Fundamentally, PTFE slide bearings are advantageous for highway bridges because they combine an extremely low coefficient of friction with high load capacity and near-zero maintenance requirements. This unique set of properties allows them to safely accommodate the constant, subtle movements of a bridge—caused by temperature changes and traffic—without transferring destructive stress into the support structure.

The core value of a PTFE slide bearing in a bridge is its ability to decouple the superstructure (the deck) from the substructure (the piers). It allows the bridge deck to expand and contract freely, preventing the buildup of immense internal forces that could otherwise damage the entire structure.

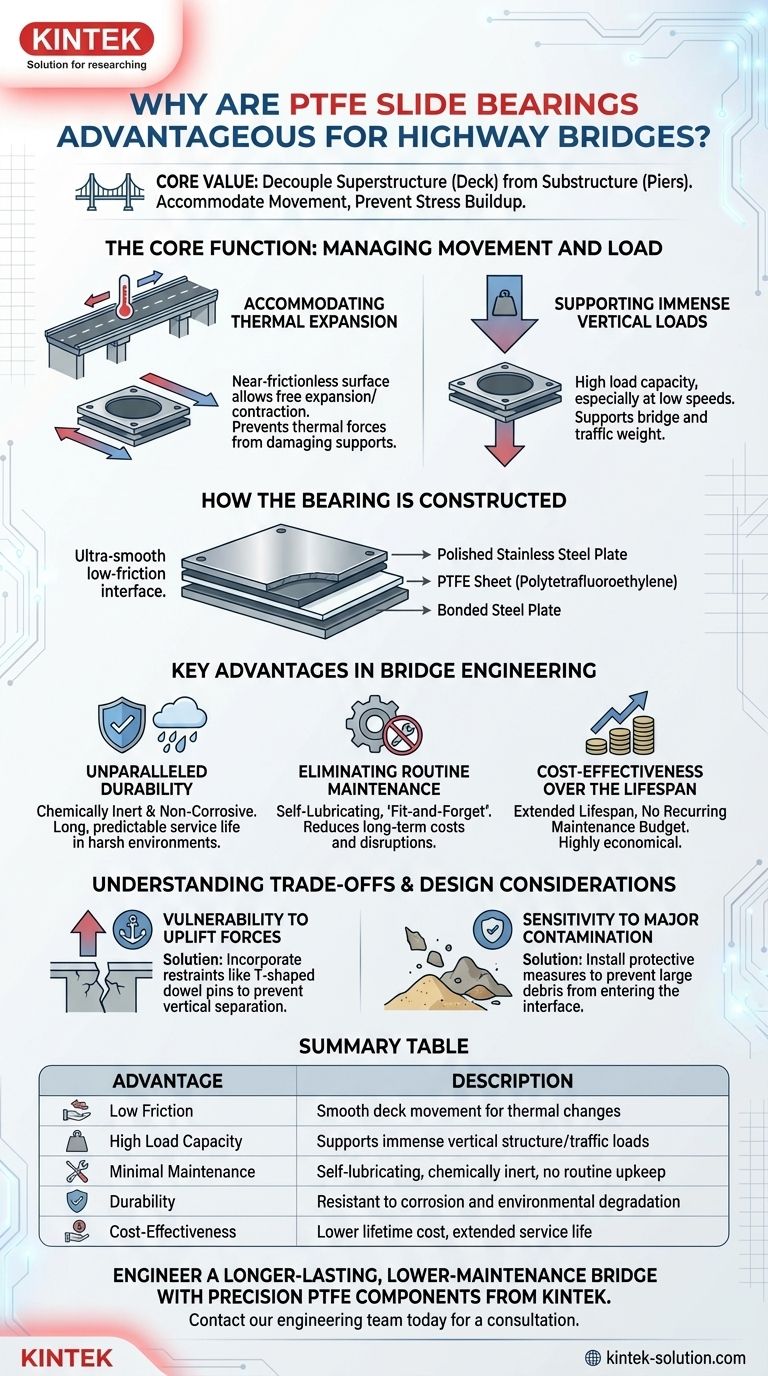

The Core Function: Managing Movement and Load

A bridge appears static, but it is in constant, slow motion. A bearing's primary job is to manage this movement while supporting the colossal weight of the structure and the traffic it carries.

Accommodating Thermal Expansion

A bridge deck expands in the heat and contracts in the cold. Over a long span, this movement can be several inches.

PTFE slide bearings provide a near-frictionless surface, allowing the bridge deck to slide back and forth smoothly. This prevents the thermal forces from pushing and pulling on the support piers, which could lead to cracking and failure over time.

Supporting Immense Vertical Loads

While allowing for horizontal movement, the bearing must simultaneously support the immense and constant downward force (the vertical load) of the bridge deck and traffic.

PTFE is engineered to handle this high load capacity, especially at the very low speeds associated with thermal expansion, making it a perfect material for this application.

How the Bearing is Constructed

The typical design is simple yet effective. It consists of a polished stainless steel plate that slides over a sheet of PTFE (polytetrafluoroethylene), which is bonded to another steel plate.

The ultra-smooth surfaces sliding against each other create the low-friction interface, permitting movement in longitudinal and transverse directions unless specifically restrained by guides.

Key Advantages in Bridge Engineering

Beyond its core function, PTFE offers a range of properties that make it the modern standard for most highway bridge applications, especially when compared to older mechanical systems like roller bearings.

Unparalleled Durability

Bridge bearings are exposed to harsh environmental conditions, including rain, de-icing salts, and pollutants.

PTFE is chemically inert and non-corrosive, meaning it does not degrade from chemical exposure or galvanic corrosion. This ensures a long, predictable service life.

Eliminating Routine Maintenance

Older bearing types, like rockers or rollers, require regular cleaning and lubrication to function correctly and prevent seizure from rust.

PTFE is self-lubricating and inherently resistant to dirt and debris. This "fit-and-forget" characteristic dramatically reduces the long-term maintenance costs and traffic disruptions associated with bridge upkeep.

Cost-Effectiveness Over the Lifespan

While the initial component cost is a factor, the true economic advantage of PTFE bearings comes from their longevity and lack of maintenance needs.

The extended lifespan and elimination of a recurring maintenance budget make them a highly cost-effective solution for the decades-long operational life of a bridge.

Understanding the Trade-offs and Design Considerations

No engineering solution is without limitations. Objectivity requires understanding where a standard PTFE slide bearing is insufficient on its own and how engineers mitigate these issues.

Vulnerability to Uplift Forces

PTFE slide bearings are designed primarily to handle vertical (compressive) and horizontal (shear) loads. They are not inherently designed to resist uplift forces, such as those from high winds or certain traffic load characteristics.

To counteract this, engineers incorporate restraints like T-shaped dowel pins or brackets that anchor the superstructure to the substructure, preventing any vertical separation while still allowing free horizontal movement.

Sensitivity to Major Contamination

While PTFE is resistant to absorbing small dirt particles, the sliding surfaces must be protected from significant debris like sand or gravel.

The bearing is typically installed with protective measures to prevent large contaminants from entering the sliding interface, as this could score the stainless steel plate and increase friction.

Making the Right Choice for Your Goal

Selecting and designing a bearing system depends entirely on the specific forces at play in a given bridge design.

- If your primary focus is longevity and minimal maintenance: PTFE bearings are the default choice for most standard highway bridges due to their self-lubricating nature and superior corrosion resistance.

- If your bridge experiences significant thermal movement: The exceptionally low coefficient of friction in PTFE is critical for preventing the transfer of damaging stress to piers and foundations.

- If you are designing for complex forces like uplift or braking: A standard PTFE slide bearing must be augmented with guide rails or mechanical restraints to safely manage these additional loads.

By effectively isolating the bridge deck from its foundation, PTFE slide bearings are a foundational component of modern, durable, and cost-effective bridge design.

Summary Table:

| Advantage | Description |

|---|---|

| Low Friction | Allows smooth bridge deck movement from thermal expansion/contraction. |

| High Load Capacity | Supports immense vertical loads from the structure and traffic. |

| Minimal Maintenance | Self-lubricating and chemically inert, eliminating routine upkeep. |

| Durability | Resistant to corrosion, chemicals, and environmental degradation. |

| Cost-Effectiveness | Lower lifetime cost due to extended service life and no maintenance budget. |

Engineer a longer-lasting, lower-maintenance bridge with precision PTFE components from KINTEK.

For over 50 years, KINTEK has been a trusted partner to the civil engineering and infrastructure industries. We specialize in the custom fabrication of high-performance PTFE components, including seals, liners, and custom bearings, tailored to meet the rigorous demands of highway bridge applications.

Our expertise ensures your components deliver:

- Unmatched Durability: Superior material integrity for decades of reliable service.

- Precision Engineering: Exact specifications to handle specific load and movement requirements.

- Cost-Effective Solutions: From prototypes to high-volume orders, we help control project lifecycle costs.

Ready to specify the right PTFE solution for your next project? Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments