In short, Teflon's price is a direct reflection of its exceptional and unique combination of material properties. Unlike common commodity plastics, it is engineered to perform reliably under extreme conditions where other materials would fail, boasting superior chemical resistance, thermal stability, and an extremely low-friction surface.

You are not just paying for a plastic; you are paying for a specialized solution to a difficult engineering problem. The cost of Teflon (PTFE) is justified when its unique performance characteristics are not just desirable, but mission-critical for the application.

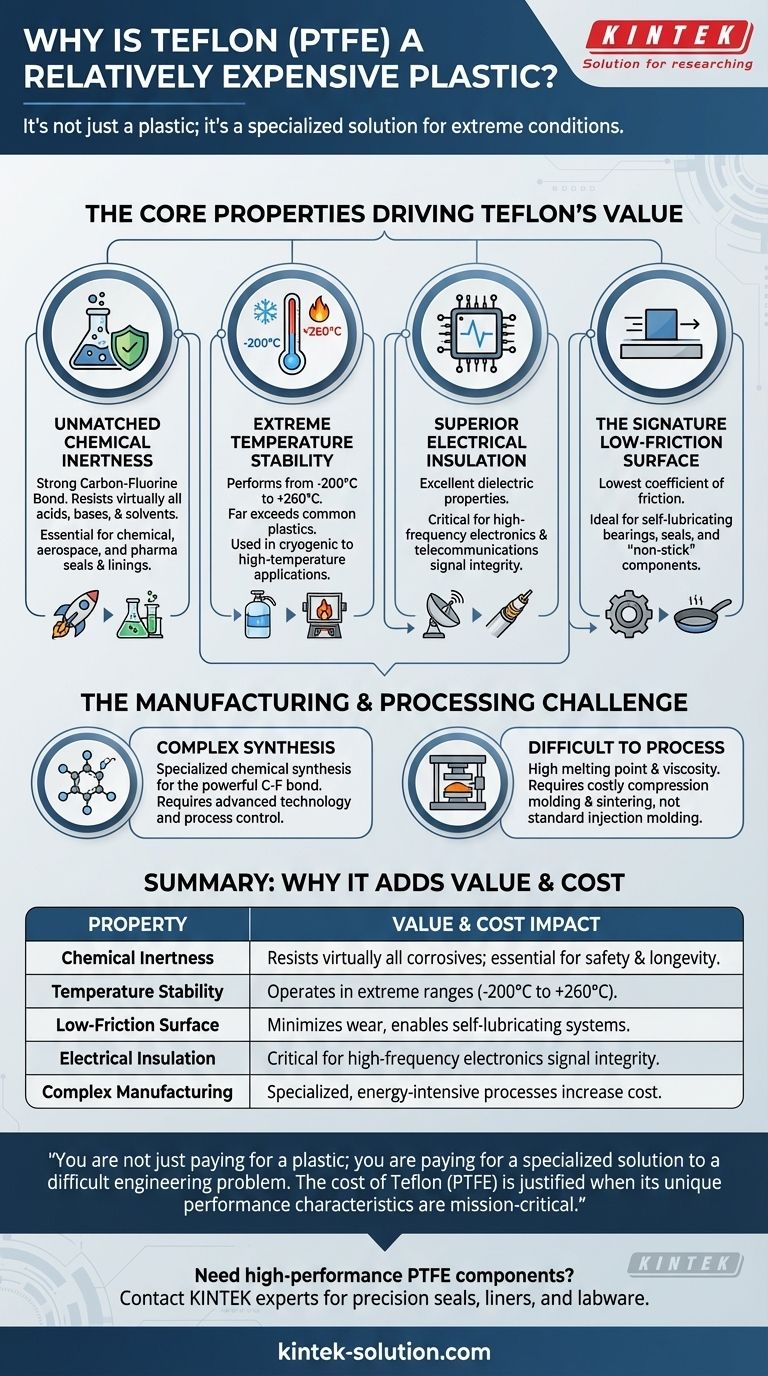

The Core Properties Driving Teflon's Value

Teflon, the brand name for Polytetrafluoroethylene (PTFE), belongs to a class of materials called fluoropolymers. Its high cost stems from a set of properties that are difficult and expensive to replicate in a single material.

Unmatched Chemical Inertness

The bond between carbon and fluorine atoms in PTFE is exceptionally strong. This chemical structure makes it almost completely inert.

It will not react with the vast majority of corrosive acids, bases, and solvents. This makes it an essential material for seals, gaskets, and linings in the chemical processing, aerospace, and pharmaceutical industries where material failure is not an option.

Extreme Temperature Stability

Teflon can withstand a very wide range of temperatures, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability allows it to be used in applications from cryogenic equipment to high-temperature industrial processes, a range far exceeding that of plastics like polyethylene or PVC.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very low dielectric constant, even at high frequencies.

This property is critical for manufacturing high-performance coaxial cables, connectors, and printed circuit boards used in telecommunications and radar systems, where signal integrity is paramount.

The Signature Low-Friction Surface

Teflon has one of the lowest coefficients of friction of any known solid material, giving it its famous "non-stick" quality.

While well-known in cookware, this property is vital for industrial applications like self-lubricating bearings, seals, and other components where minimizing friction and wear is crucial for efficiency and longevity.

The Manufacturing and Processing Challenge

The properties that make Teflon so high-performing also make it significantly more difficult and energy-intensive to produce and form into finished parts compared to common plastics.

Complex Synthesis

Creating the powerful carbon-fluorine bond that gives Teflon its stability is a complex and specialized chemical synthesis process. This requires more advanced technology and process control than the production of simpler commodity polymers.

Difficult to Process

PTFE has an extremely high melting point and viscosity, meaning it doesn't flow like a typical thermoplastic. It cannot be easily processed using standard, high-speed methods like injection molding.

Instead, it often requires slower, more costly techniques like compression molding and sintering (a process of compacting and heating a powder), which adds significant cost to the final product.

Understanding the Trade-offs: When Teflon is Overkill

While its performance is impressive, Teflon is not the right choice for every situation. Its high cost necessitates a clear understanding of its limitations.

Cost vs. Performance

For applications that do not involve extreme temperatures, harsh chemicals, or high-frequency electrical signals, Teflon is often an unnecessary expense. A commodity plastic like polypropylene can provide adequate performance for a fraction of the price.

Mechanical Limitations

Standard PTFE is relatively soft and has poor resistance to wear and creep (the tendency to deform under constant load). While it can be reinforced with fillers like glass or carbon to improve these properties, this adds further complexity and cost.

Making the Right Choice for Your Goal

Selecting a material requires balancing performance needs with budget constraints. Teflon's value is realized when its specific strengths align with the application's demands.

- If your primary focus is surviving extreme chemicals or temperatures: Teflon is often non-negotiable, and its cost is justified by preventing catastrophic failure and ensuring operational safety.

- If your primary focus is electrical insulation for high-frequency systems: The low dielectric constant of Teflon is a critical performance driver that cheaper materials simply cannot match.

- If your primary focus is a low-cost, general-purpose component: A commodity plastic like polyethylene or nylon will almost always be the more practical and economical choice.

Ultimately, Teflon's price is a function of its role as a high-performance specialty material, engineered for problems that commodity plastics cannot solve.

Summary Table:

| Property | Why It Adds Value & Cost |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; essential for safety in chemical, pharma, and aerospace. |

| Temperature Stability | Performs from -200°C to +260°C, far beyond most plastics, enabling use in extreme environments. |

| Low-Friction Surface | Lowest coefficient of friction, ideal for non-stick and self-lubricating components. |

| Electrical Insulation | Excellent dielectric properties, critical for high-frequency electronics and telecommunications. |

| Complex Manufacturing | Requires specialized, energy-intensive processes like sintering, not standard injection molding. |

Need high-performance PTFE components that justify their cost?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our custom fabrication—from prototypes to high-volume orders—ensures you get the exact Teflon solution your mission-critical application demands.

Contact our experts today to discuss how our PTFE components can solve your toughest engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials