The low-friction property of Teflon bushings is their defining operational advantage. This characteristic, technically known as a low coefficient of friction, is crucial because it allows moving parts to glide over one another with minimal resistance. This directly reduces wear and tear, minimizes the need for external lubrication, and improves the overall efficiency of mechanical systems.

The true importance of Teflon's low friction isn't just about making things slippery; it's about creating a self-sustaining, low-maintenance system that protects itself from wear, reduces operational costs, and simplifies mechanical design.

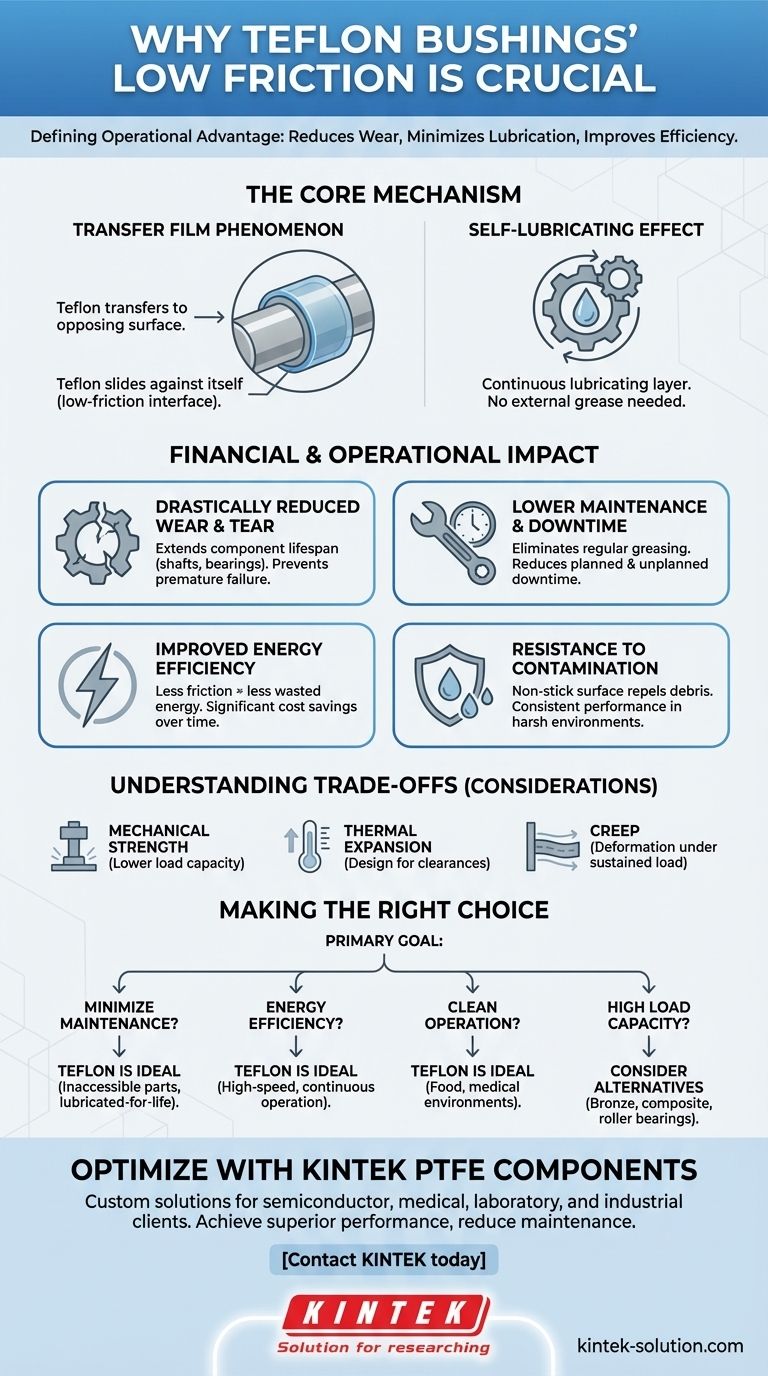

The Core Mechanism of Low Friction

At a microscopic level, Teflon's low friction is unique. It fundamentally changes how two surfaces interact, leading to a cascade of benefits that define its value in engineering.

The Transfer Film Phenomenon

When a part moves against a Teflon (PTFE) bushing, an incredibly thin layer of the Teflon material transfers onto the opposing surface.

This means the Teflon is no longer sliding against the metal shaft or housing. Instead, Teflon begins sliding against itself, which creates an exceptionally low-friction interface.

The Self-Lubricating Effect

This transfer film provides a continuous lubricating layer without the need for external grease or oil.

This "self-lubricating" property is inherent to the material. It allows components to operate smoothly from the very first movement and for the entire life of the bushing.

The Financial and Operational Impact

The physical property of low friction translates directly into significant, measurable advantages in cost, reliability, and performance.

Drastically Reduced Wear and Tear

Friction is the primary driver of mechanical wear. By minimizing it, Teflon bushings protect both themselves and the components they support.

This extends the operational lifespan of expensive parts like shafts and bearings, preventing premature failure.

Lower Maintenance and Downtime

Because Teflon bushings are self-lubricating, they eliminate the labor and material costs associated with regular greasing.

This is especially valuable for parts that are difficult to access. It reduces planned downtime for maintenance and prevents failures from missed lubrication cycles.

Improved Energy Efficiency

In any machine, energy is lost overcoming friction. Less friction means less wasted energy.

For high-speed or continuously running equipment, this reduction in energy consumption can lead to significant operational cost savings over time.

Resistance to Contamination

Teflon's non-stick nature prevents contaminants, chemicals, and other debris from adhering to its surface.

This ensures the low-friction interface remains clean and effective, maintaining consistent performance even in harsh environments.

Understanding the Trade-offs

While its low friction is a powerful advantage, Teflon (PTFE) is not the universal solution for every application. Its material properties introduce specific limitations that must be considered.

Mechanical Strength and Load

PTFE is a relatively soft material compared to metal. It has lower compressive strength and may not be suitable for applications with extremely high static or dynamic loads.

Thermal Expansion

Like most polymers, Teflon has a higher coefficient of thermal expansion than metals. In designs with very tight tolerances, temperature fluctuations can cause clearance issues that must be accounted for by the designer.

Creep and Deformation

Under a constant, sustained load, Teflon can slowly deform over time, a phenomenon known as "creep." This can be a limiting factor in precision applications where dimensional stability is critical.

Making the Right Choice for Your Goal

Selecting the right bushing material requires aligning its properties with your primary objective.

- If your primary focus is minimizing maintenance: Teflon is ideal for inaccessible components or creating "lubricated-for-life" systems where regular servicing is impractical.

- If your primary focus is energy efficiency: Use Teflon bushings in high-speed or continuously rotating applications to reduce parasitic energy loss from friction.

- If your primary focus is clean operation: Teflon's self-lubricating nature is perfect for environments where grease or oil contamination is unacceptable, such as food processing or medical devices.

- If your primary focus is high load capacity: A bronze, composite, or roller bearing may be a more appropriate choice, as Teflon's mechanical properties could be the limiting factor.

Ultimately, choosing a Teflon bushing is a strategic decision to prioritize long-term reliability and operational simplicity.

Summary Table:

| Benefit | Impact |

|---|---|

| Reduced Wear & Tear | Extends lifespan of components like shafts and bearings. |

| Lower Maintenance | Eliminates need for regular greasing, reducing downtime. |

| Energy Efficiency | Minimizes energy loss from friction, lowering operational costs. |

| Contamination Resistance | Non-stick surface ensures consistent performance in harsh environments. |

Optimize your mechanical systems with precision-engineered PTFE components from KINTEK.

Our expertise in custom fabricating Teflon seals, liners, bushings, and labware ensures you get a solution tailored to your specific needs—whether you require prototypes or high-volume orders. We help semiconductor, medical, laboratory, and industrial clients achieve superior performance through low-friction, self-lubricating designs that reduce maintenance and extend equipment life.

Contact KINTEK today to discuss how our PTFE components can enhance your application's reliability and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability