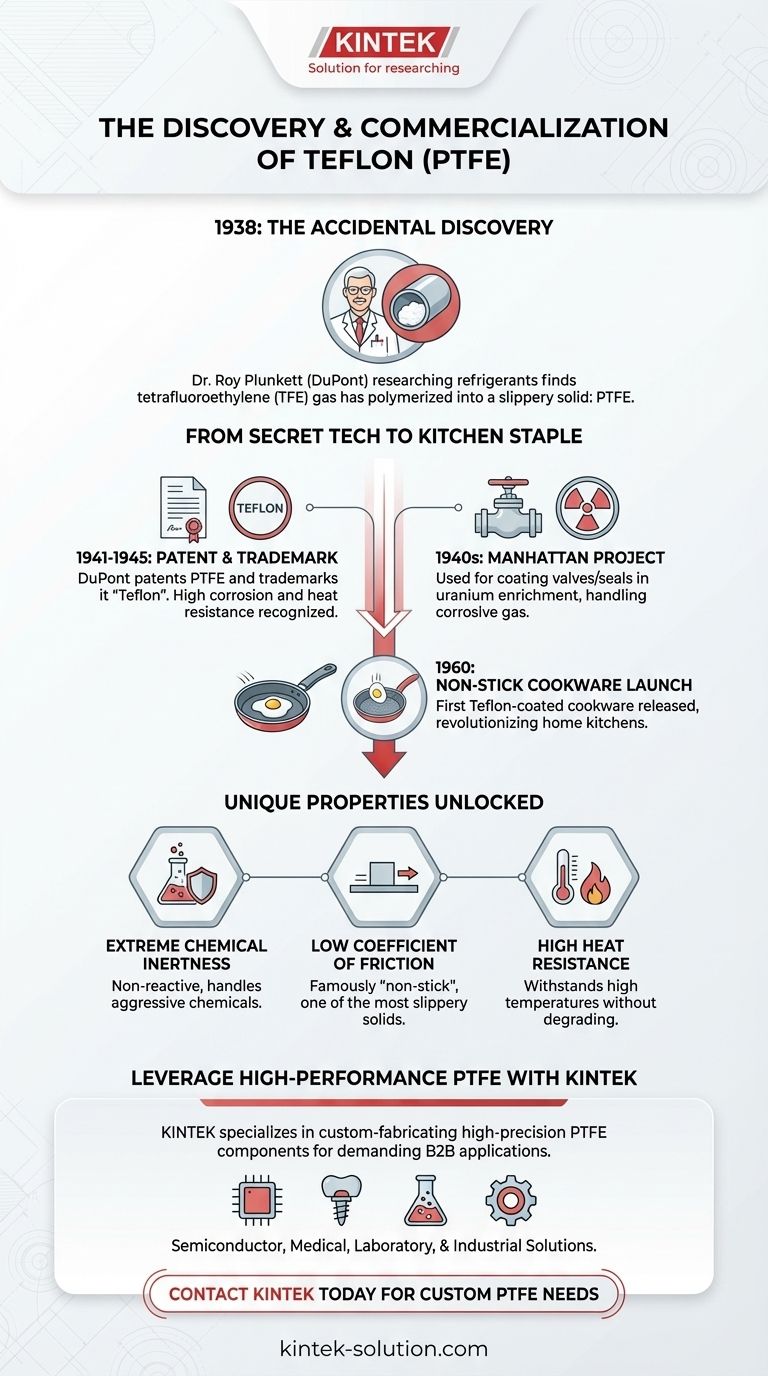

Teflon was discovered by accident in 1938 by a chemist named Dr. Roy Plunkett while he was working for DuPont. He was attempting to create a new refrigerant gas but instead created a mysterious, slippery solid. DuPont patented the material in 1941 and began marketing it under the "Teflon" trademark in 1945, but it wasn't used for its most famous application, non-stick cookware, until 1960.

The discovery of Teflon is a classic story of scientific serendipity. An attempt to create a new refrigerant resulted in an entirely new category of material whose unique properties were so advanced that it took over two decades to find its most famous consumer application.

The Accidental Discovery of a "Miracle" Polymer

The Refrigerant Experiment

In 1938, Dr. Roy Plunkett was researching new, non-toxic refrigerants for DuPont. His work involved experimenting with a gas called tetrafluoroethylene (TFE).

A Pressurized Cylinder with a Surprise

Plunkett had stored TFE gas in a pressurized cylinder. One day, he opened the valve, but no gas came out, even though the cylinder's weight indicated it was still full.

Driven by curiosity, he cut the cylinder open. Inside, he didn't find a gas but rather a waxy, white, and remarkably slippery solid that coated the inner walls.

Identifying Polytetrafluoroethylene (PTFE)

The TFE gas had spontaneously polymerized, creating a new substance: polytetrafluoroethylene, or PTFE. This material, the result of a complete accident, was found to have a unique and valuable set of properties.

From Secret Military Tech to Kitchen Staple

The Patent and Early Use

DuPont's scientists immediately recognized the potential of this new material. It was extremely resistant to corrosion and heat. The company patented PTFE in 1941 and trademarked it as Teflon in 1945.

Its first significant application was for the Manhattan Project during World War II. The material's ability to resist the highly corrosive uranium hexafluoride gas made it invaluable for coating valves and seals.

The Birth of Non-Stick Cookware

While Teflon had found critical industrial uses, its path to the public was much slower. It wasn't until 1960 that DuPont released the first non-stick cookware with a Teflon coating, forever changing the home kitchen.

Understanding Teflon's Unique Properties

Extreme Chemical Inertness

The reason Teflon was so useful in the Manhattan Project is its incredible resistance to corrosion. It is one of the most non-reactive substances known, which is why it is used to handle highly aggressive chemicals.

A Remarkably Low Coefficient of Friction

This is the property that makes Teflon famously "non-stick." Very few materials will adhere to its surface, making it one of the most slippery solids ever discovered.

High Heat Resistance

Teflon can withstand high temperatures without degrading, a property essential for its use in demanding industrial applications and, of course, for cooking.

The Key Takeaways from Teflon's History

The story of Teflon's discovery and commercialization offers clear lessons for innovation and business.

- If your primary focus is on scientific innovation: Recognize that some of the most impactful discoveries are born from unexpected accidents and a willingness to investigate anomalies.

- If your primary focus is on business and marketing: Understand that the timeline from invention to a successful consumer product can be long, often requiring the right application to unlock a material's true market potential.

- If your primary focus is on material science: Appreciate that Teflon's value comes from a rare combination of properties—chemical inertness, heat resistance, and low friction—that made it a solution waiting for a problem.

Teflon's journey from a laboratory anomaly to a household name is a powerful testament to the value of recognizing potential in the unexpected.

Summary Table:

| Event | Year | Key Detail |

|---|---|---|

| Accidental Discovery | 1938 | Dr. Roy Plunkett at DuPont found PTFE while experimenting with refrigerants. |

| Patent Filed | 1941 | DuPont patented the new polymer, polytetrafluoroethylene (PTFE). |

| Trademark Registered | 1945 | The material was trademarked under the name "Teflon." |

| First Major Application | 1940s | Used for seals and valves in the Manhattan Project due to its corrosion resistance. |

| Consumer Product Launch | 1960 | The first Teflon-coated non-stick cookware was introduced to the public. |

Leverage the Power of High-Performance PTFE in Your Projects

The story of Teflon shows that a material's true potential is unlocked when it meets the right application. At KINTEK, we specialize in custom-fabricating high-precision PTFE components—including seals, liners, and labware—that harness these same remarkable properties for your most demanding challenges.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get components that offer superior chemical resistance, non-stick performance, and thermal stability.

Ready to solve your unique material challenge? Contact KINTEB today to discuss your custom PTFE needs, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech