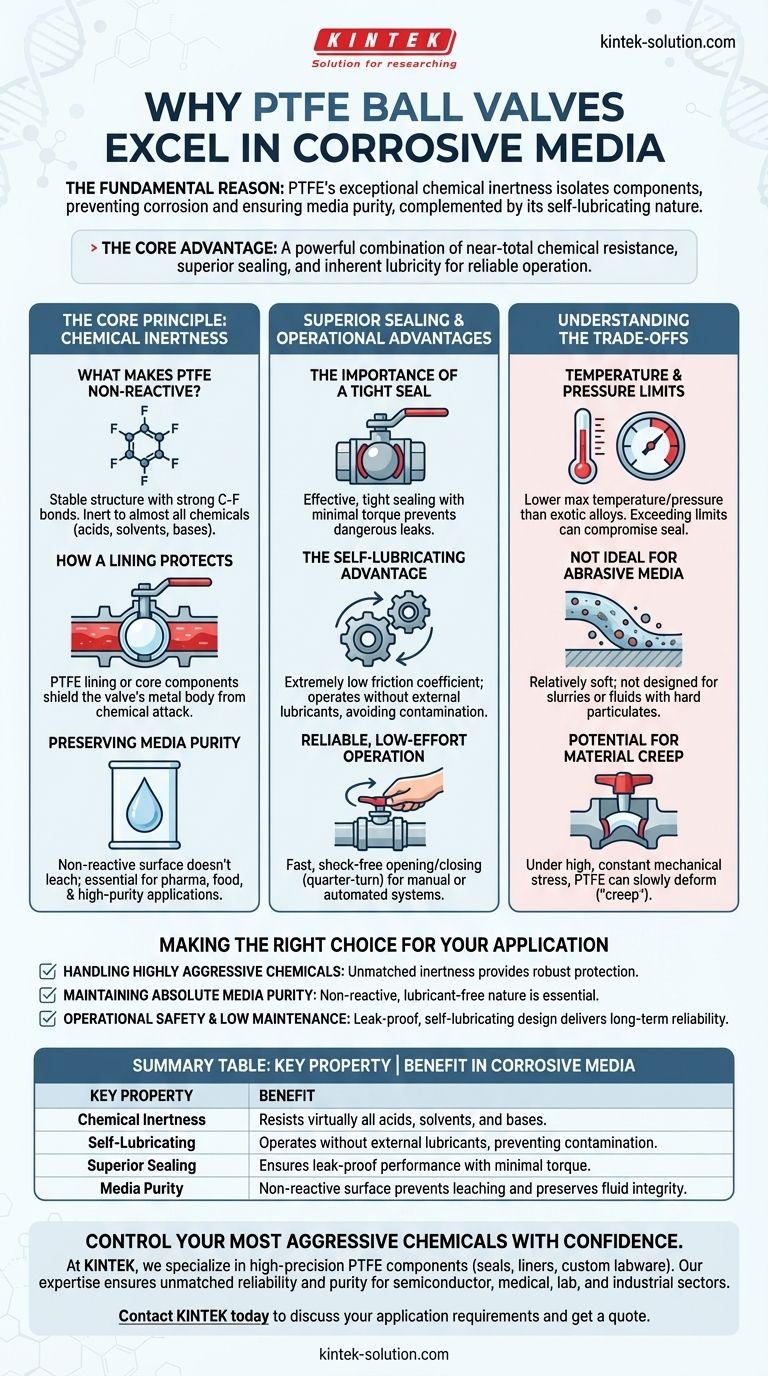

The fundamental reason PTFE ball valves excel in corrosive media is the material's exceptional chemical inertness. Polytetrafluoroethylene (PTFE) is a non-reactive polymer that effectively isolates the valve's structural components from aggressive chemicals, preventing corrosion and ensuring the purity of the media being controlled. This is complemented by its self-lubricating nature, which eliminates the risk of contamination from external lubricants.

The core advantage is not just one feature, but a powerful combination: PTFE's near-total chemical resistance provides protection, its superior sealing capabilities prevent dangerous leaks, and its inherent lubricity ensures reliable operation without contamination.

The Core Principle: Chemical Inertness

The primary value of PTFE in corrosive applications stems from its molecular stability. It is one of the most non-reactive materials known, making it an ideal barrier against chemical attack.

What Makes PTFE Non-Reactive?

PTFE is a fluoropolymer with incredibly strong carbon-fluorine bonds. This stable molecular structure makes it inert to almost all chemicals, including aggressive acids, solvents, and bases. It simply does not react with the substances it comes into contact with.

How a Lining Protects the Valve

In many designs, the PTFE is not the structural body of the valve but a protective lining or a core component (like the ball and seats). The corrosive media only ever touches the inert PTFE surface, effectively shielding the valve's metal body from chemical attack and degradation.

Preserving Media Purity

Because PTFE is non-reactive, it does not leach substances into the process fluid. This ensures the purity of the media is maintained, which is critical in industries like pharmaceuticals, food processing, and high-purity chemical manufacturing.

Superior Sealing and Operational Advantages

Beyond its chemical resistance, PTFE's physical properties make it an excellent material for valve construction, ensuring both safety and reliability.

The Importance of a Tight Seal

PTFE provides effective, tight sealing with minimal torque. This is crucial when handling hazardous or corrosive media, as it prevents dangerous leaks that could harm personnel, damage equipment, and cause environmental issues.

The Self-Lubricating Advantage

PTFE has an extremely low coefficient of friction. This means the valve components move smoothly against each other without requiring any external lubrication. This eliminates a potential point of failure, as lubricants could be dissolved or degraded by corrosive media, leading to valve seizure or fluid contamination.

Reliable, Low-Effort Operation

The low-friction surface allows for fast, shock-free opening and closing, often with a simple quarter-turn. This reliable and low-torque operation makes manual control easy and is well-suited for automated systems.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its operational boundaries.

Temperature and Pressure Limits

PTFE has a lower maximum operating temperature and pressure rating compared to valves made entirely from exotic metal alloys. Exceeding these limits can cause the material to deform, compromising the seal.

Not Ideal for Abrasive Media

PTFE is a relatively soft material. While it resists chemical attack, it is not designed for abrasive media like slurries or fluids containing hard particulates, which can physically wear down the lining and sealing surfaces over time.

Potential for Material Creep

Under high, constant mechanical stress (a condition known as "creep"), PTFE can slowly deform. This must be considered in high-pressure applications where a constant load is applied to the valve seats.

Making the Right Choice for Your Application

Selecting a PTFE valve is an excellent decision when its unique properties align with your primary operational goals.

- If your primary focus is handling highly aggressive chemicals: The unmatched chemical inertness of PTFE is its most critical feature, providing robust protection where most other materials would fail.

- If your primary focus is maintaining absolute media purity: The non-reactive, non-leaching, and lubricant-free nature of PTFE construction is essential for your application.

- If your primary focus is operational safety and low maintenance: The combination of leak-proof sealing and a durable, self-lubricating design delivers a reliable, long-term solution.

Ultimately, leveraging PTFE's properties allows you to confidently control the most challenging fluids safely and effectively.

Summary Table:

| Key Property | Benefit in Corrosive Media |

|---|---|

| Chemical Inertness | Resists virtually all acids, solvents, and bases. |

| Self-Lubricating | Operates without external lubricants, preventing contamination. |

| Superior Sealing | Ensures leak-proof performance with minimal torque. |

| Media Purity | Non-reactive surface prevents leaching and preserves fluid integrity. |

Control your most aggressive chemicals with confidence.

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Our expertise in PTFE fabrication ensures your valves and fluid handling systems deliver unmatched reliability and purity for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a prototype or a high-volume order, our team is ready to provide a solution tailored to your specific corrosive media challenges.

Contact KINTEK today to discuss your application requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments