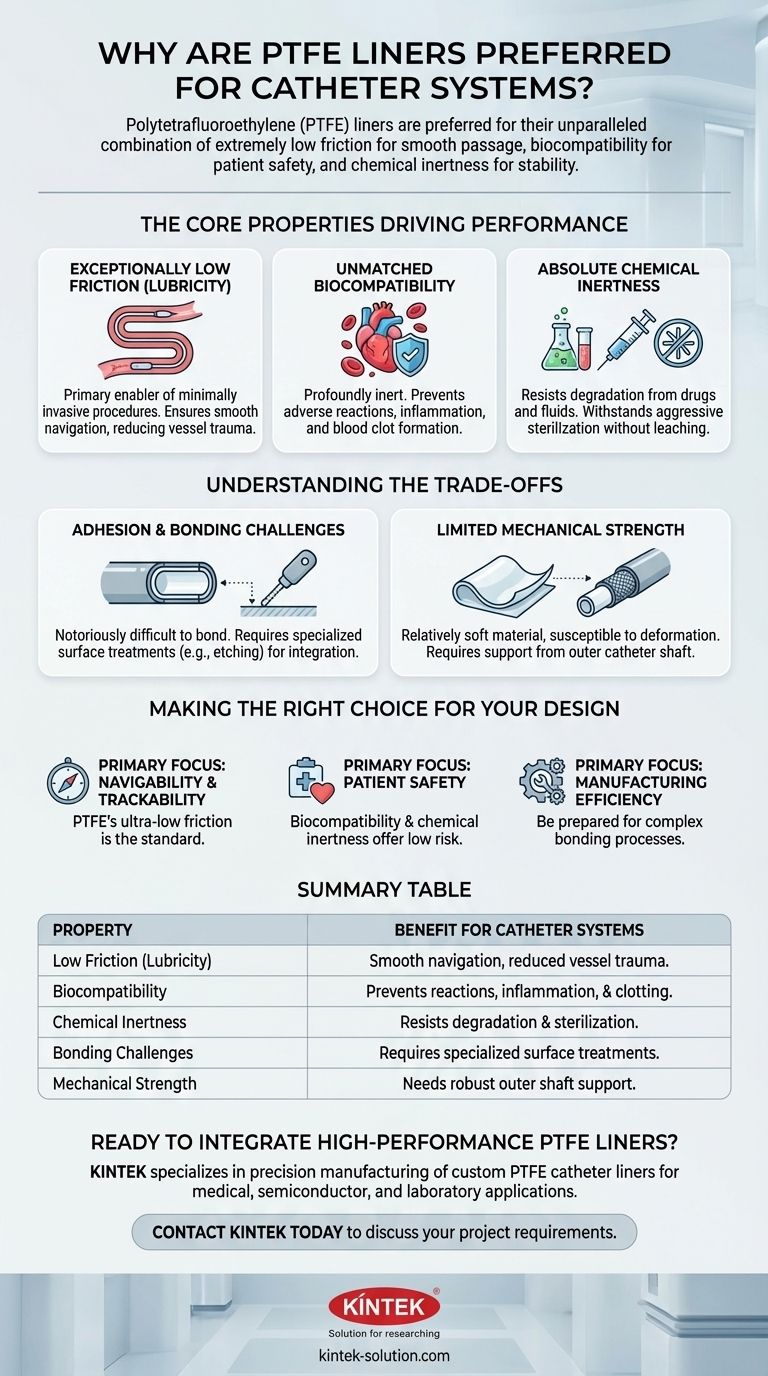

In short, Polytetrafluoroethylene (PTFE) liners are preferred because they possess an unparalleled combination of properties essential for medical devices that navigate the human body. Their extremely low friction allows for smooth passage through complex vasculatures, their biocompatibility prevents adverse reactions with tissues and blood, and their chemical inertness ensures they do not react with drugs or bodily fluids.

The core reason for PTFE's dominance is not just one of its properties, but its unique ability to deliver high performance in three critical, and often competing, areas simultaneously: mechanical lubricity, biological safety, and chemical stability.

The Core Properties Driving Performance

To understand why PTFE is the benchmark material, we must analyze how its fundamental characteristics directly translate into clinical performance and patient safety.

Exceptionally Low Friction (Lubricity)

PTFE has one of the lowest coefficients of friction of any solid material, a property often described as lubricity.

This is not merely a minor benefit; it is the primary enabler of modern minimally invasive procedures. This extreme slipperiness ensures the catheter can be advanced and navigated through tortuous blood vessels with minimal force.

This directly reduces the risk of damaging the delicate inner lining of arteries and veins, a critical factor for procedural success and patient recovery.

Unmatched Biocompatibility

A material is biocompatible if it does not provoke a harmful response when introduced to the body.

PTFE is profoundly inert biologically. It does not cause irritation, inflammation, or trigger the body's immune system.

Crucially, its surface resists the formation of blood clots (thrombosis), which is a major risk when foreign objects are placed inside the bloodstream. This property is fundamental to patient safety.

Absolute Chemical Inertness

Catheter systems are exposed to a wide range of substances, including saline, contrast agents for imaging, and therapeutic drugs.

PTFE's chemical inertness means it will not degrade or react when exposed to these chemicals. This guarantees two things: the liner's structural integrity remains intact, and no harmful substances are leached from the material into the patient's system.

This stability also means it can withstand aggressive sterilization methods, ensuring the device is sterile without compromising its material properties.

Understanding the Trade-offs

While PTFE's benefits are significant, no material is perfect. A thorough technical assessment requires acknowledging its engineering challenges.

Adhesion and Bonding Challenges

The same non-stick property that makes PTFE so valuable also makes it notoriously difficult to bond to other materials.

The outer layers of a catheter (often made of nylon, Pebax, or braided wire) require a strong bond to the inner PTFE liner to function as a cohesive unit.

Engineers must employ specialized surface treatments, such as sodium naphthalene etching, to create a bondable surface on the PTFE liner, adding complexity and cost to the manufacturing process.

Limited Mechanical Strength

Compared to other engineering polymers, PTFE is a relatively soft material with lower tensile strength and resistance to abrasion.

It is susceptible to "creep" or cold flow, meaning it can deform over time under sustained pressure.

For this reason, PTFE is almost always used as a liner supported by a more robust outer catheter shaft, which provides the necessary pushability, torque response, and kink resistance.

Making the Right Choice for Your Design

The selection of PTFE is a strategic decision based on balancing performance requirements with manufacturing realities.

- If your primary focus is navigability and trackability: PTFE's ultra-low coefficient of friction is the single most important property and remains the industry standard.

- If your primary focus is patient safety: The combination of proven biocompatibility and chemical inertness makes PTFE a low-risk, reliable choice for any device with blood or tissue contact.

- If your primary focus is manufacturing efficiency: Be prepared to invest in sophisticated surface treatment and bonding processes to reliably integrate the PTFE liner into your final catheter assembly.

Ultimately, PTFE remains the preferred choice for catheter liners because its benefits for clinical performance and patient safety far outweigh its manufacturing complexities.

Summary Table:

| Property | Benefit for Catheter Systems |

|---|---|

| Low Friction (Lubricity) | Enables smooth navigation through complex vasculature with minimal force, reducing vessel trauma. |

| Biocompatibility | Prevents adverse reactions, inflammation, and blood clot formation, ensuring patient safety. |

| Chemical Inertness | Resists degradation from drugs and fluids, and withstands aggressive sterilization methods. |

| Bonding Challenges | Requires specialized surface treatments for integration, adding complexity to manufacturing. |

| Mechanical Strength | Needs a robust outer shaft for support, as PTFE is soft and susceptible to deformation over time. |

Ready to integrate high-performance PTFE liners into your medical device designs?

KINTEK specializes in the precision manufacturing of PTFE components, including custom catheter liners. We understand the critical balance of lubricity, biocompatibility, and manufacturability required for advanced medical applications in the semiconductor, medical, and laboratory industries.

We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet the highest standards for performance and patient safety.

Contact KINTEK today to discuss your project requirements and leverage our expertise in advanced polymer solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers