To put it simply, PTFE (polytetrafluoroethylene) is an ideal material for butterfly valves because of its unique combination of extreme chemical inertness and an incredibly low coefficient of friction. This allows a PTFE-seated valve to provide a bubble-tight seal against the most aggressive chemicals while requiring very low torque to operate, ensuring a long and reliable service life where other materials would quickly fail.

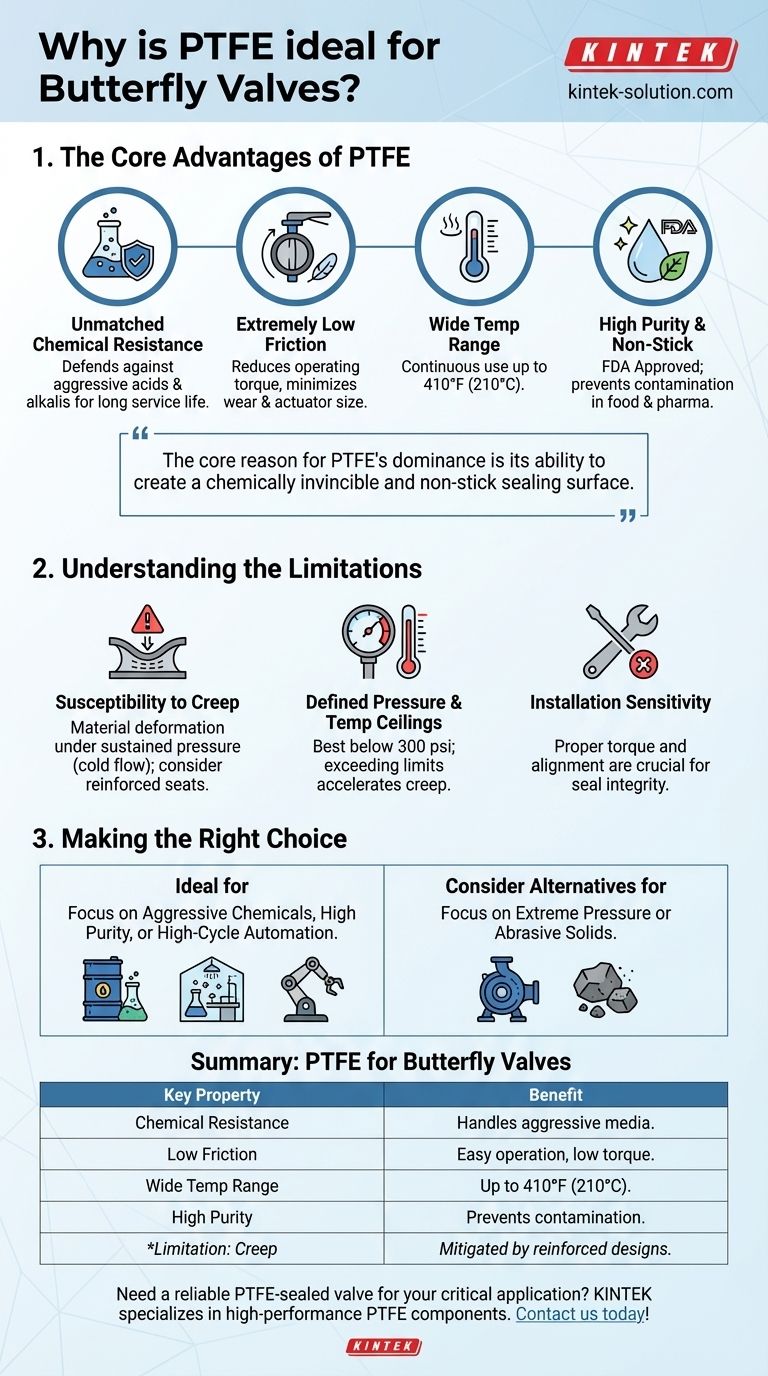

The core reason for PTFE's dominance in high-performance valves is its ability to create a chemically invincible and non-stick sealing surface. This solves the fundamental challenge of handling corrosive or high-purity media without contamination or mechanical failure.

The Core Properties of PTFE for Valve Performance

To understand why PTFE is so effective, we must look at its specific material properties and how they directly translate to superior valve function.

Unmatched Chemical Resistance

The primary advantage of PTFE is its status as one of the most chemically inert polymers known.

It provides exceptional resistance to a vast range of media, including strong acids, strong alkalis, and other highly corrosive substances. This makes PTFE-lined valves the standard choice for harsh chemical processing environments.

Extremely Low Friction Coefficient

PTFE has one of the lowest friction coefficients of any solid material, often compared to wet ice on wet ice.

This "non-stick" quality is critical for a butterfly valve. It allows the valve disc to rotate and seal against the PTFE seat with minimal force, reducing the size and cost of the actuator. Most importantly, it dramatically minimizes wear and tear, preventing galling and extending the valve's operational life.

Wide Operating Temperature Range

PTFE maintains its integrity across a broad spectrum of temperatures.

It is generally suitable for continuous service in conditions up to 410°F (210°C). This thermal stability allows it to be used in a wide array of industrial processes without degradation.

Purity and Contamination Control

PTFE is inherently pure and resistant to adhesion, which is why it is widely FDA approved for food and pharmaceutical applications.

Its non-stick surface prevents media from clinging to the valve components, ensuring a clean and uncontaminated flow. This is essential for any process where product purity is non-negotiable.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its mechanical limitations.

Susceptibility to Creep

The most significant mechanical limitation of PTFE is creep, or cold flow. Under sustained pressure and temperature, the material can slowly deform.

This can be a concern for the long-term sealing capability of a valve seat. High-performance valve designs often mitigate this by using energized or reinforced PTFE seats to improve creep resistance.

Defined Pressure and Temperature Ceilings

While its operating range is wide, it is not infinite. PTFE's performance can degrade in applications that exceed its design limits.

As a general guideline, standard PTFE seats are best suited for applications below 300 psi. Exceeding these pressure or temperature limits can accelerate creep and lead to premature seal failure.

Installation Sensitivity

The effectiveness of a PTFE seal is highly dependent on proper installation.

Misalignment of the valve, improper gasket selection, or incorrect bolt torquing can create uneven stress on the PTFE seat. This can compromise the seal and negate the material's inherent benefits.

Making the Right Choice for Your Application

Selecting the right valve material comes down to matching its properties to the demands of your specific process.

- If your primary focus is aggressive chemicals: PTFE is the definitive choice for handling corrosive media that would destroy elastomers or metal seats.

- If your primary focus is high purity: The inert, non-stick, and FDA-approved nature of PTFE makes it essential for food, beverage, and pharmaceutical applications.

- If your primary focus is high-cycle automation: PTFE's low friction reduces actuator torque requirements and minimizes seat wear, making it ideal for automated systems.

- If your process involves high pressure or abrasive solids: You must verify that your conditions are within PTFE's limits and consider alternative materials like metal-seated valves for more extreme service.

By understanding these distinct properties and limitations, you can confidently specify PTFE-lined valves for applications where chemical resistance and reliability are paramount.

Summary Table:

| Key Property | Benefit for Butterfly Valves |

|---|---|

| Extreme Chemical Resistance | Handles aggressive acids, alkalis, and solvents without degradation. |

| Low Coefficient of Friction | Ensures easy operation, low torque, and reduced wear for long service life. |

| Wide Temperature Range | Suitable for continuous use up to 410°F (210°C). |

| High Purity & Non-Stick | Prevents contamination, ideal for food, pharma, and high-purity processes. |

| Limitation: Creep | Can deform under sustained pressure; mitigated by reinforced seat designs. |

Need a reliable PTFE-sealed valve for your critical application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom seals and liners for butterfly valves. Our precision engineering ensures bubble-tight sealing and long-term reliability in the most demanding environments—from semiconductor manufacturing to pharmaceutical processing.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact specifications.

Contact us today to discuss your valve requirements and get a solution that withstands aggressive chemicals while ensuring operational efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability