The most direct reason ink appears on a Teflon sheet is that residual ink or transfer material is being lifted from the garment during a second press. When the item is reheated, any ink that did not fully bond with the fabric can reactivate and transfer upwards onto the protective sheet.

This isn't just a cleaning issue; it's a critical indicator of your transfer process. Ink on your Teflon sheet signals that excess, unbonded ink is escaping, which can compromise the quality of your current and future projects.

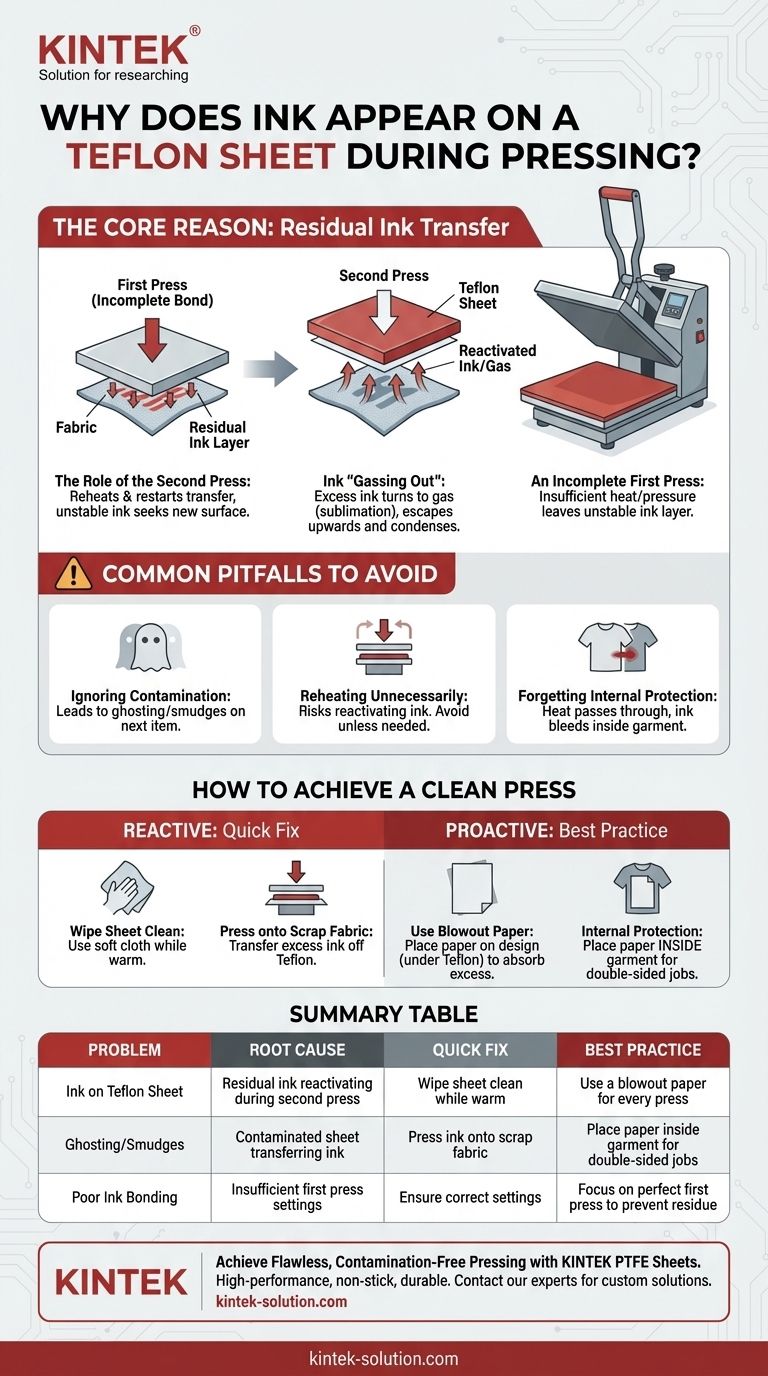

The Core Reason: Residual Ink Transfer

Understanding why ink is left behind is the first step to preventing it. The problem originates from the conditions of the initial press, even though it only becomes visible during a subsequent one.

The Role of the Second Press

A second press is a common point of failure. This often occurs when setting a design, pressing a double-sided garment, or simply trying to flatten the transfer area further.

This reheating process essentially re-starts the transfer, causing any unstable ink to seek a new surface to bond with—in this case, your hot Teflon sheet.

Ink "Gassing Out"

In processes like sublimation, ink converts to a gas to dye the fabric fibers. If there is more ink on the paper than the polyester fibers can absorb, this excess gas has nowhere to go.

During a second press, this trapped gas can escape upwards, condensing and solidifying on the cooler surface of the Teflon sheet.

An Incomplete First Press

The issue may also stem from an imperfect first press. If the pressure, temperature, or time was insufficient, the ink may not have fully and permanently bonded with the material.

This leaves a fine layer of unstable ink on the surface, ready to be lifted off the next time heat is applied.

Common Pitfalls to Avoid

Recognizing the scenarios where this is most likely to happen can help you diagnose the root cause of the problem and prevent it from ruining your next project.

Ignoring the Contamination

The most significant mistake is continuing to work without cleaning the sheet. The ink residue on the Teflon will transfer to the very next item you press.

This often results in a faint, blurry image known as "ghosting" or random smudges that can ruin a perfectly good blank.

Reheating the Same Area Unnecessarily

Each time you apply heat, you risk reactivating the ink. Avoid multiple presses on the same area unless it is absolutely required by your transfer material's instructions.

If you must press again, take preventative measures to protect your equipment and your garment.

Forgetting Internal Protection

When pressing double-sided items like t-shirts, the heat can pass through the top layer and reactivate the design on the other side.

This will cause the ink from the first side's design to bleed onto the inside of the garment or onto your heat press platen.

How to Achieve a Clean Press

You can address the problem reactively (cleaning) or proactively (preventing). For professional results, focus on prevention.

The Immediate Fix: Cleaning the Sheet

If you find ink on your Teflon, you must clean it before proceeding. You can wipe it down with a soft cloth while the sheet is still warm.

Alternatively, you can place a piece of scrap fabric or butcher paper over the sheet and press it. The excess ink will transfer off the Teflon and onto the scrap material.

The Best Practice: Using Blowout Paper

Prevention is always better than correction. A "blowout sheet" of plain butcher paper or copy paper placed on top of your design (under the Teflon) will absorb any excess ink.

For double-sided jobs, also place a sheet of paper inside the garment to catch any ink that might bleed through from the side you already pressed.

Making the Right Choice for Your Process

Your approach should depend on your quality standards and production volume.

- If your primary focus is a quick fix for a one-off job: Simply wipe the Teflon sheet clean between presses or press the residue onto a scrap piece of fabric.

- If your primary focus is achieving consistent, professional quality: Use a fresh sheet of protective butcher paper for every single press to absorb excess ink and guarantee no cross-contamination.

Ultimately, controlling your process variables is the key to flawless, repeatable results.

Summary Table:

| Problem | Root Cause | Quick Fix | Best Practice |

|---|---|---|---|

| Ink on Teflon Sheet | Residual ink reactivating during a second press | Wipe sheet clean while warm | Use a blowout paper for every press |

| Ghosting/Smudges | Contaminated sheet transferring ink to next item | Press ink onto scrap fabric | Place paper inside garment for double-sided jobs |

| Poor Ink Bonding | Insufficient pressure, temperature, or time on first press | Ensure correct settings for your material | Focus on a perfect first press to prevent residue |

Achieve Flawless, Contamination-Free Pressing with KINTEK PTFE Sheets

Is ink residue and ghosting compromising your product quality? KINTEK manufactures high-performance, non-stick PTFE (Teflon) sheets and components designed for durability and easy cleaning in demanding applications. Our sheets provide superior heat resistance and release properties, helping you maintain a clean pressing process.

We specialize in custom fabrication for the industrial and textile sectors, from prototypes to high-volume orders, ensuring you get the precise components you need.

Let's improve your process together. Contact our experts today for a consultation on how our PTFE solutions can enhance your production quality and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions