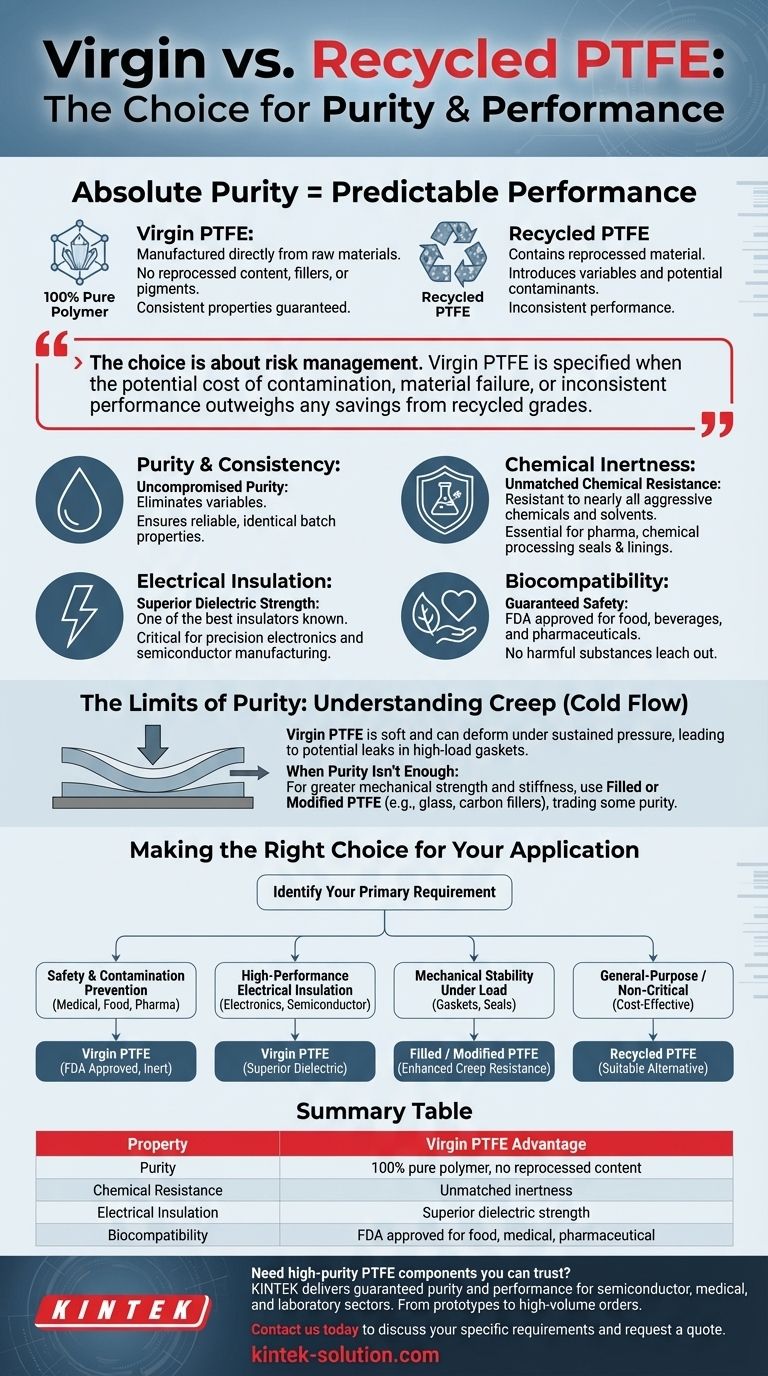

For applications demanding absolute purity and predictable performance, virgin Polytetrafluoroethylene (PTFE) is the only viable choice. Unlike recycled grades, virgin PTFE is manufactured directly from raw materials, containing no reprocessed content, fillers, or pigments. This 100% purity guarantees consistent and superior chemical resistance, thermal stability, and electrical insulation, which are non-negotiable in critical industries like semiconductor manufacturing, medical devices, and food processing.

The choice between virgin and recycled PTFE is fundamentally a decision about risk management. Virgin PTFE is specified when the potential cost of contamination, material failure, or inconsistent performance far outweighs any savings from using a recycled grade.

The Foundation of Performance: Uncompromised Purity

The unique advantages of virgin PTFE all stem from a single, defining characteristic: its composition is 100% pure polymer. This eliminates the variables and potential contaminants inherent in reprocessed materials.

What "Virgin" Truly Means

Virgin PTFE is a polymer produced directly from its base raw materials. It is free from any reprocessed material, fillers, or additives.

This purity ensures that every batch exhibits the exact same properties, providing a level of reliability that recycled materials cannot match.

Unmatched Chemical Inertness

Because it contains no foreign materials, virgin PTFE offers extreme resistance to nearly all chemicals and solvents.

This makes it indispensable for seals, gaskets, and linings in pharmaceutical and aggressive chemical processing, where material degradation could lead to catastrophic failure.

Superior Electrical Insulation

The molecular purity of virgin PTFE results in exceptionally high dielectric strength, making it one of the best electrical insulators known.

This property is critical in precision electronics and semiconductor manufacturing, where it's used to insulate high-frequency cables and components, preventing signal loss or electrical shorts.

Guaranteed Safety and Biocompatibility

Virgin PTFE is FDA approved for contact with food, beverages, and pharmaceuticals.

Its inert and pure nature ensures that no harmful substances will leach into the product, a critical requirement for food processing equipment, medical devices, and cosmetic applications.

Understanding the Trade-offs: The Limits of Purity

While its purity is its greatest strength, it also leads to inherent weaknesses. Understanding these limitations is crucial for proper material selection.

The Problem of Creep (Cold Flow)

Virgin PTFE is a relatively soft material that is subject to creep, also known as cold flow.

This means that under sustained pressure, even at room temperature, the material can slowly deform and lose its original shape.

Consequences of Deformation

This tendency to creep can be a significant issue in mechanical applications. For gaskets or seals under high compressive loads, it can lead to a loss of surface pressure over time, resulting in leaks.

For this reason, pure virgin PTFE is often limited to applications with mild temperature and pressure conditions where structural integrity under load is not the primary concern.

When Purity Isn't Enough

For applications requiring greater mechanical strength, stiffness, or creep resistance, engineers turn to filled or modified PTFE.

By adding fillers like glass, carbon, or bronze, the mechanical properties are significantly enhanced, though this comes at the cost of the absolute purity and some of the chemical resistance of the virgin material.

Making the Right Choice for Your Application

Selecting the correct grade of PTFE requires a clear understanding of your project's most critical requirements.

- If your primary focus is safety and preventing contamination: Virgin PTFE is the only choice for medical, pharmaceutical, and food-grade applications due to its FDA approval and inertness.

- If your primary focus is high-performance electrical insulation: Virgin PTFE's unmatched dielectric strength makes it essential for high-frequency electronics and semiconductor equipment.

- If your primary focus is mechanical stability under load: A filled or modified grade of PTFE will provide the necessary creep resistance and stiffness that virgin PTFE lacks.

- If your primary focus is general-purpose use in a non-critical environment: Recycled PTFE can be a cost-effective and suitable alternative where absolute purity is not required.

Ultimately, choosing the right material is about aligning its specific properties with the precise demands and risks of your application.

Summary Table:

| Property | Virgin PTFE Advantage |

|---|---|

| Purity | 100% pure polymer, no reprocessed content |

| Chemical Resistance | Unmatched inertness to aggressive chemicals |

| Electrical Insulation | Superior dielectric strength |

| Biocompatibility | FDA approved for food, medical, and pharmaceutical use |

Need high-purity PTFE components you can trust?

For applications where contamination is not an option, KINTEK's precision-manufactured virgin PTFE components (seals, liners, labware) deliver the guaranteed purity and performance your industry demands. From prototypes to high-volume orders, we ensure reliability for the semiconductor, medical, and laboratory sectors.

Contact us today to discuss your specific requirements and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech