The fundamental reason PTFE is used in medical applications is its unique combination of biological inertness, chemical resistance, and an extremely low-friction surface. This trio of properties means it does not react with human tissue, can withstand harsh sterilization processes, and allows medical devices to move smoothly and resist bacterial adhesion, making it exceptionally safe and effective for use in and on the human body.

The core value of Polytetrafluoroethylene (PTFE) in medicine is not just one of its properties, but the synergy between them. It simultaneously solves the critical challenges of material rejection by the body, chemical degradation of the device, and friction-related complications during medical procedures.

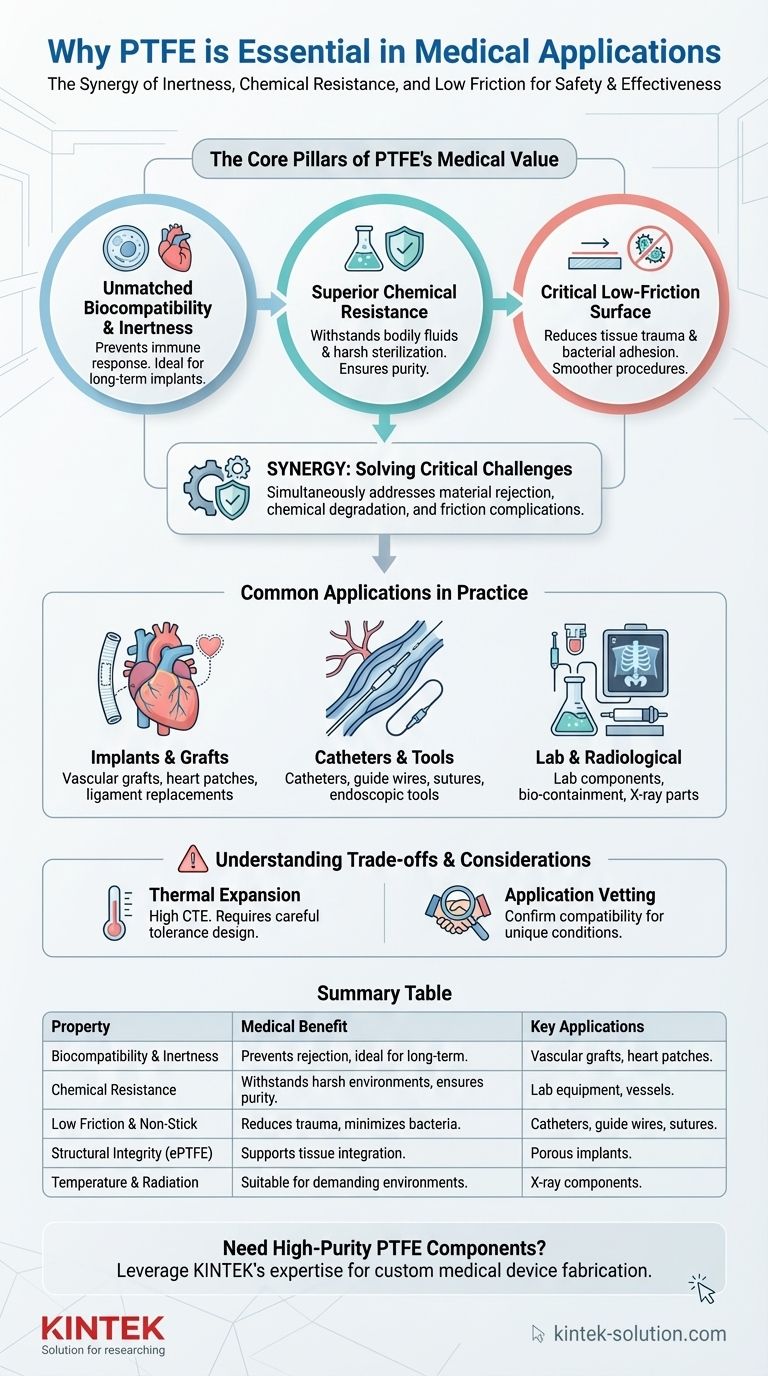

The Core Pillars of PTFE's Medical Value

To understand PTFE's role, it's essential to break down its primary characteristics and how they translate directly to medical benefits. Each property addresses a specific, high-stakes requirement in healthcare.

Unmatched Biocompatibility and Inertness

Biocompatibility means a material does not produce a toxic or immunological response when exposed to the body. PTFE is one of the most inert materials known.

It does not react with bodily fluids or tissue, which prevents adverse reactions and makes it ideal for long-term implants. This is why it's a trusted material for cardiovascular grafts, heart patches, and ligament replacements.

Superior Chemical Resistance

Medical devices must withstand aggressive substances, from bodily fluids to harsh sterilization chemicals. PTFE is resistant to nearly all chemicals.

This durability ensures the material's purity and structural integrity will not be compromised over the device's lifespan. This makes it suitable for bio-containment vessels, laboratory equipment components, and other tools that require repeated, rigorous cleaning.

The Critical Role of Low Friction

PTFE has one of the lowest coefficients of friction of any solid, creating an exceptionally non-stick and slippery surface.

This property is vital for devices like catheters, which can be inserted with less discomfort and tissue trauma. Crucially, this non-adhesive surface also reduces the ability of bacteria to form biofilms, helping to lower the risk of hospital-acquired infections.

Excellent Physical and Structural Integrity

Beyond its core traits, PTFE offers other valuable physical properties. It can be manufactured into a porous structure (ePTFE), which supports natural cell growth and integration for grafts and patches.

It also demonstrates high resistance to temperature and radiation, making it suitable for components in radiological equipment like X-ray machines.

Common Applications in Practice

The theoretical benefits of PTFE translate into a wide range of life-saving and performance-enhancing medical products.

Implants and Grafts

Due to its inert nature and porous potential, PTFE is used to manufacture vascular grafts and patches for repairing or replacing damaged tissue in the heart and blood vessels.

Catheters and Surgical Tools

The low-friction surface is essential for catheters, guide wires, and endoscopic instruments. It is also used in sutures, where its smooth passage through tissue minimizes damage.

Laboratory and Radiological Equipment

Its chemical resistance and purity make it a go-to material for laboratory equipment components that handle sensitive biological samples. Its radiation resistance is valuable for shielding components in diagnostic machinery.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. An expert understanding requires acknowledging its limitations.

The Importance of Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. This means its dimensions can change with temperature fluctuations, a factor that engineers must account for when designing components with very tight tolerances.

The Need for Application-Specific Vetting

Despite its broad chemical resistance, its compatibility for highly specialized uses must be confirmed. For devices exposed to unique chemical cocktails or extreme conditions, consulting with the manufacturer is a critical step to ensure safety and performance.

Making the Right Choice for Your Goal

To leverage PTFE effectively, you must align its properties with your primary application goal.

- If your primary focus is patient safety in implants: PTFE's biological inertness and ability to be structured for cellular integration make it a leading choice for grafts and patches.

- If your primary focus is procedural efficiency and infection control: The exceptionally low-friction, non-adhesive surface of PTFE is critical for devices like catheters and guide wires.

- If your primary focus is device longevity and purity: PTFE's resistance to harsh chemicals and sterilization methods ensures the integrity of laboratory equipment and containment systems.

Ultimately, PTFE's multifaceted performance profile makes it an indispensable material for advancing modern medical technology and improving patient outcomes.

Summary Table:

| Property | Medical Benefit | Key Applications |

|---|---|---|

| Biocompatibility & Inertness | Prevents rejection by the body, ideal for long-term implants. | Vascular grafts, heart patches, ligament replacements. |

| Chemical Resistance | Withstands harsh sterilization and bodily fluids, ensuring device purity. | Laboratory equipment, bio-containment vessels. |

| Low Friction & Non-Stick | Reduces tissue trauma during insertion and minimizes bacterial adhesion. | Catheters, guide wires, sutures, endoscopic tools. |

| Structural Integrity (ePTFE) | Supports natural tissue integration and growth. | Porous implants and grafts. |

| Temperature & Radiation Resistance | Suitable for components in demanding environments like radiology. | X-ray machine components, diagnostic equipment. |

Need High-Purity PTFE Components for Your Medical Device?

Leverage KINTEK's expertise in precision PTFE manufacturing for the semiconductor, medical, and laboratory industries. We specialize in custom fabrication—from prototypes to high-volume orders—ensuring your devices meet the highest standards of safety and performance.

Contact KINTEK today to discuss how our PTFE seals, liners, labware, and custom components can enhance your medical application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability