At its core, Teflon's exceptional status comes from a unique and powerful combination of properties that are rarely found together in a single material. Its value is rooted in its ability to be simultaneously non-stick, chemically inert, heat resistant, and an excellent electrical insulator, making it a "problem-solver" material across countless industries.

The true reason Teflon is so revered is not just one of its famous traits, but its capacity to deliver elite performance in chemical, thermal, and mechanical applications all at once. This versatility makes it an invaluable component in everything from household cookware to critical aerospace systems.

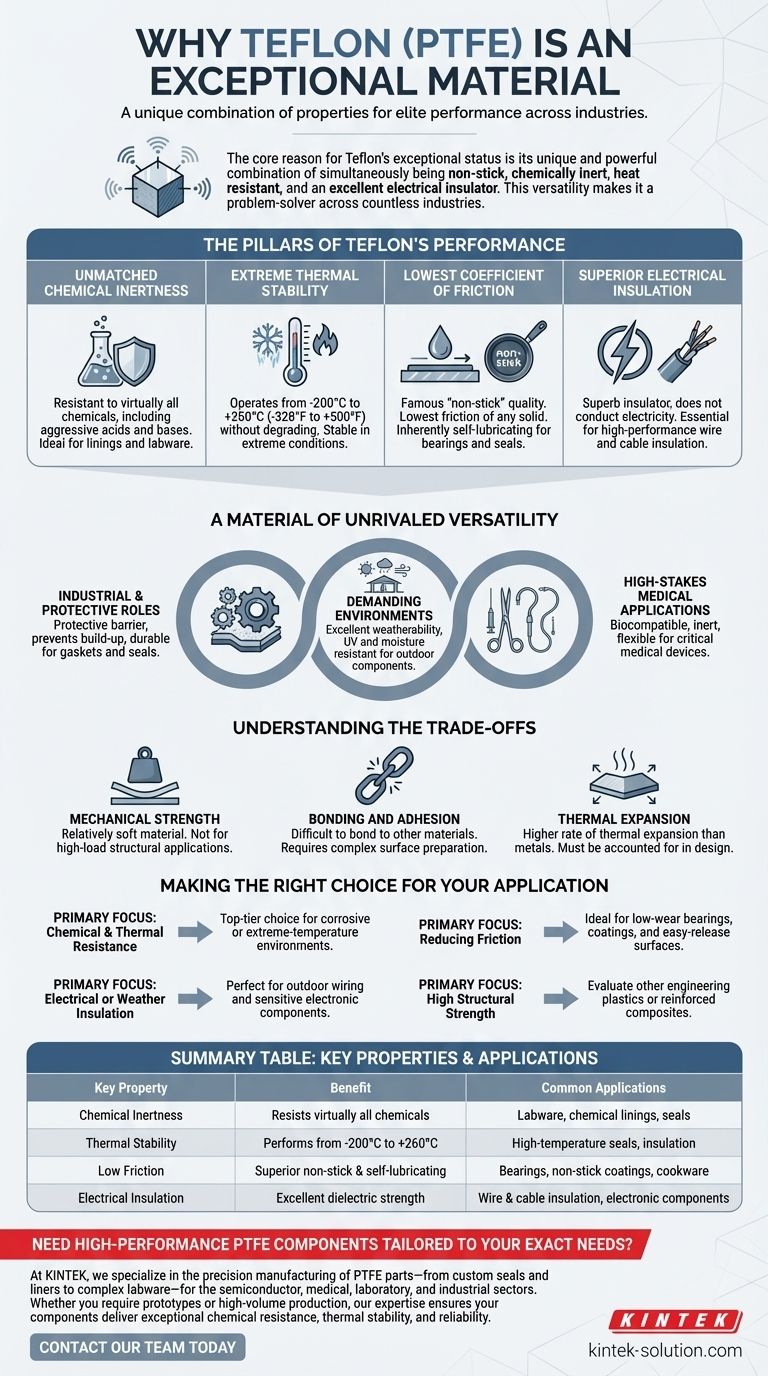

The Pillars of Teflon's Performance

To understand why Teflon (PTFE) is so widely adopted, we must look at the fundamental properties that define it. These characteristics work in concert to deliver unmatched reliability under demanding conditions.

Unmatched Chemical Inertness

Teflon is famously resistant to virtually all chemicals, including aggressive acids and bases. This makes it an ideal material for creating inert linings for laboratory appliances, storage tanks, and industrial pipework that handle corrosive substances.

Extreme Thermal Stability

The material demonstrates remarkable performance across a vast temperature spectrum. It remains stable and functional in conditions ranging from -200°C to +260°C (-328°F to +500°F) without degrading, a range that few other polymers can withstand.

The Lowest Coefficient of Friction

Known colloquially as its "non-stick" quality, Teflon has one of the lowest coefficients of friction of any known solid. This inherent lubricity is critical for creating anti-friction devices like bearings and seals, and it is the key property behind its use in non-stick cookware.

Superior Electrical Insulation

Teflon is a superb electrical insulator, meaning it does not conduct electricity. This property, combined with its heat resistance, makes it a premier choice for insulating high-performance wires and cables, especially in demanding automotive and aerospace applications.

A Material of Unrivaled Versatility

The combination of these core properties gives Teflon an incredibly broad range of applications. Its reliability in one area often complements its strengths in another, making it a versatile and dependable choice.

In Industrial and Protective Roles

As a sheet or coating, Teflon acts as a protective barrier. In manufacturing, it prevents scorching, ink smudging, and the buildup of adhesives on equipment, ensuring smooth and clean operations. Its durability makes it suitable for gaskets and seals that must withstand harsh conditions.

In Demanding Environments

Teflon exhibits excellent weatherability. It is highly resistant to degradation from UV light, moisture, and abrasion, making it perfect for outdoor components like architectural membranes, cable coatings, and external insulators that are exposed to the elements.

In High-Stakes Medical Applications

The material's inertness, flexibility, and consistency make it invaluable in the medical field. It is frequently used for critical components like catheters and surgical tubes that must be biocompatible and perform reliably without reacting with bodily fluids.

Understanding the Trade-offs

No material is perfect for every scenario. To make an informed decision, it's crucial to recognize Teflon's limitations.

Mechanical Strength

While durable in many ways, standard PTFE is a relatively soft material. It is not suited for high-load structural applications where hardness and rigidity are the primary requirements. Its strength is in lubricity and resistance, not in bearing heavy structural loads.

Bonding and Adhesion

The very non-stick property that makes Teflon valuable also makes it difficult to bond to other materials. Attaching Teflon to a substrate often requires complex and costly surface preparation techniques, like chemical etching, to create a viable bond.

Thermal Expansion

Teflon has a higher rate of thermal expansion compared to metals. In applications with significant temperature fluctuations, this difference must be accounted for in the design to prevent stress and failure, especially when it is part of a composite assembly.

Making the Right Choice for Your Application

Selecting a material requires aligning its properties with your primary goal. Teflon should be considered a specialist material for specific challenges.

- If your primary focus is chemical and thermal resistance: Teflon is a top-tier choice for linings, seals, and components in corrosive or extreme-temperature environments.

- If your primary focus is reducing friction: Its self-lubricating, non-stick surface makes it ideal for creating low-wear bearings, low-friction coatings, and easy-release surfaces.

- If your primary focus is electrical or weather insulation: Its combination of dielectric strength and UV resistance is perfect for protecting outdoor wiring and sensitive electronic components.

- If your primary focus is high structural strength: You should evaluate other engineering plastics or reinforced Teflon composites, as its softness is a key limitation for load-bearing parts.

Ultimately, Teflon’s value is derived from its ability to solve multiple complex engineering challenges with a single, highly reliable material.

Summary Table:

| Key Property | Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists virtually all chemicals | Labware, chemical linings, seals |

| Thermal Stability | Performs from -200°C to +260°C | High-temperature seals, insulation |

| Low Friction | Superior non-stick & self-lubricating | Bearings, non-stick coatings, cookware |

| Electrical Insulation | Excellent dielectric strength | Wire & cable insulation, electronic components |

Need high-performance PTFE components tailored to your exact needs?

At KINTEK, we specialize in the precision manufacturing of PTFE parts—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures your components deliver exceptional chemical resistance, thermal stability, and reliability.

Contact our team today to discuss your project and discover how our custom PTFE solutions can solve your most demanding application challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions