In short, Polytetrafluoroethylene (PTFE) is used extensively in chemical processing because it is one of the most chemically inert and temperature-resistant polymers available. Its unique molecular structure allows it to withstand attack from highly corrosive acids, bases, and solvents that would rapidly degrade other materials, making it indispensable for ensuring safety and reliability in harsh industrial environments.

The core challenge in chemical processing is material containment. Aggressive substances at high temperatures create a constant risk of corrosion, leaks, and failure. PTFE solves this by providing a nearly universal barrier, protecting equipment, preventing contamination, and ensuring operational integrity where other materials cannot.

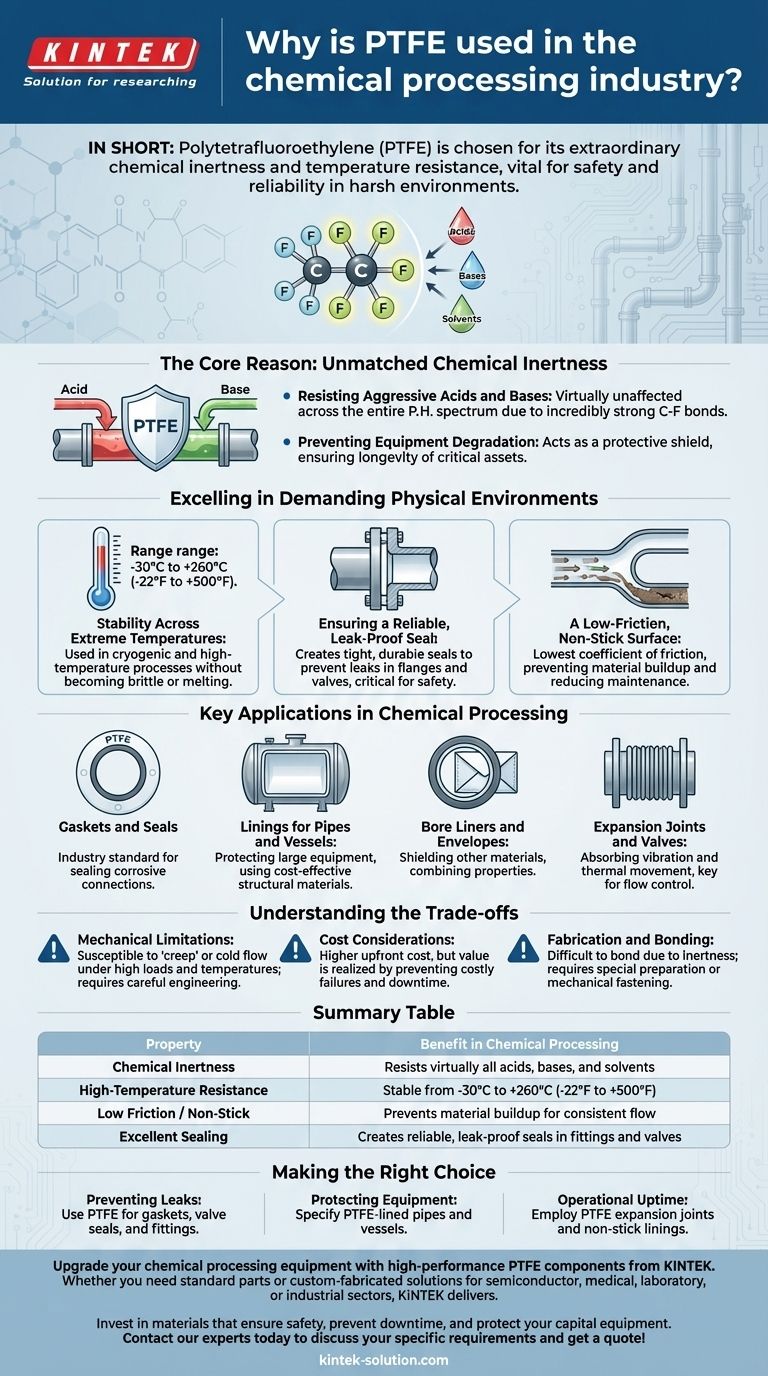

The Core Reason: Unmatched Chemical Inertness

The primary driver for PTFE adoption is its extraordinary resistance to chemical attack. This isn't just a minor advantage; it's a fundamental property that sets it apart.

Resisting Aggressive Acids and Bases

PTFE is virtually unaffected by even the most aggressive chemicals, including strong acids and caustic blends. Its stability across the entire P.H. spectrum is due to the incredibly strong carbon-fluorine bonds that make up its molecular backbone.

These bonds are extremely difficult to break, rendering the material inert when exposed to substances that would corrode metals and dissolve other plastics.

Preventing Equipment Degradation

By using PTFE, chemical plants can ensure the longevity and durability of their most critical assets. It acts as a protective shield, preventing the underlying structural materials of pipes, valves, and vessels from coming into contact with corrosive process fluids.

Excelling in Demanding Physical Environments

Beyond its chemical resilience, PTFE performs reliably under the physical stresses common in chemical plants.

Stability Across Extreme Temperatures

PTFE maintains its integrity over a remarkably wide operating temperature range, typically cited from -30°C up to +260°C (-22°F to +500°F).

This allows it to be used in processes involving both cryogenic fluids and high-temperature reactions without becoming brittle or melting.

Ensuring a Reliable, Leak-Proof Seal

As a mechanically stable and conformable material, PTFE is ideal for creating tight, durable seals. It prevents leaks in flanges, fittings, and valves, which is critical for safety, environmental protection, and process efficiency.

A Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This non-adhesive property is beneficial in preventing material buildup within processing equipment, ensuring consistent flow and reducing maintenance.

Key Applications in Chemical Processing

The properties of PTFE translate directly into its use in several critical components throughout a chemical facility.

Gaskets and Seals

PTFE gaskets are the industry standard for sealing connections in piping systems that handle corrosive chemicals. They provide a reliable seal that prevents dangerous leaks and protects the integrity of the process.

Linings for Pipes and Vessels

To protect large, expensive equipment like tanks and reactors from corrosion, a thin liner of PTFE is often applied to the interior surfaces. This provides complete chemical resistance while using a stronger, more cost-effective material like steel for structural support.

Bore Liners and Envelopes

In some applications, a PTFE "envelope" is used to shield a different type of gasket material from chemical attack. This combines the superior chemical resistance of PTFE with the mechanical properties of another material.

Expansion Joints and Valves

PTFE is used to manufacture flexible expansion joints that absorb vibration and thermal movement in piping systems. It is also a key material for valve seats and seals, ensuring reliable flow control for aggressive media.

Understanding the Trade-offs

While exceptionally capable, PTFE is not without its limitations. Acknowledging them is key to proper application.

Mechanical Limitations

PTFE is a relatively soft material and can be susceptible to "creep" or cold flow, especially under high mechanical loads and elevated temperatures. This requires careful engineering and design considerations, particularly for high-pressure gasket applications.

Cost Considerations

While it offers an excellent price-to-performance ratio over its lifespan, the upfront cost of PTFE components can be higher than that of less-capable materials. Its value is realized by preventing costly failures, downtime, and maintenance.

Fabrication and Bonding

PTFE's inertness and low-friction surface make it famously difficult to bond to other materials. Special surface preparation techniques or mechanical fastening methods are required for successful implementation in composite structures.

Making the Right Choice for Your System

Selecting PTFE is a decision based on prioritizing safety and long-term reliability in chemically aggressive environments.

- If your primary focus is preventing catastrophic leaks: Use PTFE for gaskets, valve seals, and fittings in any line carrying corrosive or high-purity chemicals.

- If your primary focus is protecting capital equipment: Specify PTFE-lined pipes, vessels, and transportation containers to shield structural steel from corrosion.

- If your primary focus is operational uptime: Employ PTFE expansion joints and non-stick linings to reduce maintenance cycles caused by material failure or buildup.

Ultimately, specifying PTFE is an investment in creating a safer, more durable, and more efficient chemical processing system.

Summary Table:

| Property | Benefit in Chemical Processing |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents |

| High-Temperature Resistance | Stable from -30°C to +260°C (-22°F to +500°F) |

| Low Friction / Non-Stick | Prevents material buildup for consistent flow |

| Excellent Sealing | Creates reliable, leak-proof seals in fittings and valves |

Upgrade your chemical processing equipment with high-performance PTFE components from KINTEK.

Whether you need standard parts or custom-fabricated solutions for demanding applications in the semiconductor, medical, laboratory, or industrial sectors, KINTEK delivers. We specialize in manufacturing precision PTFE seals, liners, labware, and more, from prototypes to high-volume orders.

Invest in materials that ensure safety, prevent downtime, and protect your capital equipment. Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications