The primary advantage of Teflon's non-stick property is its ability to create a surface that releases materials with extreme ease. This unique characteristic prevents substances from adhering, which directly translates into simplified cleaning, reduced material waste, and more efficient mechanical operations.

While the "non-stick" quality is its most famous trait, its true value emerges from how this property works in concert with Teflon's high heat resistance, chemical inertness, and low friction to solve a vast range of industrial and consumer challenges.

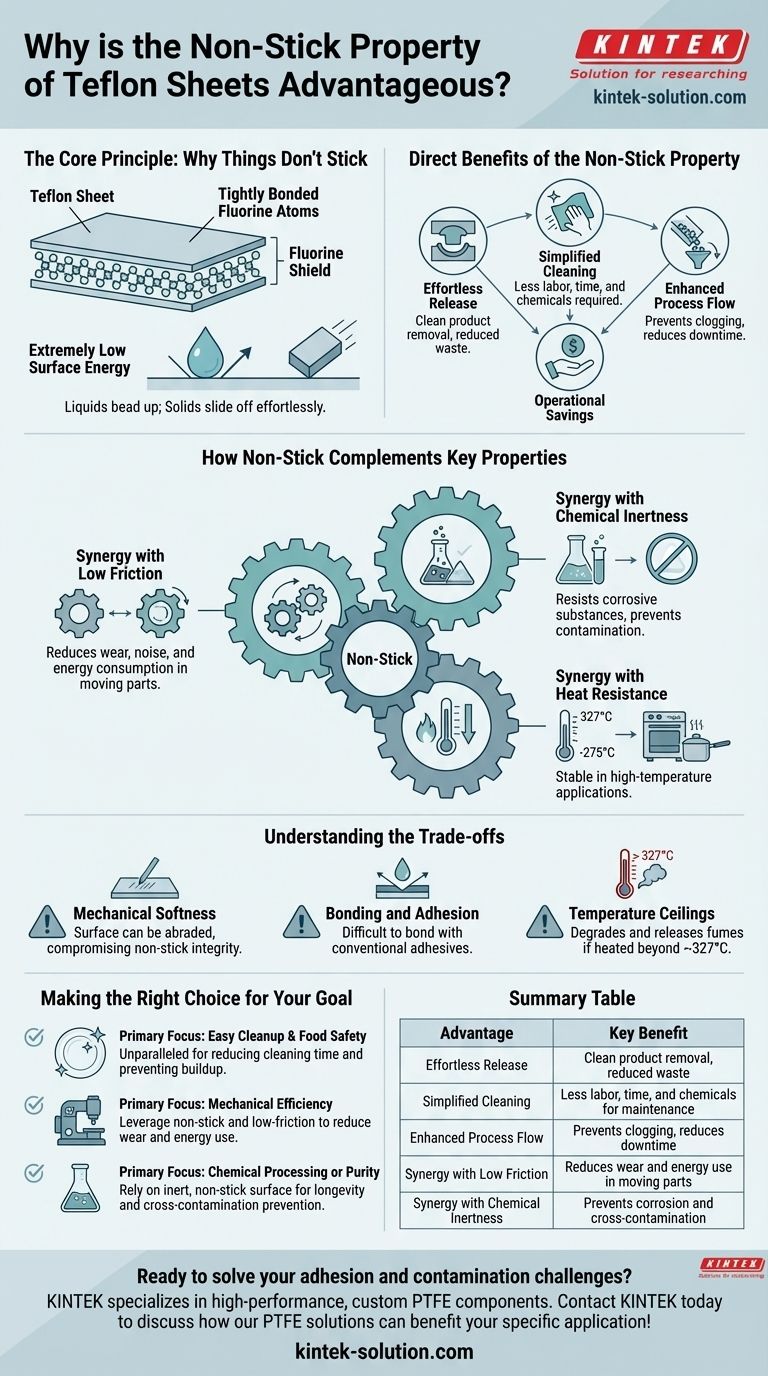

The Core Principle: Why Things Don't Stick

To understand its advantages, it's helpful to know why Teflon (PTFE) is non-stick at a molecular level. The entire surface is protected by a tightly bonded shield of fluorine atoms.

A Surface of Low Energy

This fluorine shield creates an exceptionally low surface energy. In practical terms, this means liquids bead up and solids have almost nothing to "grip" onto, causing them to slide off effortlessly.

Preventing Adhesion and Buildup

Because other materials are not chemically attracted to the Teflon surface, adhesion is minimized. This prevents the gradual buildup of residues, contaminants, or production materials that can plague other surfaces.

Direct Benefits of the Non-Stick Property

The inability of substances to adhere to Teflon sheets provides several immediate, high-impact advantages in both industrial and everyday applications.

Effortless Release of Materials

In applications like food processing or industrial molding, the non-stick surface ensures that products can be removed cleanly and completely. This reduces product waste and maintains the integrity of the finished item.

Simplified Cleaning and Maintenance

Surfaces that resist buildup are fundamentally easier and faster to clean. This quality dramatically reduces the labor, time, and harsh chemicals required for maintenance, leading to significant operational savings.

Enhanced Process Flow

In systems that transport materials, such as chutes or conveyor belts, a non-stick surface prevents clogging and ensures a smooth, consistent flow. This is critical for maintaining efficiency and preventing downtime.

How "Non-Stick" Complements Other Key Properties

The non-stick feature does not exist in a vacuum. Its power is amplified by Teflon's other inherent characteristics, making it a uniquely versatile material.

Synergy with Low Friction

The non-stick property is directly related to Teflon's extremely low coefficient of friction. While "non-stick" prevents adhesion, "low friction" allows objects to slide across the surface with minimal resistance. This combination is ideal for bearings, gears, and slide plates, where it reduces wear, noise, and energy consumption.

Synergy with Chemical Inertness

Teflon is resistant to nearly all chemicals. Its non-stick nature means corrosive or reactive substances not only fail to damage it but also slide off without leaving a residue, ensuring material purity and preventing cross-contamination.

Synergy with Heat Resistance

The non-stick surface remains stable across a wide temperature range (from -275°C up to 327°C). This allows it to be used in high-temperature applications like industrial ovens, heat exchangers, and cookware without losing its release properties.

Understanding the Trade-offs

No material is perfect. To use Teflon effectively, it's crucial to understand its limitations.

Mechanical Softness

Teflon is a relatively soft material. Its surface can be scratched or abraded by sharp or abrasive materials, which can compromise its non-stick integrity over time.

Bonding and Adhesion

The very property that makes Teflon non-stick also makes it difficult to bond to other materials using conventional adhesives. Special surface treatments are often required to make it stick to other substrates.

Temperature Ceilings

While its heat resistance is excellent, Teflon has a definitive upper limit. If heated beyond approximately 327°C (620°F), it can begin to degrade and release fumes.

Making the Right Choice for Your Goal

Ultimately, the advantage of Teflon's non-stick nature depends entirely on your specific application and objective.

- If your primary focus is easy cleanup and food safety: The non-stick surface provides an unparalleled advantage in reducing cleaning time and preventing material buildup.

- If your primary focus is mechanical efficiency: Leverage the combination of non-stick and low-friction properties to reduce wear, energy consumption, and part failure in moving components.

- If your primary focus is chemical processing or purity: Rely on the inert, non-stick surface to line vessels, pipes, and containers, ensuring both longevity and prevention of cross-contamination.

By understanding how Teflon's famous non-stick quality is part of a larger system of beneficial properties, you can apply it effectively to solve critical engineering and operational challenges.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Effortless Release | Clean product removal, reduced waste |

| Simplified Cleaning | Less labor, time, and chemicals for maintenance |

| Enhanced Process Flow | Prevents clogging, reduces downtime |

| Synergy with Low Friction | Reduces wear and energy use in moving parts |

| Synergy with Chemical Inertness | Prevents corrosion and cross-contamination |

Ready to solve your adhesion and contamination challenges?

KINTEK specializes in manufacturing high-performance, custom PTFE components like seals, liners, and labware. Our precision-engineered Teflon sheets leverage non-stick properties to help semiconductor, medical, laboratory, and industrial clients achieve superior process efficiency, reduce maintenance costs, and ensure product purity.

We offer custom fabrication from prototypes to high-volume orders. Contact KINTEK today to discuss how our PTFE solutions can benefit your specific application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments