At its core, PTFE is exceptionally well-suited for mechanisms that rotate or slide because it has the lowest coefficient of friction of any known solid material. This inherent slipperiness, combined with self-lubricating properties, allows parts to move against each other with minimal resistance and without the need for external oils or greases.

While PTFE is famous for being "non-stick," its true value in mechanical systems comes from a powerful combination of predictable, low-friction performance and extreme durability, which simplifies design and eliminates maintenance.

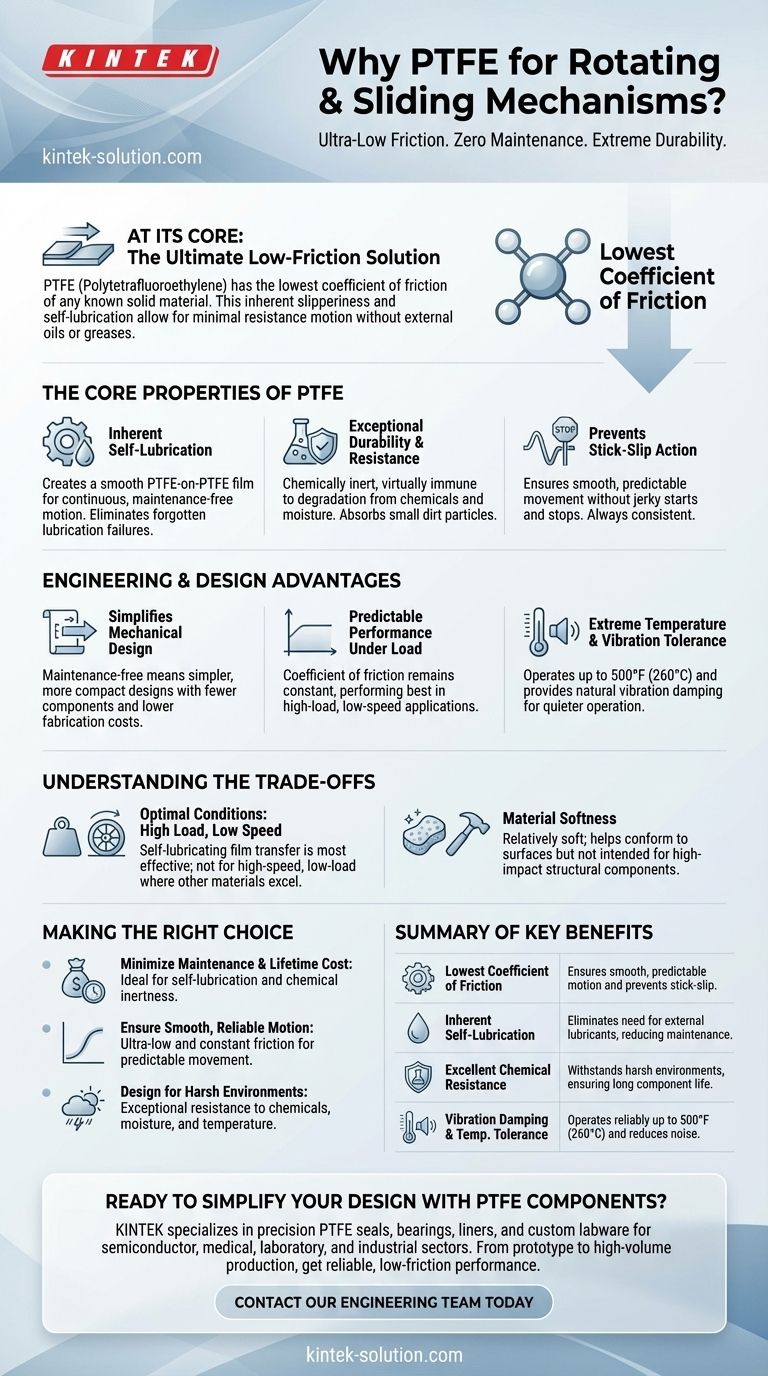

The Core Properties of PTFE

The suitability of Polytetrafluoroethylene (PTFE) goes far beyond just being slippery. Several fundamental material characteristics work together to make it a superior choice for dynamic components.

The Lowest Coefficient of Friction

PTFE's molecular structure gives it an incredibly low coefficient of friction. This is the primary reason it is used for bearings, seals, and other sliding parts.

This property is so effective that it prevents "stick-slip" action, where parts can catch and release, leading to jerky or inconsistent motion. PTFE ensures movement is always smooth and predictable.

Inherent Self-Lubrication

Unlike metal components that require regular lubrication, PTFE is naturally self-lubricating. As parts move, a microscopic film of PTFE is transferred, creating a smooth PTFE-on-PTFE surface.

This eliminates the need for maintenance, reduces the risk of failure from forgotten lubrication, and keeps the system clean from contaminating oils and greases.

Exceptional Durability and Resistance

PTFE is chemically inert, meaning it is virtually immune to degradation from chemicals, weathering, or moisture. This gives components a practically indefinite lifespan in many environments.

Furthermore, it can absorb small dirt particles, preventing them from scoring or damaging moving surfaces, which is a common failure point in traditional bearings.

The Engineering and Design Advantages

Choosing PTFE translates into significant practical benefits during the design, fabrication, and long-term operation of mechanical systems.

Simplifies Mechanical Design

Because PTFE components are maintenance-free and robust, engineers can create simpler and more compact designs. There is no need to incorporate complex lubrication systems or easy-access points for maintenance.

This simplicity often leads to lower fabrication costs, easier installation, and a reduced overall part count.

Predictable Performance Under Load

PTFE's coefficient of friction remains remarkably constant under a wide variety of conditions, including high loads and low speeds.

This predictability is critical for engineers, as it ensures the machine will perform as expected without unexpected changes in friction or behavior. It performs best in high-load, low-speed applications where its self-lubricating properties are most effective.

Extreme Temperature and Vibration Tolerance

PTFE can withstand a very wide temperature range, operating reliably at up to 500°F (260°C) without structural degradation.

It also provides natural vibration damping, which can reduce operational noise and absorb stresses within a mechanism, further increasing the life of surrounding components.

Understanding the Trade-offs

While extremely effective, PTFE's properties make it ideal for specific conditions. Understanding its limitations is key to using it correctly.

Optimal Conditions: High Load, Low Speed

PTFE bearings and slide plates deliver their best performance under high loads and relatively low surface speeds.

In these conditions, the self-lubricating film transfer is most effective. It may not be the optimal choice for high-speed, low-load applications where other bearing materials might excel.

Material Softness

Compared to metals, PTFE is a relatively soft material. While this helps it conform to surfaces and absorb debris, it is not intended for high-impact applications or as a primary structural component where high rigidity is required.

Its strength lies in surface interaction, not in bulk structural integrity.

Making the Right Choice for Your Application

Selecting PTFE is a strategic decision that should align with your primary engineering goal.

- If your primary focus is minimizing maintenance and lifetime cost: PTFE is an ideal choice due to its self-lubricating nature and chemical inertness, which eliminates the need for upkeep.

- If your primary focus is ensuring smooth, reliable motion: PTFE's ultra-low and constant coefficient of friction guarantees predictable movement and prevents the stick-slip action that plagues other systems.

- If your primary focus is designing for harsh environments: The material's exceptional resistance to chemicals, moisture, and extreme temperatures makes it one of the most durable choices available.

By leveraging these properties, you can design mechanical systems that are simpler, more reliable, and more durable.

Summary Table:

| Key Property | Benefit for Rotating/Sliding Mechanisms |

|---|---|

| Lowest Coefficient of Friction | Ensures smooth, predictable motion and prevents stick-slip. |

| Inherent Self-Lubrication | Eliminates need for external lubricants, reducing maintenance. |

| Excellent Chemical Resistance | Withstands harsh environments, ensuring long component life. |

| Vibration Damping & Temperature Tolerance | Operates reliably from cryogenic to 500°F (260°C) and reduces noise. |

Ready to simplify your design and eliminate maintenance with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, bearings, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or high-volume production, our expertise ensures you get components that deliver reliable, low-friction performance.

Contact our engineering team today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech