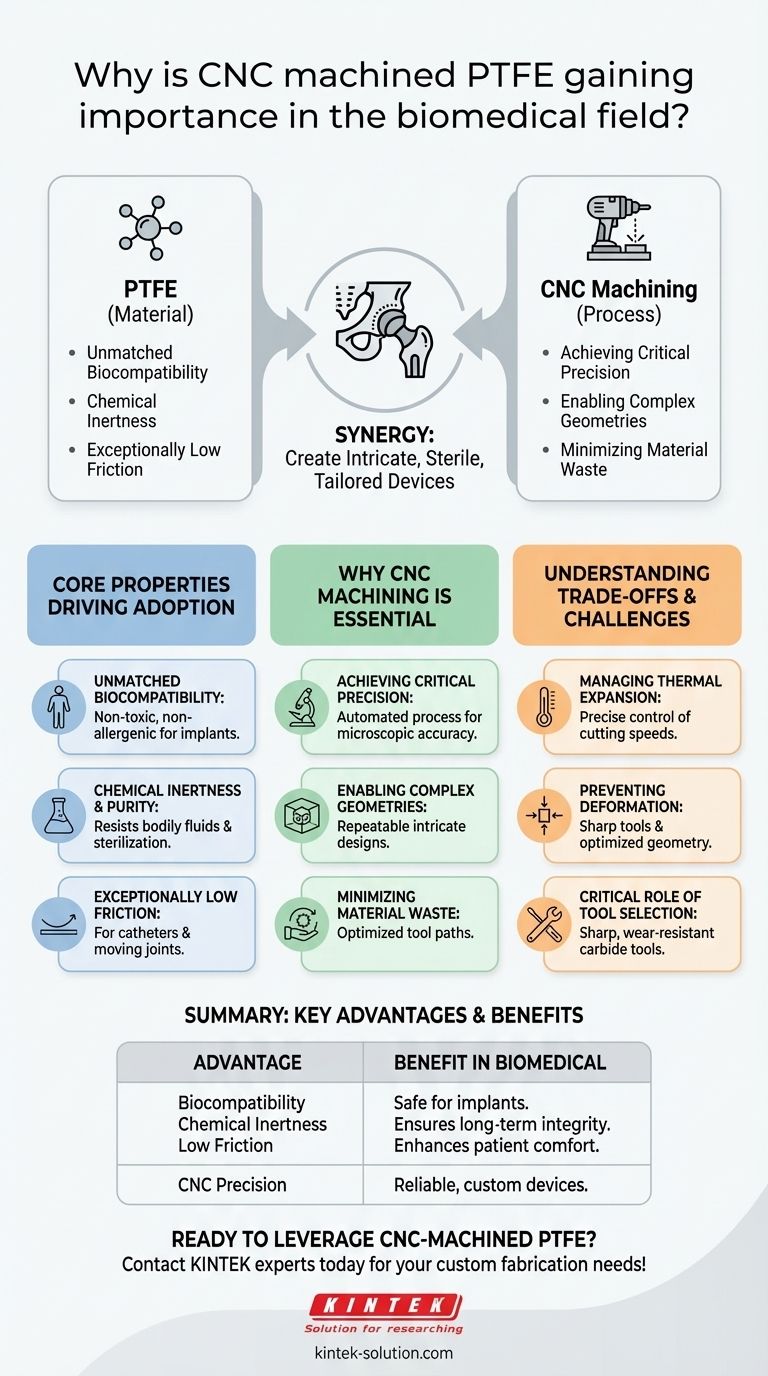

To be direct, CNC machined PTFE is gaining critical importance in the biomedical field because it uniquely combines two essential attributes: the material's inherent biocompatibility, which makes it safe for use within the human body, and the high precision of CNC machining, which is required to produce the complex, life-sustaining medical components modern technology demands. This synergy allows for the creation of advanced implants and surgical instruments with unparalleled safety and performance.

The core reason for its rise is not just the material (PTFE) or the process (CNC) in isolation. It is the powerful combination of the two that unlocks the ability to manufacture intricate, sterile, and perfectly tailored medical devices that were once unfeasible.

The Core Properties Driving Adoption

The selection of any material for medical use is subject to intense scrutiny. PTFE, often known by the brand name Teflon, possesses a set of properties that make it exceptionally well-suited for the demanding environment of the human body.

Unmatched Biocompatibility

PTFE is one of the most biocompatible polymers available. It is non-toxic and non-allergenic, meaning the human body's immune system does not react to its presence, which is a fundamental requirement for any implantable device.

Chemical Inertness and Purity

The material is chemically inert, so it will not degrade when exposed to bodily fluids or the aggressive chemicals used in sterilization processes. This ensures the long-term integrity and safety of the medical component.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This "slipperiness" is highly valuable for applications like catheters or components in moving joints, where minimizing friction is critical to performance and patient comfort.

Why CNC Machining is the Essential Process

While PTFE has the right properties, it is the manufacturing process that makes it truly viable for advanced biomedical applications. CNC (Computer Numerical Control) machining provides the necessary control and precision.

Achieving Critical Precision

Medical devices demand incredibly tight tolerances. CNC machining is an automated process that translates a digital design into a physical part with microscopic accuracy, drastically reducing the error rates common in manual methods.

Enabling Complex Geometries

Modern surgical instruments and custom implants often have highly intricate designs. CNC machining can create these complex shapes and features repeatably, ensuring that every part meets the exact design specifications.

Minimizing Material Waste

The CNC process is optimized for efficiency. By carefully planning the tool path, it's possible to produce components with minimal material waste, which is important when working with specialized and costly medical-grade materials.

Understanding the Trade-offs and Machining Challenges

Machining PTFE is not without its challenges. The material's unique properties require specific expertise and process control, which CNC technology is perfectly suited to manage.

Managing Thermal Expansion

PTFE has a high rate of thermal expansion, meaning it can deform or change size when heated by the friction of a cutting tool. CNC machines allow for precise control over cutting speeds and feeds to minimize heat generation and ensure dimensional stability.

Preventing Deformation

As a relatively soft material, PTFE can be easily compressed or deformed by improper tool pressure or clamping. The right machining strategy involves using extremely sharp tools and optimized tool geometry, such as large front angles, to cut the material cleanly with minimal force.

The Critical Role of Tool Selection

Tool choice is paramount for a high-quality finish. Sharp, wear-resistant tools, such as those made from carbide, are essential to prevent material adhesion and ensure a clean cut rather than tearing the polymer.

How to Apply This to Your Project

The decision to use CNC machined PTFE should be directly tied to your project's most critical requirements.

- If your primary focus is creating sterile, non-reactive surgical tools: PTFE's chemical inertness and ability to be machined into precise, functional shapes make it an ideal choice.

- If your primary focus is developing custom implants with complex geometries: The combination of PTFE's biocompatibility and CNC's precision offers a definitive solution for patient-specific devices.

- If your primary focus is high-volume production of consistent medical components: The repeatability and low error rate of CNC machining PTFE minimizes waste and ensures every part meets stringent quality standards.

Ultimately, leveraging CNC-machined PTFE empowers engineers and medical innovators to build the next generation of safer and more effective medical devices.

Summary Table:

| Key Advantage | Benefit in Biomedical Applications |

|---|---|

| Biocompatibility | Non-toxic, non-allergenic; safe for implants and surgical tools. |

| Chemical Inertness | Resists bodily fluids and sterilization chemicals; ensures long-term integrity. |

| Low Friction | Ideal for catheters and joint components; enhances patient comfort. |

| CNC Precision | Achieves tight tolerances and complex geometries for reliable, custom devices. |

Ready to leverage CNC-machined PTFE for your biomedical project? KINTEK specializes in precision manufacturing of PTFE components (seals, liners, labware, and custom parts) for the medical, semiconductor, and laboratory industries. From prototypes to high-volume orders, we ensure your devices meet the highest standards of safety and performance. Contact our experts today to discuss your custom fabrication needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers