Polytetrafluoroethylene (PTFE) is highly regarded because it delivers an unmatched combination of three core properties: extreme chemical resistance, high-temperature stability, and an exceptionally low-friction surface. Known commercially as Teflon, this fluoroplastic solves engineering challenges that few other materials can, making it indispensable in sectors from aerospace and medicine to manufacturing and consumer goods.

PTFE's reputation isn't built on a single feature, but on its rare combination of near-total chemical inertness, elite thermal stability, and an extremely slick, non-stick surface. This unique trio makes it a default problem-solver across countless demanding industries.

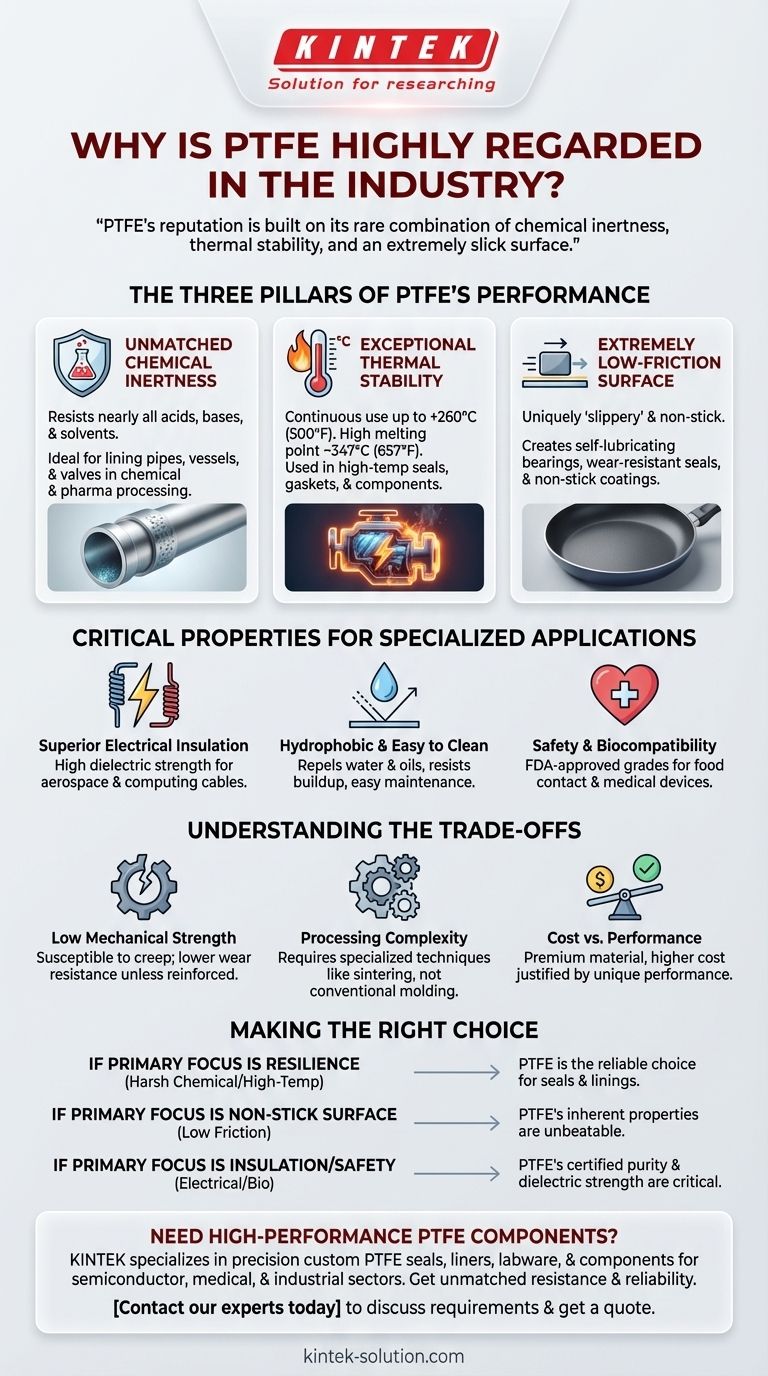

The Three Pillars of PTFE's Performance

PTFE's elite status comes from a synthesis of properties that work together. Understanding these three primary strengths explains why it is so frequently specified for critical applications.

Pillar 1: Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It can withstand sustained contact with nearly all industrial chemicals, acids, and bases without degrading.

This makes it the premier choice for lining pipes, vessels, and valves that handle highly corrosive materials in chemical processing and pharmaceutical manufacturing.

Pillar 2: Exceptional Thermal Stability

With a continuous working temperature of up to +260°C (500°F), PTFE has the highest thermal stability of any fluoroplastic. Its melting point is exceptionally high, around 347°C (657°F).

This allows it to be used in high-temperature seals, gaskets, and components in engines and industrial machinery. It also enables its use in high-performance hair styling tools that require consistent, high heat.

Pillar 3: An Extremely Low-Friction Surface

PTFE possesses one of the lowest coefficients of friction of any solid material. This gives it a uniquely "slippery" or non-stick quality.

This property is fundamental to its use as a coating on cookware but is also critical for creating self-lubricating bearings, wear-resistant seals, and surfaces that resist the buildup of contaminants.

Critical Properties for Specialized Applications

Beyond the three pillars, other key characteristics expand PTFE's utility into highly specific and regulated fields.

Superior Electrical Insulation

PTFE has very high electrical resistance, making it an excellent insulator. It is frequently used for insulating high-performance wires and cables, especially in aerospace and computing where signal integrity is paramount.

Hydrophobic and Easy to Clean

The material naturally repels water and oils, a property known as hydrophobicity. This resistance, combined with its low-friction surface, makes it extremely easy to clean and maintain.

Safety and Biocompatibility

Certain grades of PTFE are non-toxic and approved by agencies like the FDA for food contact. Its inertness also makes it suitable for many medical applications, including implants and surgical equipment.

Understanding the Trade-offs

While its performance is outstanding, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Relatively Low Mechanical Strength

Compared to metals or engineering plastics like PEEK, PTFE is a relatively soft material. It can be susceptible to "creep" or deformation under sustained load and has lower wear resistance in high-abrasion scenarios unless reinforced with fillers.

Processing Complexity

PTFE's high melting point and high melt viscosity make it more difficult to process than common thermoplastics. It cannot be injection molded or extruded using conventional methods, requiring specialized techniques like compression molding and sintering.

Cost vs. Performance

While the references note an excellent price-to-performance ratio, PTFE is a premium material. Its cost is higher than that of commodity plastics, so its use is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Selecting PTFE is a decision driven by a specific, demanding need. Its value is most apparent when environmental conditions are too extreme for conventional materials.

- If your primary focus is resilience in harsh chemical or high-temperature environments, PTFE is often the default and most reliable choice for seals, linings, and components.

- If your primary focus is creating a non-stick, low-friction surface, PTFE's inherent properties as a coating or solid material are nearly impossible to beat.

- If your primary focus is high-performance electrical insulation or ensuring material safety for food or medical use, PTFE's certified purity and high dielectric strength are critical advantages.

Ultimately, PTFE's value lies in its unique ability to perform reliably where other materials would quickly fail.

Summary Table:

| Key Property | Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists nearly all acids, bases, and solvents | Chemical processing liners, labware, seals |

| Thermal Stability | Continuous use up to 260°C (500°F) | High-temp seals, gaskets, industrial components |

| Low Friction | Extremely slippery, non-stick surface | Non-stick coatings, self-lubricating bearings |

| Electrical Insulation | Excellent dielectric strength | Aerospace wiring, high-performance cables |

| Biocompatibility | FDA-approved, non-toxic, inert | Medical devices, food processing equipment |

Need high-performance PTFE components that can withstand your most demanding environments?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, labware, and components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures you get parts that deliver unmatched chemical resistance, thermal stability, and reliability.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance