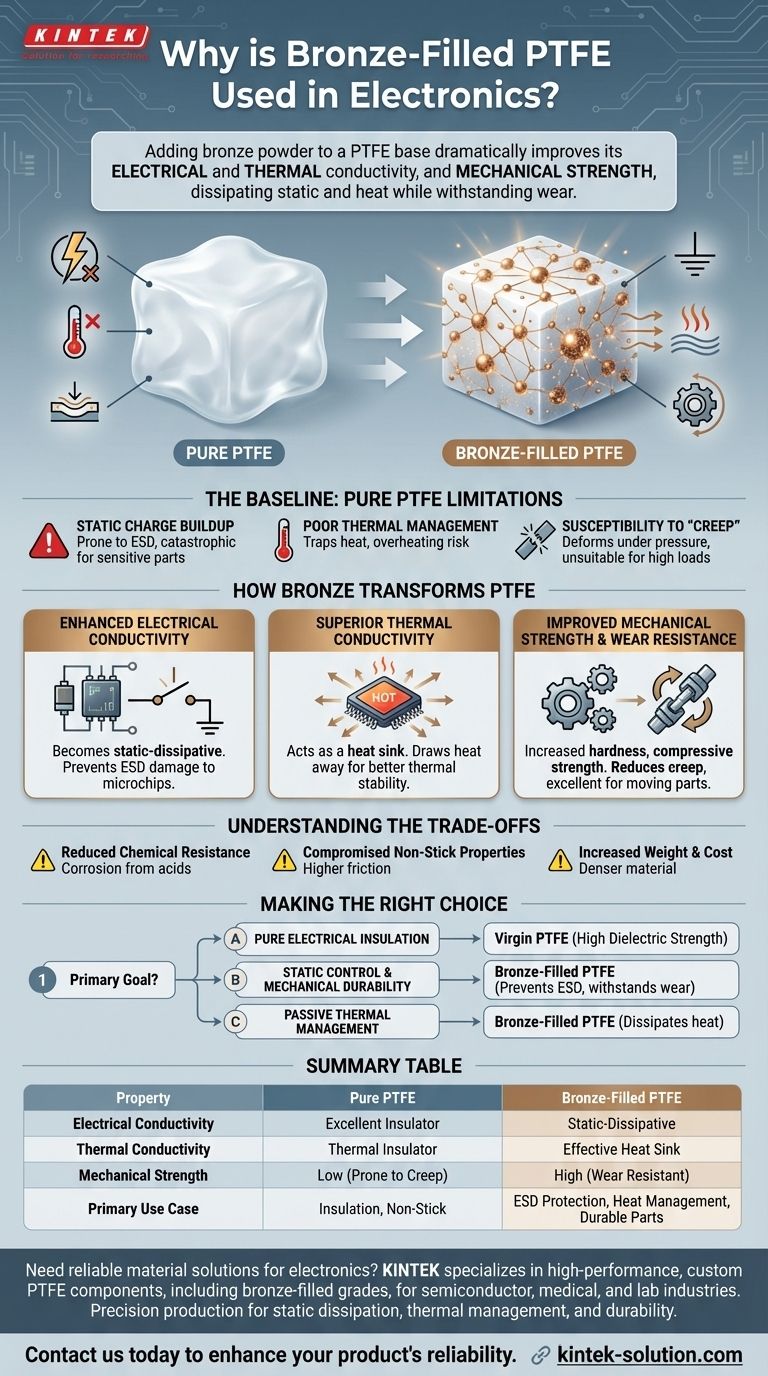

To put it simply, bronze-filled PTFE is used in electronics because adding bronze powder to a PTFE base dramatically improves its electrical and thermal conductivity, along with its mechanical strength. This unique combination allows it to dissipate static electricity and heat while withstanding physical wear, solving problems that pure PTFE cannot.

The core challenge in many electronic applications is finding a material that is both mechanically robust and can manage electrical and thermal loads. While pure PTFE is an excellent insulator, the addition of bronze transforms it into a semi-conductive composite capable of safely grounding static charge and drawing away damaging heat.

The Baseline: Why Pure PTFE Falls Short

To understand the value of bronze-filled PTFE, you must first understand the limitations of pure, unfilled PTFE in certain electronic contexts.

Excellent but Problematic Insulation

Pure PTFE (polytetrafluoroethylene) is one of the best electrical insulators known. This makes it ideal for wire jacketing and cable insulation where you need to prevent electrical current from escaping.

However, this same property means it is prone to static charge buildup. In environments with sensitive electronic components, an uncontrolled electrostatic discharge (ESD) can be catastrophic.

Poor Thermal Management

PTFE is also a thermal insulator. It does not transfer heat well. When used in or near components that generate heat—like processors or power regulators—it can trap that heat, leading to overheating and potential failure.

Susceptibility to "Creep"

While durable, pure PTFE is a relatively soft material. Under sustained pressure, it can deform or "creep" over time. This lack of dimensional stability makes it unsuitable for high-load mechanical parts like precision sockets or durable connectors.

How Bronze Fillers Transform PTFE's Properties

Adding bronze powder (typically up to 60% by weight) fundamentally alters the material's behavior, creating a composite that solves the core issues of pure PTFE for specific applications.

Enhanced Electrical Conductivity for Static Dissipation

The primary benefit in electronics is the move from an insulator to a static-dissipative material. The bronze particles create a network within the PTFE that allows electrical charges to flow safely to a ground.

This prevents the buildup of static electricity, protecting sensitive microchips and other components from ESD damage. It is not conductive enough to be a wire, but it is conductive enough to eliminate static hazards.

Superior Thermal Conductivity for Heat Management

Bronze is an excellent thermal conductor. Distributing it throughout the PTFE base allows the entire component to act as a heat sink.

The material can draw thermal energy away from a hot chip or circuit and dissipate it into the surrounding environment, significantly improving the thermal stability and reliability of the electronic assembly.

Improved Mechanical Strength and Wear Resistance

Bronze is a hard metal alloy. Adding it as a filler dramatically increases the hardness, compressive strength, and wear resistance of the PTFE.

This makes the material far more durable for applications involving repeated physical contact, such as in test sockets, connectors, or bearings within automated electronic equipment like printers and disk drives. It also significantly reduces the tendency to creep under load.

Understanding the Trade-offs

No material is perfect. The advantages gained by adding bronze come with a few key compromises.

Reduced Chemical Resistance

Pure PTFE is famously inert and resistant to nearly all chemicals. Bronze is not. The presence of bronze particles means the composite material is susceptible to corrosion from certain acids and other aggressive chemicals.

Compromised Non-Stick Properties

The low-friction, non-stick surface is a hallmark of PTFE. The bronze filler particles interrupt this smooth surface, slightly increasing the coefficient of friction and reducing its non-stick quality.

Increased Weight and Cost

Adding a dense metal powder to a lightweight polymer base naturally increases the final part's weight and cost. This must be factored into any design consideration.

Making the Right Choice for Your Application

Choosing the correct material depends entirely on your primary engineering goal.

- If your primary focus is pure electrical insulation: Unfilled, virgin PTFE remains the superior choice due to its exceptionally high dielectric strength.

- If your primary focus is static control and mechanical durability: Bronze-filled PTFE is the ideal candidate for components that need to prevent ESD while enduring physical wear.

- If your primary focus is passive thermal management: Bronze-filled PTFE is an excellent option for structural parts that must also help dissipate heat from nearby components.

Ultimately, bronze-filled PTFE provides a unique balance of properties that solves a specific set of engineering challenges where no single material would suffice.

Summary Table:

| Property | Pure PTFE | Bronze-Filled PTFE |

|---|---|---|

| Electrical Conductivity | Excellent Insulator | Static-Dissipative |

| Thermal Conductivity | Thermal Insulator | Effective Heat Sink |

| Mechanical Strength | Low (Prone to Creep) | High (Wear Resistant) |

| Primary Use Case | Insulation, Non-Stick | ESD Protection, Heat Management, Durable Parts |

Need a reliable material solution for your electronic components?

KINTEK specializes in manufacturing high-performance, custom PTFE components, including bronze-filled grades, for the semiconductor, medical, and laboratory industries. Our precision production ensures your parts meet exact specifications for static dissipation, thermal management, and mechanical durability—from prototypes to high-volume orders.

Contact us today to discuss how our PTFE expertise can enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F