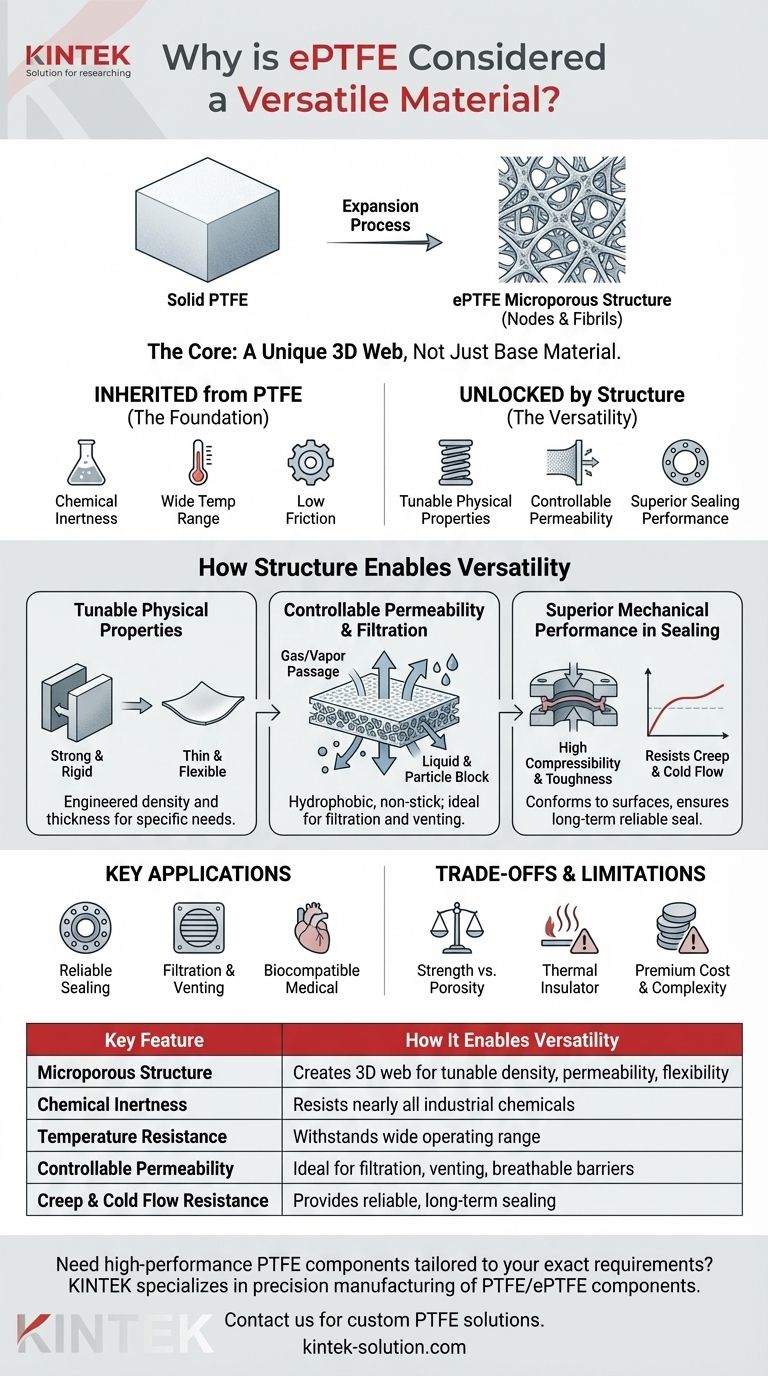

At its core, the versatility of expanded Polytetrafluoroethylene (ePTFE) comes from its unique microporous structure. Unlike solid PTFE, the expansion process creates a web-like material composed of nodes and fibrils, which allows its exceptional inherent properties—like chemical inertness and temperature resistance—to be tailored into countless forms for vastly different applications.

The crucial insight is that ePTFE's adaptability isn't just about the base material. It's about the manufacturing process that transforms solid PTFE into a microscopic, three-dimensional structure, unlocking new capabilities in permeability, strength, and flexibility that solid PTFE cannot offer.

The Foundation: From Solid Plastic to a High-Performance Web

To understand ePTFE's versatility, we must first distinguish it from its parent material, standard PTFE.

Inheriting the Core Strengths of PTFE

ePTFE begins with all the powerful properties of PTFE. These include exceptional chemical resistance against nearly all industrial chemicals, a very wide operating temperature range, and an extremely low coefficient of friction, making it one of the most lubricious materials known.

The Critical Difference: A Microporous Structure

The "expansion" process stretches PTFE, creating a distinctive 3D web. This structure is composed of billions of microscopic pores.

This transformation is the source of its versatility. It turns a solid, impermeable material into one whose density, permeability, and physical form can be precisely controlled.

How Structure Enables Unmatched Versatility

The ability to manipulate ePTFE's microporous structure allows engineers to dial in specific properties required for a given task, from medical implants to industrial gaskets.

Tunable Physical Properties

During manufacturing, ePTFE is created from biaxially-oriented sheets that can be laminated to a desired thickness.

This allows the material to be engineered to be strong and rigid or thin and highly flexible, depending on the needs of the final product.

Controllable Permeability and Filtration

The web-like structure is naturally hydrophobic (water-repellent) and non-stick.

This, combined with its controlled pore size, makes ePTFE an outstanding membrane for filtration. It allows gases to pass through while effectively capturing and shedding fine particulate matter from its surface.

Superior Mechanical Performance in Sealing

In applications like industrial gaskets, ePTFE's multi-fiber structure fundamentally solves problems common to other PTFE seals.

It offers high compressibility to conform to irregular surfaces while providing exceptional toughness. Most importantly, it demonstrates excellent resistance to creep and cold flow—the tendency of a material to deform under sustained pressure—ensuring a more reliable long-term seal.

Understanding the Trade-offs and Limitations

No material is perfect for every scenario. Acknowledging the trade-offs is key to making an informed decision.

Mechanical Strength vs. Porosity

There is an inherent trade-off between the material's porosity and its tensile strength. A highly porous, breathable version of ePTFE will not possess the same rigidity or load-bearing capacity as a denser variant or solid PTFE.

Thermal Conductivity

While it has excellent temperature resistance, the porous nature of ePTFE makes it a thermal insulator. In applications where heat dissipation is critical, this property must be carefully considered.

Cost and Complexity

The specialized manufacturing process required to create ePTFE makes it a premium material. Its cost is generally higher than that of standard PTFE or other commodity sealing and membrane materials.

Making the Right Choice for Your Goal

Selecting ePTFE is about matching its unique structural benefits to a specific engineering challenge.

- If your primary focus is reliable sealing: ePTFE's ability to conform to any flange shape while resisting creep and cold flow makes it a superior choice for critical industrial applications.

- If your primary focus is filtration or venting: The material's hydrophobic, non-stick, and microporous nature is ideal for separating particulates or allowing gas exchange while blocking liquids.

- If your primary focus is a biocompatible application: ePTFE's combination of chemical inertness, flexibility, and porous structure makes it a proven material for medical devices and implants.

By understanding how its unique structure modifies its core properties, you can leverage ePTFE to solve engineering problems that commodity materials cannot address.

Summary Table:

| Key Feature | How It Enables Versatility |

|---|---|

| Microporous Structure | Creates a 3D web for tunable density, permeability, and flexibility |

| Chemical Inertness | Inherits PTFE's resistance to nearly all industrial chemicals |

| Temperature Resistance | Withstands a wide operating temperature range |

| Controllable Permeability | Ideal for filtration, venting, and breathable barriers |

| Creep & Cold Flow Resistance | Provides reliable, long-term sealing performance |

Need high-performance PTFE components tailored to your exact requirements?

At KINTEK, we specialize in precision manufacturing of PTFE and ePTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your materials meet the highest standards for performance and reliability.

Contact us today to discuss how our custom PTFE solutions can solve your unique engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability