The reason is the material itself. PTFE processing machines derive their exceptional corrosion resistance directly from their primary construction material: Polytetrafluoroethylene (PTFE). This fluoropolymer is one of the most chemically inert substances known, allowing equipment built from it to operate reliably in harsh environments involving acids, bases, and a wide range of organic solvents.

The source of PTFE's resilience isn't a coating or a treatment; it is a fundamental property of its molecular structure. The incredibly strong bond between its carbon and fluorine atoms creates a non-reactive shield, making the material itself a fortress against chemical attack.

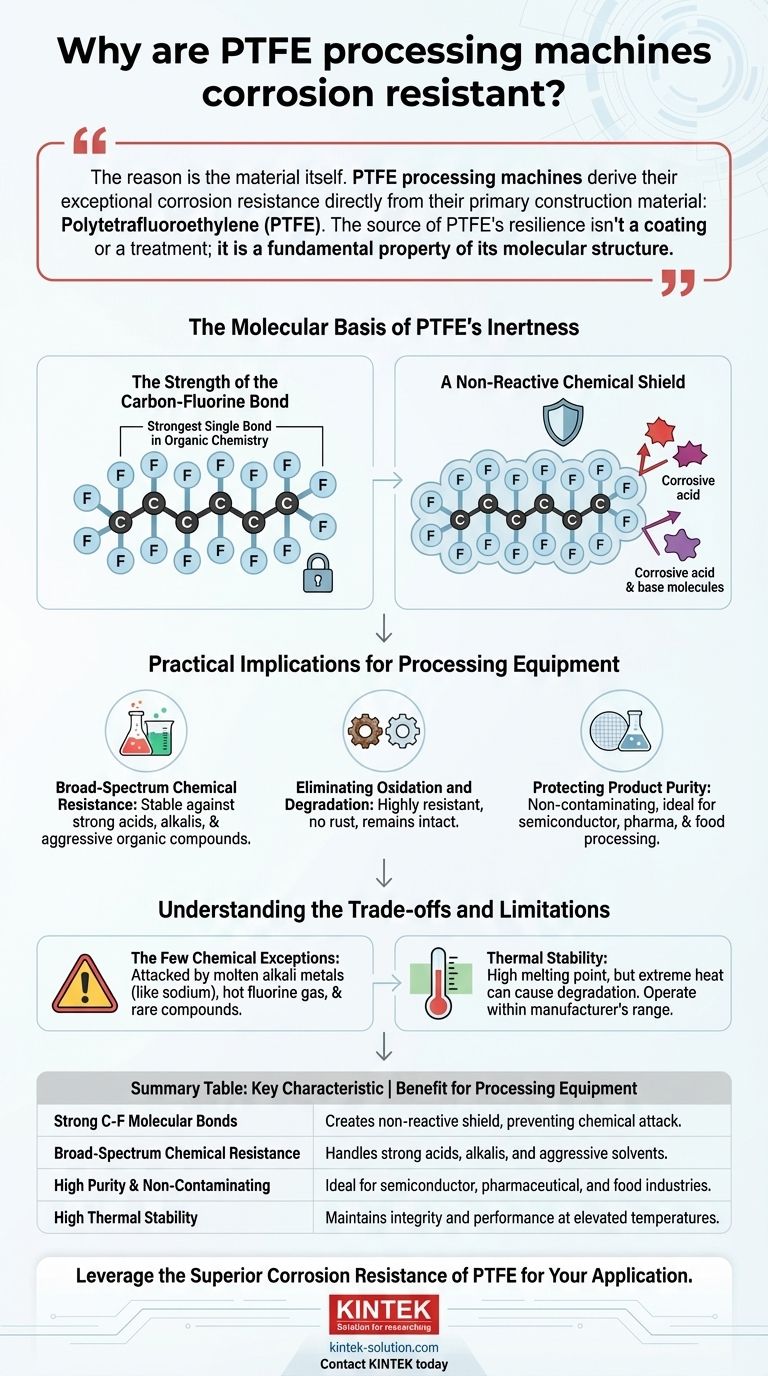

The Molecular Basis of PTFE's Inertness

To understand why PTFE machines don't corrode, we must look at their chemical makeup. The material's properties are not accidental; they are a direct result of its atomic structure.

The Strength of the Carbon-Fluorine Bond

At its core, PTFE consists of a long chain of carbon atoms, but each carbon is completely surrounded and protected by fluorine atoms.

The bond between a carbon atom and a fluorine atom (C-F) is one of the strongest single bonds in organic chemistry. This immense strength makes it extremely difficult for other chemicals to break the bond and initiate a reaction.

A Non-Reactive Chemical Shield

The fluorine atoms effectively form a tight, stable, and non-porous sheath around the vulnerable carbon backbone.

This molecular shield prevents corrosive substances from finding a point of attack. The machine's surfaces that come into contact with fluids are, on a molecular level, almost entirely non-reactive.

Practical Implications for Processing Equipment

This fundamental chemical stability translates directly into superior performance and longevity for machines operating in corrosive settings.

Broad-Spectrum Chemical Resistance

PTFE is stable when exposed to nearly all industrial chemicals and solvents. This includes strong acids, alkalis, and aggressive organic compounds that would quickly degrade metals and other plastics.

Eliminating Oxidation and Degradation

Unlike many materials that rust or degrade through oxidation, PTFE is highly resistant to this process. This allows for continuous exposure to chemicals without the material becoming brittle or losing its integrity.

Protecting Product Purity

Because PTFE is so inert, it does not leach chemicals or contaminate the media it is processing. This is critical in high-purity applications found in the semiconductor, pharmaceutical, and food processing industries.

Understanding the Trade-offs and Limitations

While its resistance is remarkable, no material is perfect. Acknowledging the specific, limited exceptions is key to using PTFE equipment correctly and safely.

The Few Chemical Exceptions

PTFE's inertness is near-universal, but it can be attacked by a very small number of highly reactive substances.

These include molten alkali metals (like sodium), hot fluorine gas, and a few other rare fluorine compounds like chlorine trifluoride. For the vast majority of industrial applications, these exceptions are not a factor.

Thermal Stability

PTFE has a high melting point and can operate at high temperatures without losing its chemical resistance. However, it's important to operate within the manufacturer's specified temperature range, as extreme heat can eventually cause degradation.

Making the Right Choice for Your Application

Understanding the source of PTFE's corrosion resistance allows you to deploy it strategically where it offers the most value.

- If your primary focus is handling aggressive chemicals: PTFE equipment is often the default choice for reliability and safety with strong acids, bases, and solvents.

- If your primary focus is product purity: The inert nature of PTFE ensures that the material being processed remains uncontaminated by the equipment itself.

- If you are working with molten alkali metals or hot fluorine gas: You must seek an alternative material, as this is one of the few environments where PTFE is not suitable.

Ultimately, choosing a PTFE processing machine is a decision to leverage a material whose fundamental chemistry provides a superior defense against corrosion.

Summary Table:

| Key Characteristic | Benefit for Processing Equipment |

|---|---|

| Strong C-F Molecular Bonds | Creates a non-reactive shield, preventing chemical attack. |

| Broad-Spectrum Chemical Resistance | Handles strong acids, alkalis, and aggressive solvents. |

| High Purity & Non-Contaminating | Ideal for semiconductor, pharmaceutical, and food industries. |

| High Thermal Stability | Maintains integrity and performance at elevated temperatures. |

Leverage the Superior Corrosion Resistance of PTFE for Your Application

Do you work with aggressive chemicals or require the highest product purity? The exceptional inertness of PTFE, as detailed above, is the key to reliable and safe processing.

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical need for equipment that can withstand harsh environments without compromising purity or performance.

Whether you need a standard component or a custom-fabricated solution from prototype to high-volume production, our expertise ensures you get the corrosion resistance your process demands.

Contact KINTEK today to discuss how our PTFE solutions can protect your process and enhance your product quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech