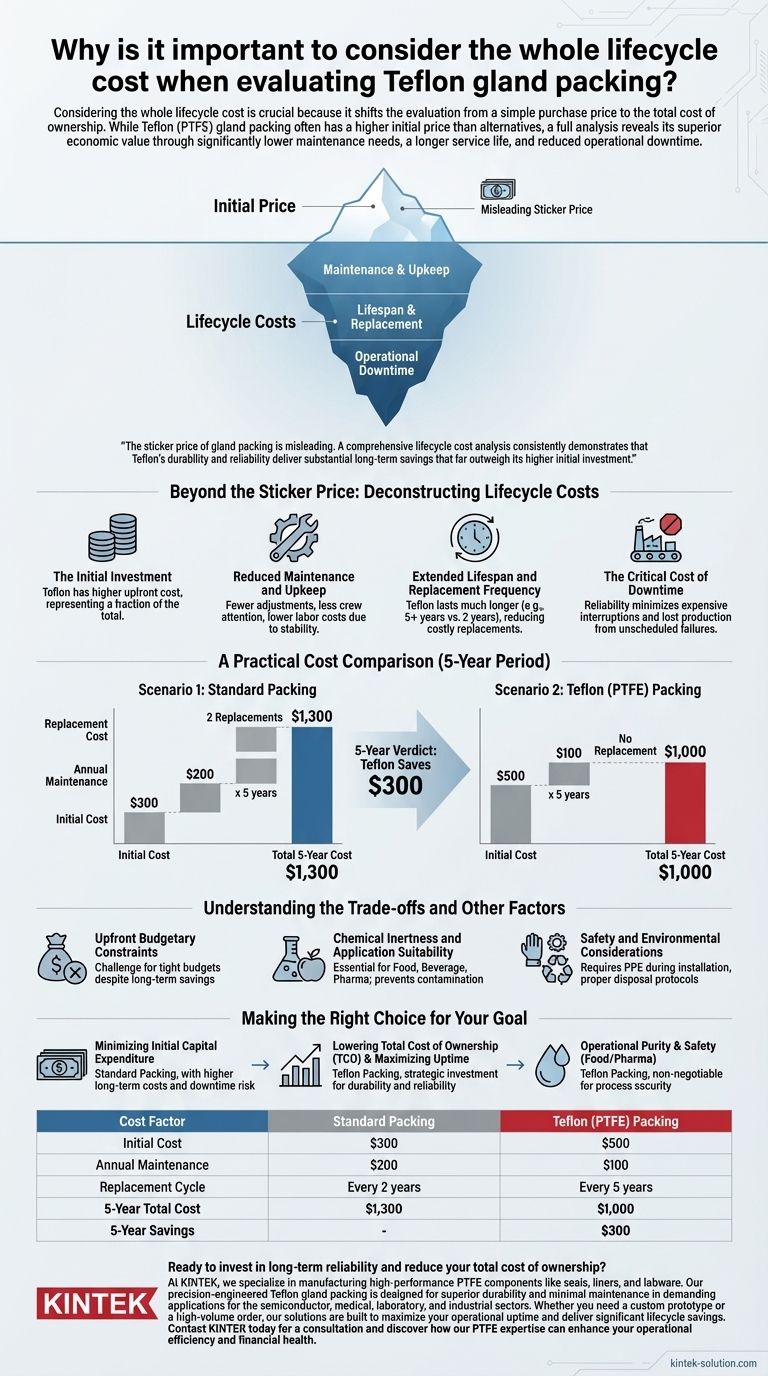

Considering the whole lifecycle cost is crucial because it shifts the evaluation from a simple purchase price to the total cost of ownership. While Teflon (PTFE) gland packing often has a higher initial price than alternatives, a full analysis reveals its superior economic value through significantly lower maintenance needs, a longer service life, and reduced operational downtime.

The sticker price of gland packing is misleading. A comprehensive lifecycle cost analysis consistently demonstrates that Teflon's durability and reliability deliver substantial long-term savings that far outweigh its higher initial investment.

Beyond the Sticker Price: Deconstructing Lifecycle Costs

To truly understand the value of Teflon packing, we must look beyond the initial invoice and analyze the costs incurred throughout its entire service life.

The Initial Investment

Teflon packing typically carries a higher upfront cost compared to many standard packing materials. This is the figure that is easiest to see, but it represents only a fraction of the total financial picture.

Reduced Maintenance and Upkeep

One of the most significant long-term savings comes from reduced maintenance. Teflon packing's stability and resilience mean fewer adjustments and less frequent attention from maintenance crews, directly cutting down on labor hours and associated costs.

Extended Lifespan and Replacement Frequency

Teflon packing has a demonstrably longer lifespan. Where a standard packing might last only two years, a Teflon-based solution can often perform reliably for five years or more under the same conditions, drastically reducing the frequency of costly replacement cycles.

The Critical Cost of Downtime

The most significant hidden cost of cheaper, less durable packing is unscheduled downtime. Every time a line must be stopped to replace a failed packing, you incur costs from lost production, which can dwarf the material cost of the component itself. Teflon's reliability minimizes these expensive interruptions.

A Practical Cost Comparison

Let's examine a clear financial example to illustrate the difference over a five-year period.

Scenario 1: Standard Packing

A standard packing might have an initial cost of $300. With a two-year lifespan and annual maintenance costs of $200, it requires two full replacements over five years. This results in a total cost of approximately $1,300.

Scenario 2: Teflon (PTFE) Packing

Teflon packing has a higher initial cost of $500. However, its annual maintenance is only $100, and with a five-year lifespan, it requires no replacement during this period. The total five-year cost is $1,000.

The Five-Year Verdict

In this direct comparison, the initially more expensive Teflon packing saves $300 over five years. This demonstrates a clear return on investment through superior performance and longevity.

Understanding the Trade-offs and Other Factors

While the financial case is strong, a complete analysis requires acknowledging other critical factors.

Upfront Budgetary Constraints

The primary trade-off is the initial capital outlay. For operations with extremely tight short-term budgets, the higher upfront cost of Teflon can be a challenge, even if it leads to long-term savings.

Chemical Inertness and Application Suitability

PTFE is chemically inert, making it essential for industries like food, beverage, and pharmaceuticals. In these applications, preventing product contamination is paramount, and the material's properties justify the cost independent of maintenance savings.

Safety and Environmental Considerations

While the end product is safe, proper handling during installation is important. Technicians should use appropriate Personal Protective Equipment (PPE) and ensure good ventilation to avoid inhaling any dust. Furthermore, PTFE does not biodegrade, meaning proper disposal protocols must be followed.

Making the Right Choice for Your Goal

Your operational priorities should guide your decision.

- If your primary focus is minimizing initial capital expenditure: Standard packing may be necessary, but you must budget for higher long-term maintenance costs and the financial risk of more frequent downtime.

- If your primary focus is lowering Total Cost of Ownership (TCO) and maximizing uptime: Teflon packing is the clear strategic investment, delivering savings through its exceptional durability and reliability.

- If your primary focus is operational purity and safety (e.g., food or pharma): The chemical inertness of Teflon is a non-negotiable technical advantage that provides essential process security.

By analyzing the full lifecycle cost, you shift from simply buying a component to making a strategic investment in your operational reliability and financial health.

Summary Table:

| Cost Factor | Standard Packing | Teflon (PTFE) Packing |

|---|---|---|

| Initial Cost | $300 | $500 |

| Annual Maintenance | $200 | $100 |

| Replacement Cycle | Every 2 years | Every 5 years |

| 5-Year Total Cost | $1,300 | $1,000 |

| 5-Year Savings | - | $300 |

Ready to invest in long-term reliability and reduce your total cost of ownership?

At KINTEK, we specialize in manufacturing high-performance PTFE components like seals, liners, and labware. Our precision-engineered Teflon gland packing is designed for superior durability and minimal maintenance in demanding applications for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a custom prototype or a high-volume order, our solutions are built to maximize your operational uptime and deliver significant lifecycle savings.

Contact KINTEK today for a consultation and discover how our PTFE expertise can enhance your operational efficiency and financial health.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection