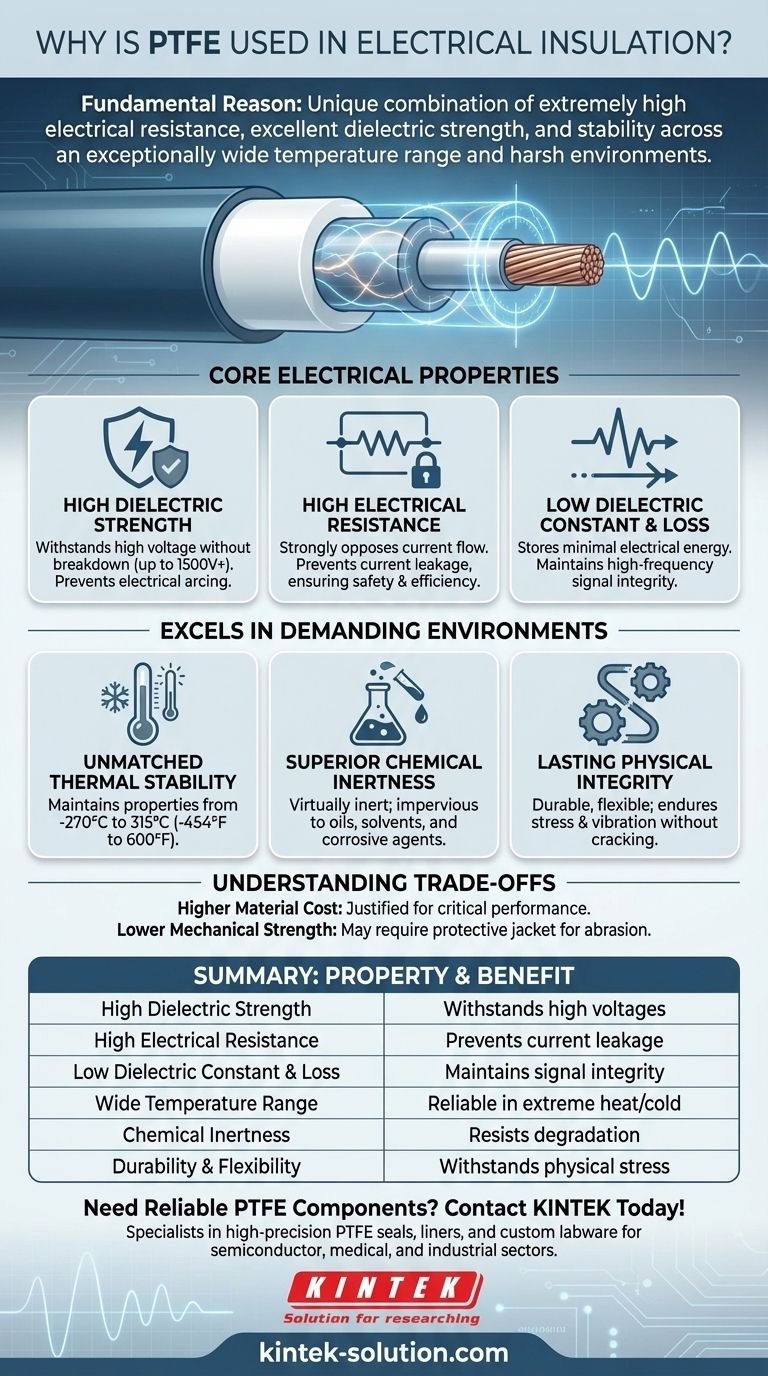

The fundamental reason PTFE is used for electrical insulation is its rare combination of extremely high electrical resistance, excellent dielectric strength, and the ability to maintain these properties across an exceptionally wide range of temperatures and harsh chemical environments. This makes it a uniquely reliable material for protecting critical components where failure is not an option.

While many materials can block electrical current, PTFE is chosen for critical applications because it performs reliably under conditions—extreme heat, corrosive chemicals, and high frequencies—that would cause lesser insulators to fail.

The Core Electrical Properties of PTFE

To understand PTFE's role, we must first look at its fundamental electrical characteristics. These properties are not just good; they are exceptional and work together to provide comprehensive electrical protection.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand high voltage without breaking down and allowing current to pass through.

PTFE possesses a very high dielectric strength. This allows it to insulate components carrying significant voltage—in some cases up to 1500 volts or more—without the risk of electrical arcing or leakage.

High Electrical Resistance

Electrical resistance is a measure of how strongly a material opposes the flow of electric current.

As an excellent insulator, PTFE has a very high electrical resistance. This property is essential for preventing current from leaking out of a conductor, which ensures both safety and the efficient operation of the device.

Low Dielectric Constant and Loss

For high-frequency applications, such as in data cables or advanced electronics, the dielectric constant and loss factor are critical.

PTFE has a very low dielectric constant, which means it stores very little electrical energy. This, combined with low electrical loss, ensures that the integrity of high-frequency signals is maintained as they pass through the cable, preventing signal degradation.

Why PTFE Excels in Demanding Environments

The true value of PTFE becomes clear when its electrical properties are considered alongside its remarkable physical and chemical resilience. It doesn't just insulate; it insulates reliably under extreme stress.

Unmatched Thermal Stability

Many insulators lose their effectiveness at high or low temperatures.

PTFE maintains its insulating properties and physical flexibility across a vast temperature range, from approximately -454°F to 600°F (-270°C to 315°C). This consistency makes it indispensable in aerospace, industrial, and military applications.

Superior Chemical Inertness

Electrical components are often exposed to oils, solvents, fuels, or other corrosive agents.

PTFE is virtually inert and impervious to almost all common solvents and chemicals. This ensures the insulation will not degrade or break down when exposed to harsh substances, guaranteeing long-term protection.

Lasting Physical Integrity

The strong carbon-fluorine bonds in PTFE's molecular structure give it significant flexibility.

This allows PTFE insulation, used in wires or as gaskets, to endure physical stress and vibration without cracking or failing. This durability is critical for ensuring the long-lasting protection of the electrical components it encases.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's performance is exceptional, it's important to recognize its limitations to make an informed decision.

Higher Material Cost

The primary drawback of PTFE is its cost.

It is significantly more expensive than common insulators like PVC or Polyethylene. Its use is typically justified only when its unique performance characteristics are a strict requirement.

Lower Mechanical Strength

PTFE is a relatively soft material with low resistance to abrasion and cutting.

In applications where the insulation will be subjected to significant physical wear and tear, it may require an additional protective jacket made from a more mechanically robust material.

Making the Right Choice for Your Application

Selecting the right insulator depends entirely on the operational demands of your project.

- If your primary focus is high-frequency signal integrity: PTFE is the industry standard due to its low dielectric constant and loss factor.

- If your application involves extreme temperatures or chemical exposure: PTFE's thermal stability and chemical inertness make it one of the few viable choices.

- If you need a general-purpose insulator for a stable, low-cost environment: A more common material like PVC is likely a more practical and cost-effective solution.

Ultimately, PTFE is the definitive choice when you require unwavering insulating performance in an environment that pushes materials to their limits.

Summary Table:

| Property | Benefit |

|---|---|

| High Dielectric Strength | Withstands high voltages without breakdown |

| High Electrical Resistance | Prevents current leakage for safety and efficiency |

| Low Dielectric Constant & Loss | Maintains signal integrity in high-frequency applications |

| Wide Temperature Range (-270°C to 315°C) | Performs reliably in extreme heat and cold |

| Chemical Inertness | Resists degradation from oils, solvents, and corrosive agents |

| Durability & Flexibility | Withstands physical stress and vibration without cracking |

Need reliable PTFE components for your critical electrical insulation challenges?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures your insulation solutions perform flawlessly under extreme conditions, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE expertise can enhance your application's safety and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials