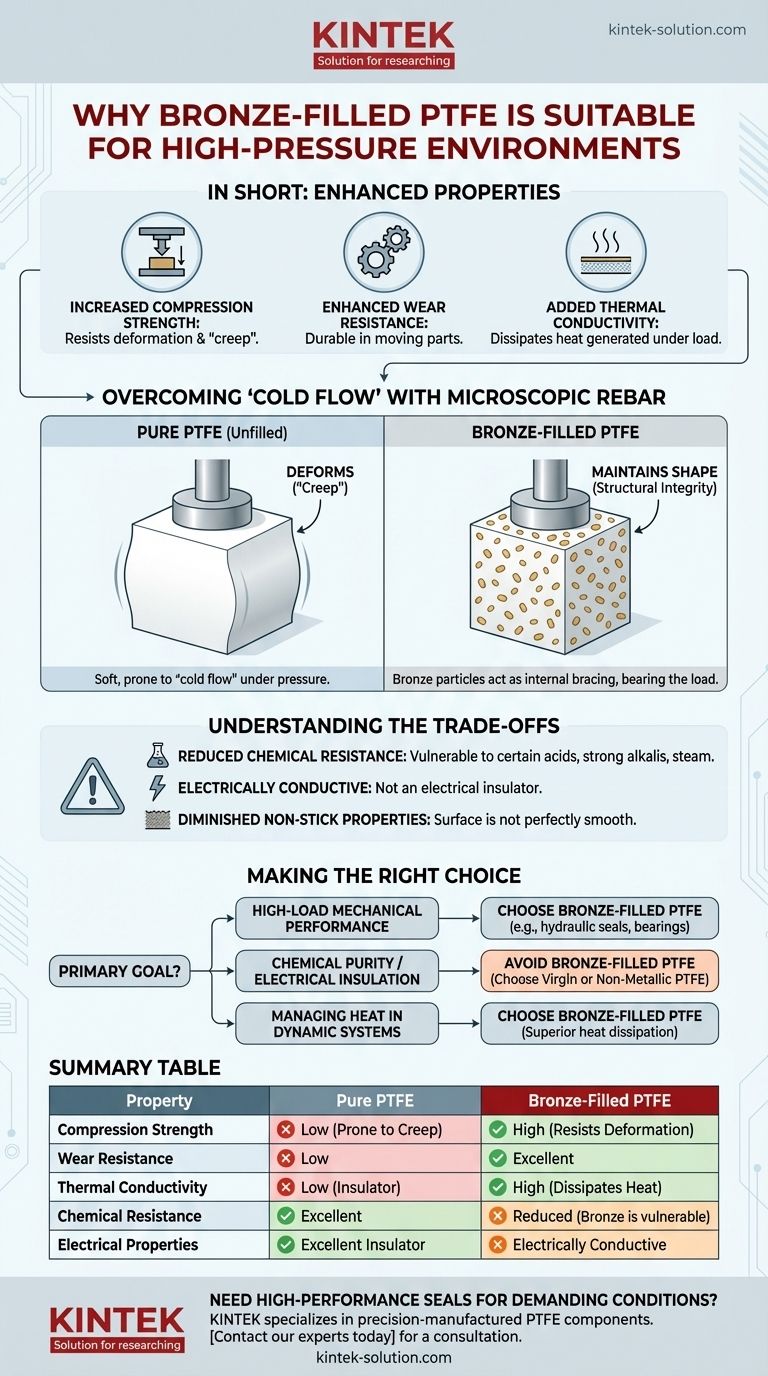

In short, bronze-filled PTFE is suitable for high-pressure environments because the bronze filler dramatically improves the mechanical properties of pure PTFE. It significantly increases compression strength to resist deformation, enhances wear resistance for durability in moving parts, and adds thermal conductivity to dissipate heat generated under load. These enhancements directly address the primary failure points of unfilled polymers in high-pressure applications.

Unfilled PTFE, while chemically resistant and low-friction, is mechanically soft and prone to deforming under pressure—a phenomenon known as "creep." Adding bronze filler is the critical engineering solution that imbues PTFE with the necessary structural integrity to maintain its shape and function in high-load, high-pressure conditions.

The Role of Bronze in Fortifying PTFE

To understand why this composite material excels, you must first recognize the inherent weakness of pure PTFE. Think of pure PTFE as soft modeling clay; it's malleable and slick, but it permanently deforms when you squeeze it.

Overcoming "Cold Flow" Under Pressure

Pure PTFE suffers from cold flow, or creep, meaning it will slowly deform and "flow" away from a constant pressure point, even at room temperature. This makes it unreliable for holding a tight seal under high pressure.

The bronze particles mixed into the PTFE matrix act like a microscopic rebar in concrete. They provide a rigid internal structure that braces the softer polymer, drastically reducing creep and allowing the material to withstand high compressive loads without losing its shape.

Enhancing Compression and Wear Resistance

The addition of up to 60% bronze powder by weight significantly increases the material's hardness and compression strength.

This makes it exceptionally durable in dynamic applications, such as hydraulic piston rings or bearings, where it must endure both constant pressure and the friction of moving surfaces. The bronze particles bear the mechanical load and resist abrasion, protecting the softer PTFE.

Managing Heat in Demanding Systems

High-pressure systems generate heat, both from friction and the compression of fluids. Pure PTFE is a thermal insulator, meaning it traps this heat, which can cause it to expand and fail.

Bronze is an excellent thermal conductor. It draws heat away from the sealing or bearing surface and dissipates it into the surrounding assembly. This thermal management is crucial for applications with frequent starts and stops, preventing overheating and ensuring consistent performance.

Understanding the Trade-offs

Adding bronze filler is a targeted engineering choice, and it comes with specific compromises. It is not a universal upgrade for all PTFE applications.

Reduced Chemical Resistance

The primary trade-off is a loss of chemical inertness. While PTFE itself is resistant to nearly all chemicals, the bronze filler is not.

Bronze-filled PTFE is susceptible to attack by corrosive agents that affect bronze, such as certain acids, strong alkalis, and steam. Its use in chemically aggressive environments must be carefully evaluated.

Altered Electrical Properties

Pure PTFE is an excellent electrical insulator. The inclusion of metallic bronze particles makes the composite material electrically conductive.

This property can be beneficial for dissipating static electricity in some applications but makes it entirely unsuitable for any use case that requires electrical insulation.

Diminished Non-Stick Properties

While the coefficient of friction remains low, the bronze particles interrupt the uniquely smooth, non-stick surface of pure PTFE. For applications where a perfect, easy-release surface is the primary goal, bronze-filled variants are not the ideal choice.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational goal. Bronze-filled PTFE excels where mechanical demands are the priority.

- If your primary focus is high-load mechanical performance: Choose bronze-filled PTFE for applications like hydraulic seals, piston rings, and bearings that require high compression strength and wear resistance.

- If your primary focus is chemical purity or electrical insulation: Avoid bronze-filled PTFE. Virgin PTFE or PTFE with a non-metallic filler (like glass or carbon) is the appropriate choice.

- If your primary focus is managing heat in a dynamic system: Bronze-filled PTFE's high thermal conductivity makes it a superior choice over other formulations for dissipating frictional heat.

By understanding this balance of properties, you can confidently specify the right material for the demanding conditions of your high-pressure system.

Summary Table:

| Property | Pure PTFE | Bronze-Filled PTFE |

|---|---|---|

| Compression Strength | Low (Prone to Creep) | High (Resists Deformation) |

| Wear Resistance | Low | Excellent |

| Thermal Conductivity | Low (Insulator) | High (Dissipates Heat) |

| Chemical Resistance | Excellent | Reduced (Bronze is vulnerable) |

| Electrical Properties | Excellent Insulator | Electrically Conductive |

Need high-performance seals or components for demanding conditions?

KINTEK specializes in precision-manufactured PTFE components, including custom bronze-filled formulations for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your high-pressure systems benefit from superior compression strength, wear resistance, and thermal management.

Let us help you solve your toughest engineering challenges—from prototypes to high-volume production. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection