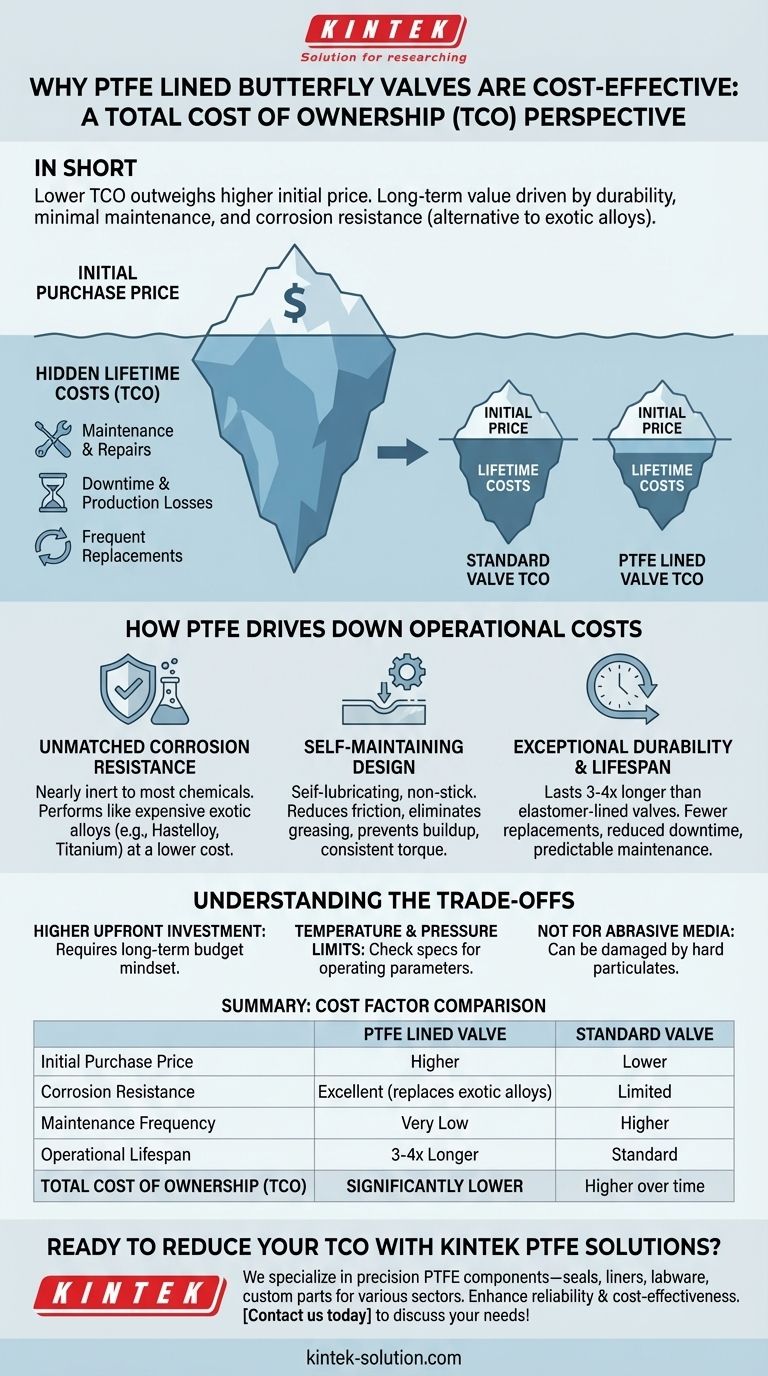

In short, PTFE lined butterfly valves are considered cost-effective because their significantly lower total cost of ownership (TCO) far outweighs their higher initial purchase price. This long-term value is driven by exceptional durability, minimal maintenance requirements, and the ability to handle corrosive substances that would otherwise require valves made from far more expensive exotic alloys.

The core insight is that viewing a PTFE lined valve's cost is a mistake. It should be viewed as an investment. This investment pays for itself over its lifecycle by drastically reducing maintenance costs, preventing costly production downtime, and eliminating the need for high-cost specialty metal valves in aggressive applications.

Why TCO Matters More Than Purchase Price

The true cost of any industrial component isn't what you pay for it on day one. It's the sum of all expenses incurred over its operational life.

Shifting Focus from Initial Outlay

A standard rubber-lined valve may appear cheaper on an invoice, but this price tag ignores the hidden costs of maintenance, repair, and eventual replacement. A higher upfront cost for a PTFE-lined valve is a strategic decision to minimize these future expenses.

Factoring in Lifetime Costs

Total Cost of Ownership (TCO) includes the initial purchase plus all operational and maintenance costs. For valves, this encompasses expenses related to repair parts, labor for maintenance, production losses from downtime, and the frequency of full replacement.

How PTFE Liners Drive Down Operational Costs

The unique properties of Polytetrafluoroethylene (PTFE) are directly responsible for the valve's long-term financial benefits. These features work together to create a highly reliable, low-maintenance component.

Unmatched Corrosion Resistance

This is arguably the single greatest cost-saving factor. PTFE is nearly inert to a vast range of chemicals, including strong acids, alkalis, and oxidizers.

This allows a PTFE-lined ductile iron valve to perform the same job as a valve constructed entirely from an expensive exotic alloy like Hastelloy or Titanium. The cost difference in this scenario is substantial, making the PTFE option dramatically more economical from the start.

A Self-Maintaining Design

PTFE surfaces are inherently self-lubricating and have an extremely low coefficient of friction, often compared to wet ice on wet ice. This means the valve disc moves smoothly without requiring external lubrication or grease, eliminating a common maintenance task.

Furthermore, the material is non-stick, which prevents media from building up on the valve's internal surfaces. This ensures consistent performance, reduces cleaning requirements, and maintains low, predictable torque, which in turn reduces wear on the actuator.

Exceptional Durability and Lifespan

PTFE lined valves have an outstanding operational life, often lasting three to four times longer than standard elastomer-lined valves in the same service.

This extended lifespan directly translates to cost savings. You purchase and install new valves less frequently, which reduces not only material costs but also the significant labor and production downtime associated with valve replacement. Fewer replacements also mean fewer emergency repairs and a more predictable maintenance budget.

Understanding the Trade-offs

While highly effective, PTFE lined valves are not a universal solution. Objectivity requires acknowledging their limitations.

The Higher Upfront Investment

As the initial question implies, the purchase price is higher than that of valves with common rubber liners like EPDM or NBR (Buna-N). This requires a budget that prioritizes long-term value over immediate cost savings.

Temperature and Pressure Limitations

PTFE has a more restricted operating temperature range compared to metal-seated valves. High temperatures can cause the material to creep or deform, potentially compromising the seal. Always verify the valve's specifications against your system's operating parameters.

Not Ideal for Abrasive Media

PTFE is a relatively soft material. It excels in corrosive chemical applications but can be damaged by abrasive slurries containing hard particulates. In such cases, a hard rubber or ceramic-lined valve may be a more durable choice.

Making the Right Choice for Your Application

Selecting the right valve liner is about aligning the material's strengths with your primary operational goal.

- If your primary focus is handling corrosive media: The PTFE lined valve is a highly cost-effective alternative to expensive exotic alloy valves.

- If your primary focus is minimizing maintenance and downtime: The self-lubricating, non-stick, and durable nature of PTFE provides exceptional long-term reliability and operational stability.

- If your primary focus is the lowest possible initial cost for a non-corrosive service: A standard valve with an EPDM or NBR liner may be sufficient, but understand the potential for higher lifetime costs.

By evaluating the valve's performance and cost over its entire lifecycle, you can make a financially sound decision that enhances system reliability.

Summary Table:

| Cost Factor | PTFE Lined Valve | Standard Valve |

|---|---|---|

| Initial Purchase Price | Higher | Lower |

| Corrosion Resistance | Excellent (replaces exotic alloys) | Limited |

| Maintenance Frequency | Very Low | Higher |

| Operational Lifespan | 3-4x Longer | Standard |

| Total Cost of Ownership (TCO) | Significantly Lower | Higher over time |

Ready to reduce your total cost of ownership with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom-fabricated parts—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get durable, corrosion-resistant solutions that minimize maintenance and downtime, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your system's reliability and cost-effectiveness!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining