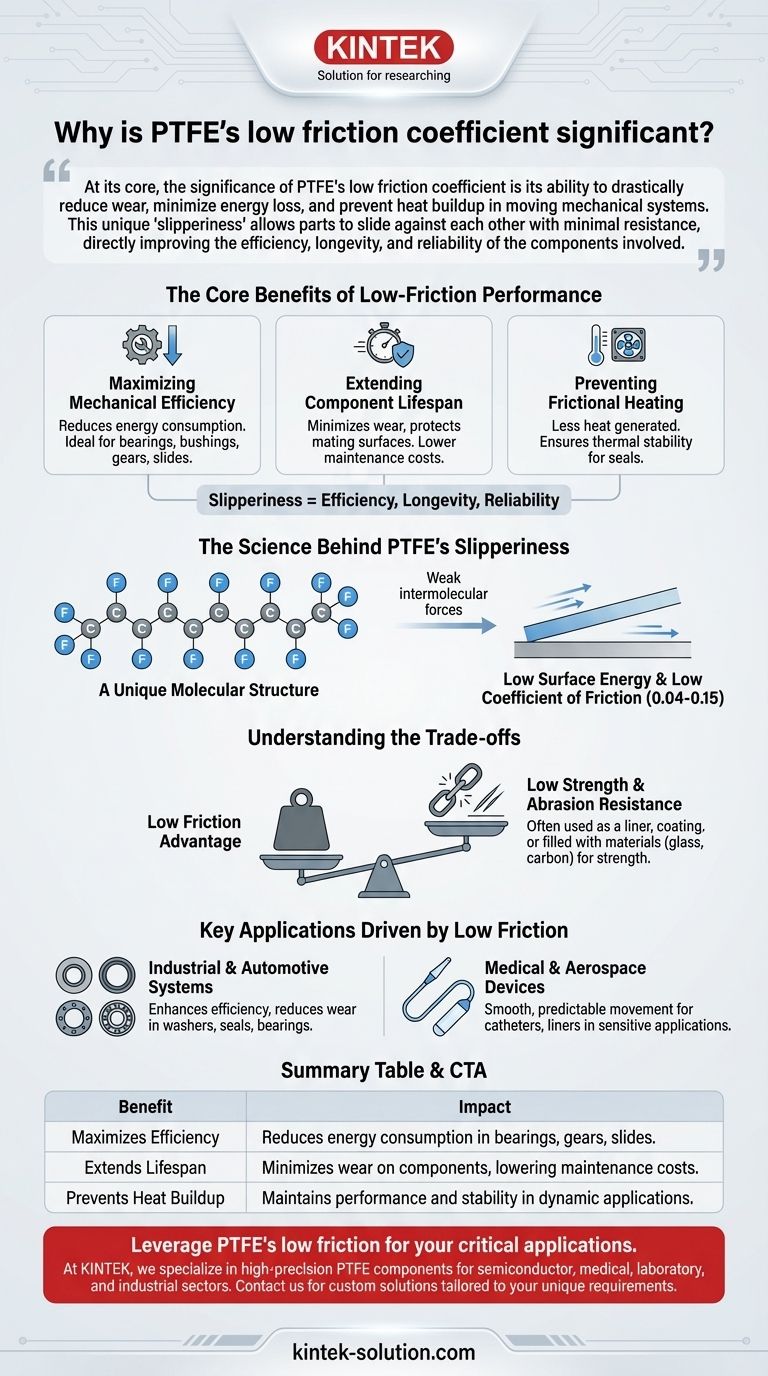

At its core, the significance of PTFE's low friction coefficient is its ability to drastically reduce wear, minimize energy loss, and prevent heat buildup in moving mechanical systems. This unique "slipperiness" allows parts to slide against each other with minimal resistance, directly improving the efficiency, longevity, and reliability of the components involved.

The true value of PTFE's low friction is not just the property itself, but how it fundamentally solves the universal engineering challenges of wear and energy waste. It enables the design of highly efficient and durable systems where smooth, reliable motion is non-negotiable.

The Core Benefits of Low-Friction Performance

The coefficient of friction for PTFE, typically between 0.04 and 0.15, is one of the lowest of any solid material. This property translates into several tangible engineering advantages.

Maximizing Mechanical Efficiency

When components move against each other, friction creates resistance that consumes energy. PTFE’s low friction minimizes this resistance.

This translates directly into reduced energy consumption for the system to operate, making it ideal for applications like bearings, bushings, gears, and slides. Smooth, effortless movement is the primary goal.

Extending Component Lifespan

Friction is a direct cause of wear and tear. Over time, it degrades the surfaces of moving parts, leading to failure.

By minimizing this force, PTFE not only extends its own lifespan but also protects the mating surfaces it comes into contact with. This leads to significantly lower maintenance costs and longer operational life for the entire assembly.

Preventing Frictional Heating

A direct byproduct of friction is heat. In dynamic applications, especially high-speed ones, this heat can cause materials to degrade, warp, or fail.

PTFE's low friction means less heat is generated during operation. This thermal stability is critical for the integrity of seals and other components that must maintain their shape and properties under stress.

The Science Behind PTFE's Slipperiness

The reason for PTFE's uniquely low friction lies in its molecular structure.

A Unique Molecular Structure

PTFE is composed of long chains of carbon atoms completely surrounded by fluorine atoms. This creates a highly symmetrical, electrically neutral molecule.

The dipole moments of these symmetrical structures effectively cancel each other out. This results in very weak forces of attraction between PTFE molecules and other surfaces, manifesting as low surface energy and a low coefficient of friction.

Understanding the Trade-offs

While its low friction is a massive advantage, it is a direct result of its molecular makeup, which also introduces limitations.

Low Strength and Abrasion Resistance

The same weak intermolecular forces that give PTFE its slipperiness also result in lower tensile strength and poor abrasion resistance compared to other engineering plastics.

This means PTFE is not suitable for high-load or high-wear applications on its own. It is often used as a liner or coating, or filled with other materials like glass or carbon to improve its mechanical properties.

Key Applications Driven by Low Friction

PTFE's unique properties make it the material of choice in several critical fields.

Industrial and Automotive Systems

In manufacturing and automotive industries, PTFE is essential for washers, seals, and bearings. It enhances machinery efficiency by ensuring parts move smoothly, reducing wear and extending the time between maintenance cycles.

Medical and Aerospace Devices

In sensitive applications, smooth and predictable movement is paramount. Medical-grade PTFE liners are used in devices like catheters to allow them to navigate through the body with minimal resistance, improving patient comfort and procedural success.

Making the Right Choice for Your Application

Selecting a material requires balancing its strengths against the demands of the environment.

- If your primary focus is energy efficiency and smooth operation: PTFE is an excellent choice for bearings, slides, and other components in low-load mechanical systems.

- If your primary focus is protecting mating surfaces and reducing maintenance: Its use in seals and washers prevents damage to more expensive metal parts, ensuring long-term reliability.

- If your primary focus is performance in sensitive environments: The biocompatibility and low friction of medical-grade PTFE make it indispensable for advanced medical devices.

Ultimately, PTFE's low friction coefficient makes it a cornerstone material for solving the fundamental engineering challenges of motion, wear, and efficiency.

Summary Table:

| Benefit | Impact |

|---|---|

| Maximizes Efficiency | Reduces energy consumption in bearings, gears, and slides. |

| Extends Lifespan | Minimizes wear on components, lowering maintenance costs. |

| Prevents Heat Buildup | Maintains performance and stability in dynamic applications. |

Leverage PTFE's low friction for your critical applications.

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems achieve maximum efficiency, extended lifespan, and reliable performance, even in demanding environments.

Whether you need prototypes or high-volume orders, we deliver solutions tailored to your unique requirements. Contact us today to discuss how our PTFE expertise can benefit your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance