Yes, PTFE V-Rings are highly customizable. The inherent properties of Polytetrafluoroethylene (PTFE), particularly its machinability and its ability to be blended with various fillers, allow for the creation of seals tailored to precise application requirements, from unique dimensions to enhanced performance characteristics.

The key is to understand that customization extends beyond simple size and shape. It involves fundamentally altering the material's composition to achieve specific engineering outcomes, such as increased durability, different hardness, or compatibility with specialized environments.

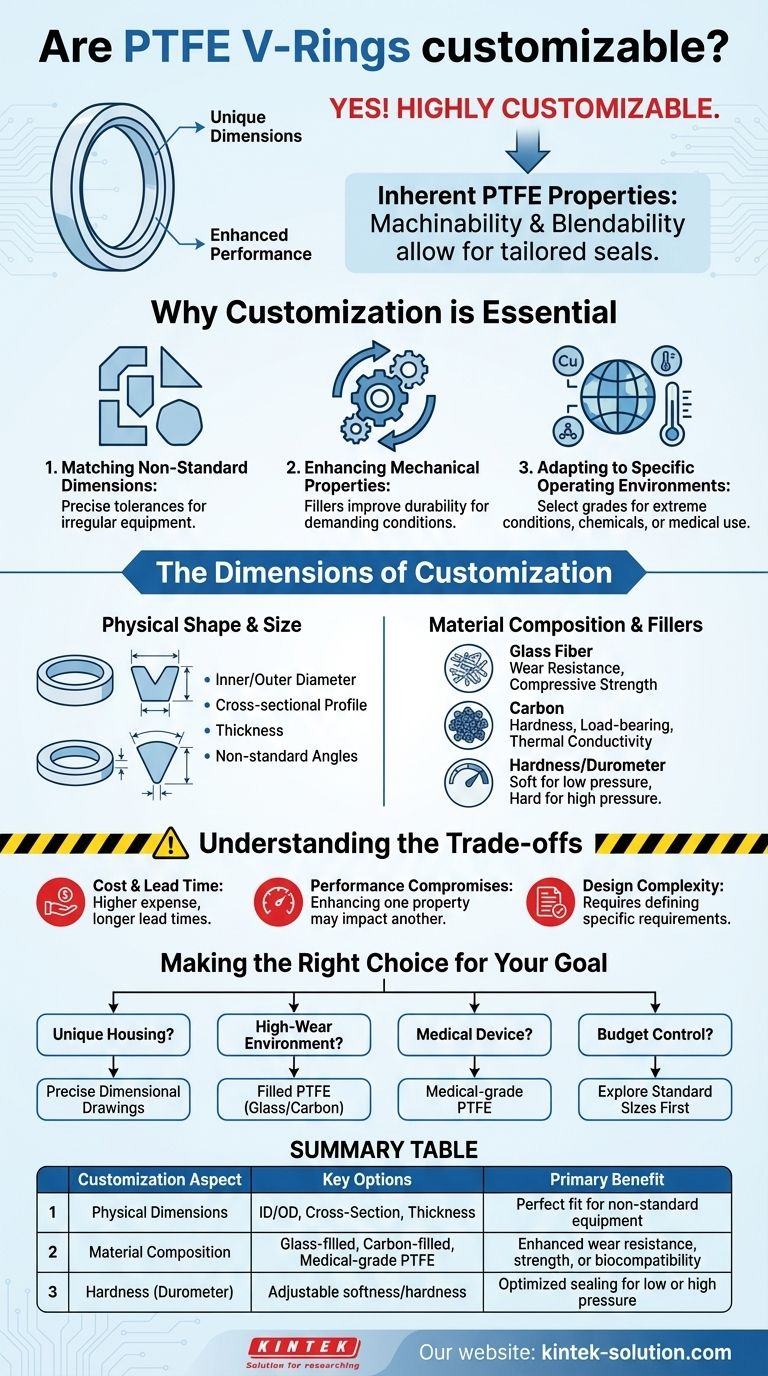

Why Customization is Essential for Sealing Applications

Standard, off-the-shelf components are designed for common applications. However, many industrial, medical, and high-performance systems present unique challenges that demand a tailored solution.

Matching Non-Standard Dimensions

Many designs involve unique housing or shaft dimensions that do not conform to standard sizes. Custom machining allows V-Rings to be manufactured to precise tolerances, ensuring a perfect fit for irregularly shaped or custom-built equipment.

Enhancing Mechanical Properties

Base PTFE is known for its low friction and chemical inertness, but it can be soft. By adding fillers, its mechanical properties can be significantly improved to handle more demanding conditions.

Adapting to Specific Operating Environments

A standard V-Ring may not be suitable for extreme temperatures, aggressive chemicals, or sterile medical applications. Customization allows for the selection of specific PTFE grades and fillers to ensure reliability and safety in these unique contexts.

The Dimensions of Customization

Understanding what can be changed is the first step in specifying the right part. Customization typically falls into two main categories: physical form and material composition.

Physical Shape and Size

This is the most straightforward form of customization. PTFE V-Rings can be machined to virtually any inner diameter, outer diameter, or cross-sectional profile required by the design. This includes creating versions with specific thicknesses or non-standard angles.

Material Composition and Fillers

This is where performance engineering truly begins. Different fillers are blended with the base PTFE resin to enhance specific properties.

Common fillers include glass fiber to increase wear resistance and compressive strength or carbon to improve hardness, load-bearing capability, and thermal conductivity. The percentage and type of filler are customized based on the application's demands.

Hardness and Durometer

The hardness of the final PTFE material can be adjusted. A softer material might provide a better seal in a low-pressure application, while a harder, filled compound would be necessary to prevent extrusion under high pressure.

Understanding the Trade-offs

While customization offers significant advantages, it's crucial to approach it with a clear understanding of the associated trade-offs.

Cost and Lead Time

Custom-machined parts are almost always more expensive than mass-produced, standard components, especially in lower volumes. The process also requires longer lead times for design, tooling (if any), and manufacturing.

Performance Compromises

Enhancing one property with a filler can sometimes impact another. For example, adding glass fiber to improve wear resistance may slightly decrease the material's chemical compatibility against certain aggressive media. It is a balancing act based on the primary need.

Design Complexity

Specifying a custom part requires a deeper technical understanding of the application's requirements. You must be able to clearly define operating pressures, temperatures, media, and desired performance characteristics to the manufacturer.

Making the Right Choice for Your Goal

To specify the correct part, you must first define your most critical requirement.

- If your primary focus is fitting a unique housing: Provide precise dimensional drawings with clear tolerances to ensure an exact fit.

- If your primary focus is durability in a high-wear environment: Specify a V-Ring made from a filled PTFE, such as a glass- or carbon-filled compound.

- If your primary focus is a medical device: Ensure you specify a medical-grade PTFE that meets all necessary regulatory and biocompatibility standards.

- If your primary focus is budget control: Thoroughly investigate all available standard V-Ring sizes and materials before committing to the higher cost of a custom solution.

By leveraging the full scope of PTFE customization, you can move beyond a standard component and engineer a sealing solution that perfectly meets your application's demands.

Summary Table:

| Customization Aspect | Key Options | Primary Benefit |

|---|---|---|

| Physical Dimensions | Inner/Outer Diameter, Cross-Section, Thickness | Perfect fit for non-standard equipment |

| Material Composition | Glass-filled, Carbon-filled, Medical-grade PTFE | Enhanced wear resistance, strength, or biocompatibility |

| Hardness (Durometer) | Adjustable softness or hardness | Optimized sealing for low or high-pressure applications |

Ready to engineer the perfect PTFE V-Ring for your specific needs?

KINTEK specializes in custom fabrication of high-performance PTFE components, including seals, liners, and labware. Whether you need a prototype or a high-volume order for the semiconductor, medical, laboratory, or industrial sectors, our precision manufacturing ensures a perfect seal that meets your exact dimensional, material, and performance requirements.

Contact our experts today to discuss your project and receive a customized solution that enhances your equipment's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability