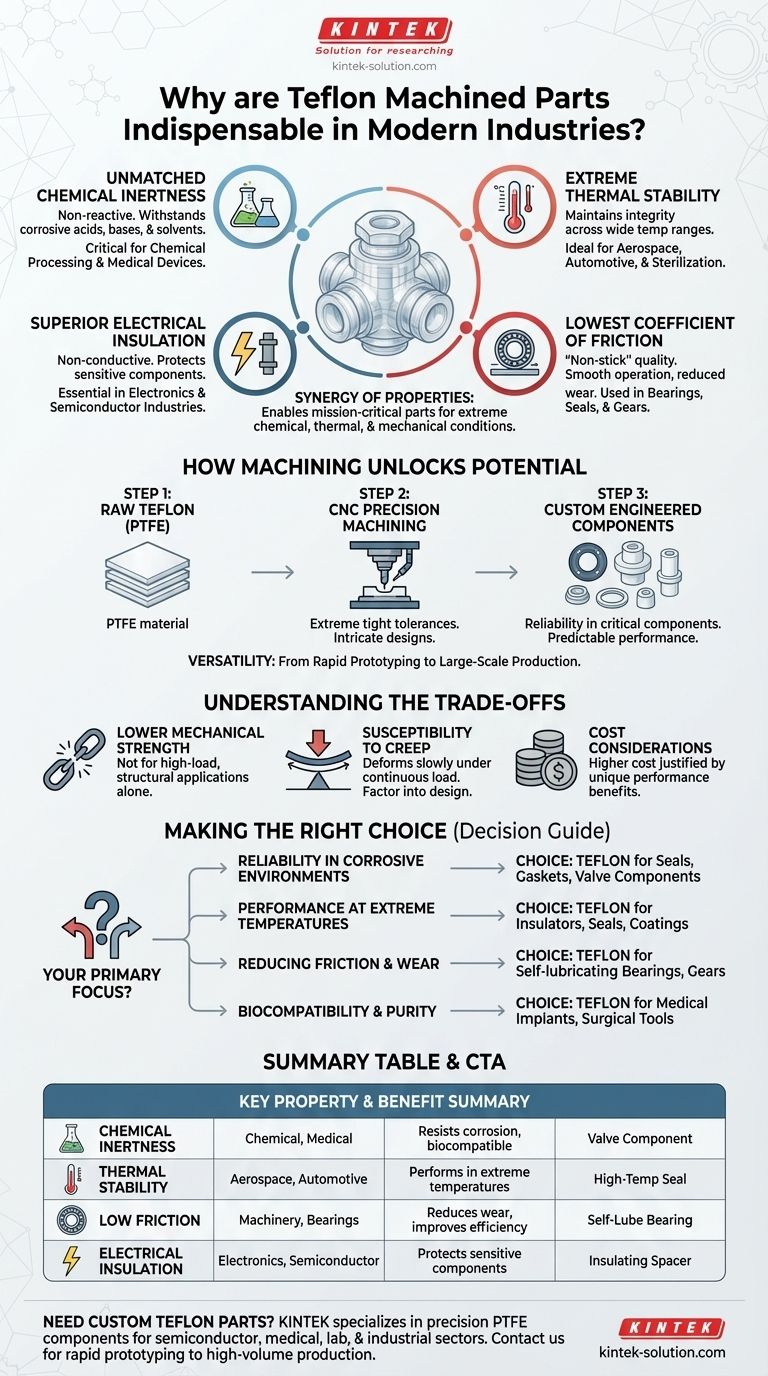

In short, Teflon machined parts are indispensable because they possess a unique combination of properties—chemical inertness, thermal stability, and low friction—that no other single material can match. This allows for the creation of high-performance, custom-engineered components that are critical for reliability and efficiency in the most demanding industrial environments, from aerospace to medical devices.

The true value of Teflon isn't just one of its famous properties, but the synergy of all of them. This synergy enables the design of mission-critical parts that can operate flawlessly in extreme chemical, thermal, and mechanical conditions where other materials would quickly fail.

The Core Properties That Define Teflon's Value

Teflon, a brand name for Polytetrafluoroethylene (PTFE), is not just one material but a family of fluoropolymers. Its utility comes from a set of inherent characteristics that make it a premier choice for specialized applications.

Unmatched Chemical Inertness

Teflon is famously non-reactive. It can withstand highly corrosive acids, bases, and solvents that would degrade metals and other plastics.

This property is non-negotiable in industries like chemical processing, where components are constantly exposed to harsh substances, and in medical devices, where biocompatibility is essential.

Extreme Thermal Stability

Teflon machined parts maintain their integrity and performance across a wide range of temperatures.

This makes them ideal for high-temperature applications in aerospace and automotive systems, as well as for components in food processing machinery that undergo frequent, high-heat sterilization.

The Lowest Coefficient of Friction

Known for its "non-stick" quality, Teflon has one of the lowest coefficients of friction of any solid material. This allows moving parts to operate smoothly with minimal resistance or wear.

This is the key reason it is used for bearings, seals, and gears, where reducing friction is critical to improving efficiency and extending the life of machinery.

Superior Electrical Insulation

Teflon is an excellent electrical insulator, meaning it does not conduct electricity.

This makes it an essential material in the electronics and semiconductor industries for creating insulators, spacers, and other components that protect sensitive electronics from electrical interference.

How Machining Unlocks Teflon's Potential

The raw material is only half the story. The ability to precisely machine Teflon into custom shapes is what makes it so versatile and valuable for modern engineering.

Precision for Complex Designs

CNC (Computer Numerical Control) machining allows for the creation of intricate parts with extremely tight tolerances.

This precision is vital for components like valve seats, complex gaskets, and custom insulators, where an exact fit is necessary for the entire system to function correctly.

Reliability in Critical Components

Machining ensures that each part meets exact design specifications, delivering consistent quality and reliability.

Whether it's a seal in an aircraft engine or a valve in a chemical plant, the part's performance is predictable and dependable, which is crucial in applications where failure is not an option.

Versatility from Prototyping to Production

The machining process is adaptable, supporting everything from rapid prototyping for new designs to large-scale production runs.

This flexibility allows engineers to test and refine concepts quickly before committing to mass production, accelerating innovation across industries.

Understanding the Trade-offs

While Teflon's properties are exceptional, it's crucial to understand its limitations to use it effectively. No material is perfect for every situation.

Lower Mechanical Strength

Compared to metals or some engineering plastics, PTFE has lower tensile strength and is softer. It is not suitable for high-load, structural applications on its own.

Susceptibility to Creep

Under a continuous load, Teflon can slowly deform over time, a phenomenon known as "creep." This must be factored into the design of components that will be under constant pressure.

Cost Considerations

Custom-machined Teflon parts are often more expensive than components made from more common materials. The cost is justified by its unique performance benefits in specialized, demanding environments.

Making the Right Choice for Your Application

Selecting Teflon should be a deliberate decision based on the specific operational challenges you need to solve.

- If your primary focus is reliability in corrosive environments: Teflon's chemical inertness makes it the definitive choice for seals, gaskets, and valve components in chemical and food processing.

- If your primary focus is performance at extreme temperatures: Its thermal stability is essential for insulators, seals, and coatings in aerospace, automotive, and industrial machinery.

- If your primary focus is reducing friction and wear: Its low-friction surface is ideal for creating self-lubricating bearings, gears, and non-stick surfaces in mechanical systems.

- If your primary focus is biocompatibility and purity: Its non-reactive nature is critical for medical implants, surgical tools, and pharmaceutical manufacturing equipment.

By leveraging Teflon's distinct advantages, engineers can solve problems and enhance performance in ways that would be impossible with conventional materials.

Summary Table:

| Key Property | Industry Application | Key Benefit |

|---|---|---|

| Chemical Inertness | Chemical Processing, Medical | Resists corrosive substances, biocompatible |

| Thermal Stability | Aerospace, Automotive | Performs in extreme temperatures |

| Low Friction | Machinery, Bearings | Reduces wear, improves efficiency |

| Electrical Insulation | Electronics, Semiconductor | Protects sensitive components |

Need custom Teflon (PTFE) parts for your demanding application? KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. From rapid prototyping to high-volume production, we ensure reliability and performance in extreme conditions. Contact us today to discuss your custom fabrication needs and see how our expertise can enhance your project's success!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers