperature hair styling tools like straighteners and curling irons.

At its core, PTFE is not used for aesthetic reasons but for its functional properties. Its unique combination of extreme heat resistance, chemical inertness, and low-friction surface makes it a powerful problem-solver for enhancing the durability and safety of beauty products and tools.

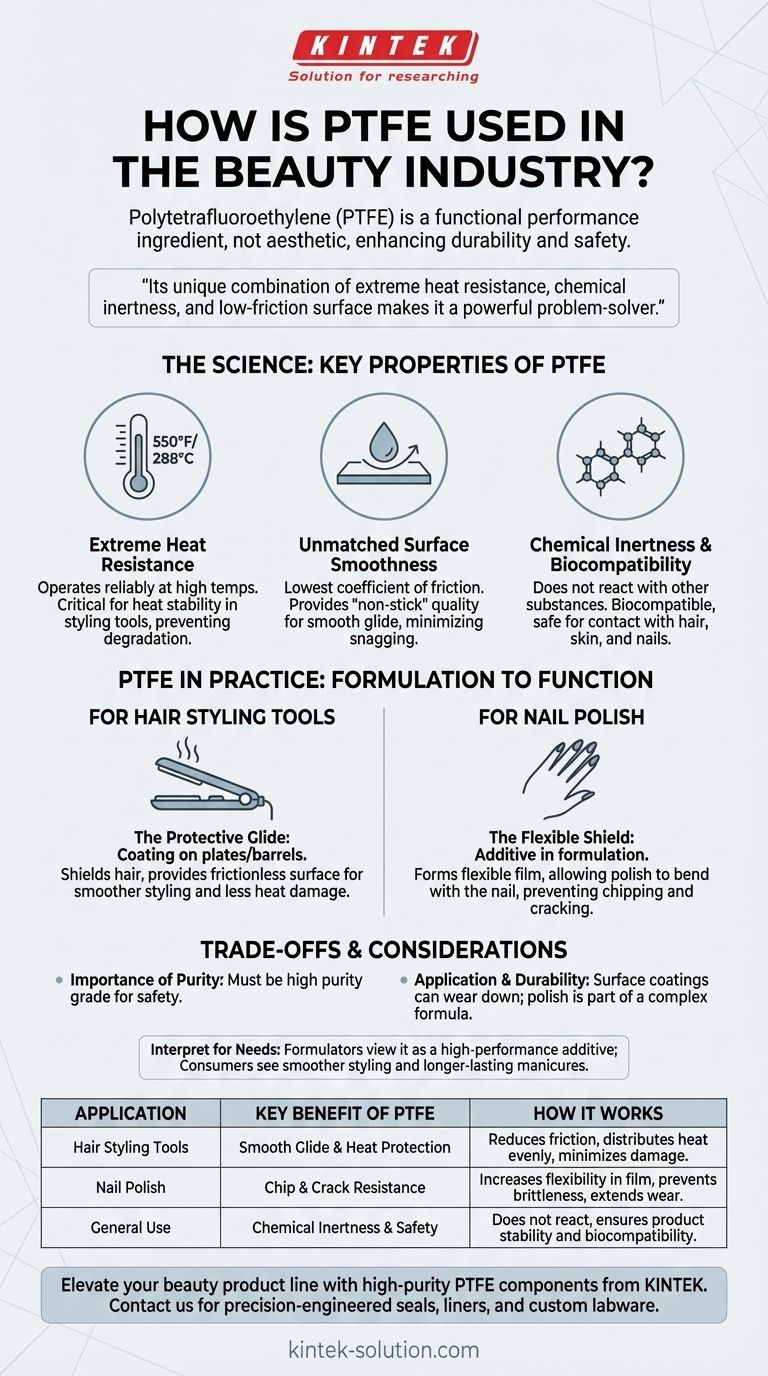

The Science Behind the Application: Key Properties of PTFE

The decision to use PTFE in beauty applications is driven by a few distinct and powerful material characteristics. These properties solve specific challenges in product formulation and device engineering.

Extreme Heat Resistance

PTFE is renowned for its ability to withstand very high temperatures, operating reliably up to 550°F (288°C).

This thermal stability is critical for hair styling tools. It allows straightener plates and curling iron barrels to be coated with a material that will not degrade, melt, or release fumes at the high temperatures required for effective styling.

Unmatched Surface Smoothness (Low Friction)

PTFE has one of the lowest coefficients of friction of any known solid, giving it a signature "non-stick" quality.

In hair tools, this translates to an exceptionally smooth glide that minimizes snagging and pulling, reducing hair breakage and damage. In nail polish, it helps the formula flow evenly, creating a flawless, uniform surface that resists imperfections.

Chemical Inertness and Biocompatibility

PTFE is chemically inert, meaning it does not react with other substances. The references also highlight its biocompatibility, which is why it is trusted for medical applications like implants and catheters.

This inertness is vital in nail polish, ensuring the PTFE does not interfere with other ingredients like pigments, solvents, or resins. Its biocompatible nature means it is considered safe for contact with hair, skin, and nails.

PTFE in Practice: From Formulation to Function

Understanding the core properties of PTFE makes its practical applications in beauty products clear and logical.

For Hair Styling Tools: The Protective Glide

When applied to the plates of a flat iron or the barrel of a curling iron, a PTFE coating acts as a protective barrier.

This coating serves two functions: it shields the hair from direct, harsh contact with the heating element and provides a frictionless surface. The result is smoother styling, more even heat distribution, and a marked reduction in mechanical stress and damage to the hair cuticle.

For Nail Polish: The Flexible Shield

Within a nail polish formulation, PTFE acts as a performance-enhancing additive. It contributes to the formation of a protective film on the nail.

This film provides a smoother finish and, more importantly, imparts flexibility. This flexibility allows the dried polish to bend slightly with the nail instead of becoming rigid and brittle, which is the primary reason for its improved resistance to chipping and cracking.

Understanding the Trade-offs and Considerations

While PTFE offers significant functional benefits, it's important to view it within a complete context. Its effectiveness is not absolute and depends on quality and application.

The Importance of Purity and Grade

Not all PTFE is created equal. As with its use in the medical or semiconductor industries, the PTFE intended for cosmetic use or on consumer appliances must be of a high purity grade. This ensures it is free from contaminants and safe for its intended purpose.

Application and Durability

For hair tools, a PTFE coating is a surface treatment that can wear down over time with repeated use and cleaning. As the coating degrades, its non-stick and protective benefits will diminish.

In nail polish, PTFE is just one component in a complex formula. While it enhances crack resistance, the overall longevity of a manicure still depends on base coats, top coats, and other formulation ingredients.

How to Interpret This for Your Needs

Your perspective on PTFE will depend on your specific goal, whether you are developing a product or simply using one.

- If you are a product formulator or engineer: View PTFE as a high-performance additive for improving mechanical properties, such as flexibility in films or heat resistance and lubricity in surface coatings.

- If you are a salon professional or informed consumer: Recognize that the inclusion of PTFE translates to tangible benefits like smoother, less damaging hair styling and longer-lasting, more chip-resistant manicures.

Understanding the specific properties of PTFE allows you to see it not just as an ingredient, but as a targeted solution for performance and safety in modern beauty products.

Summary Table:

| Application | Key Benefit of PTFE | How It Works |

|---|---|---|

| Hair Styling Tools | Smooth Glide & Heat Protection | PTFE coating on plates/barrels reduces friction and distributes heat evenly, minimizing hair damage. |

| Nail Polish | Chip & Crack Resistance | PTFE additive increases flexibility in the polish film, preventing brittleness and extending wear. |

| General Use | Chemical Inertness & Safety | PTFE does not react with other ingredients, ensuring product stability and biocompatibility for skin/nail contact. |

Elevate your beauty product line with high-purity PTFE components from KINTEK.

Whether you're developing advanced hair styling tools, durable nail polish, or other cosmetic innovations, our precision-engineered PTFE seals, liners, and custom labware can enhance performance, safety, and durability. We specialize in custom fabrication—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors.

Contact us today to discuss how our PTFE solutions can meet your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications