In short, PTFE heat press sheets are essential because they act as a non-stick, heat-resistant barrier. This single component is responsible for protecting your garment from scorching, preventing ink and vinyl from sticking to your equipment, and ensuring a clean, professional-quality transfer every time.

A PTFE sheet is not merely an accessory; it is a fundamental safeguard in heat transfer printing. It protects the two most critical assets in the process: the product you are creating and the equipment you are using to create it.

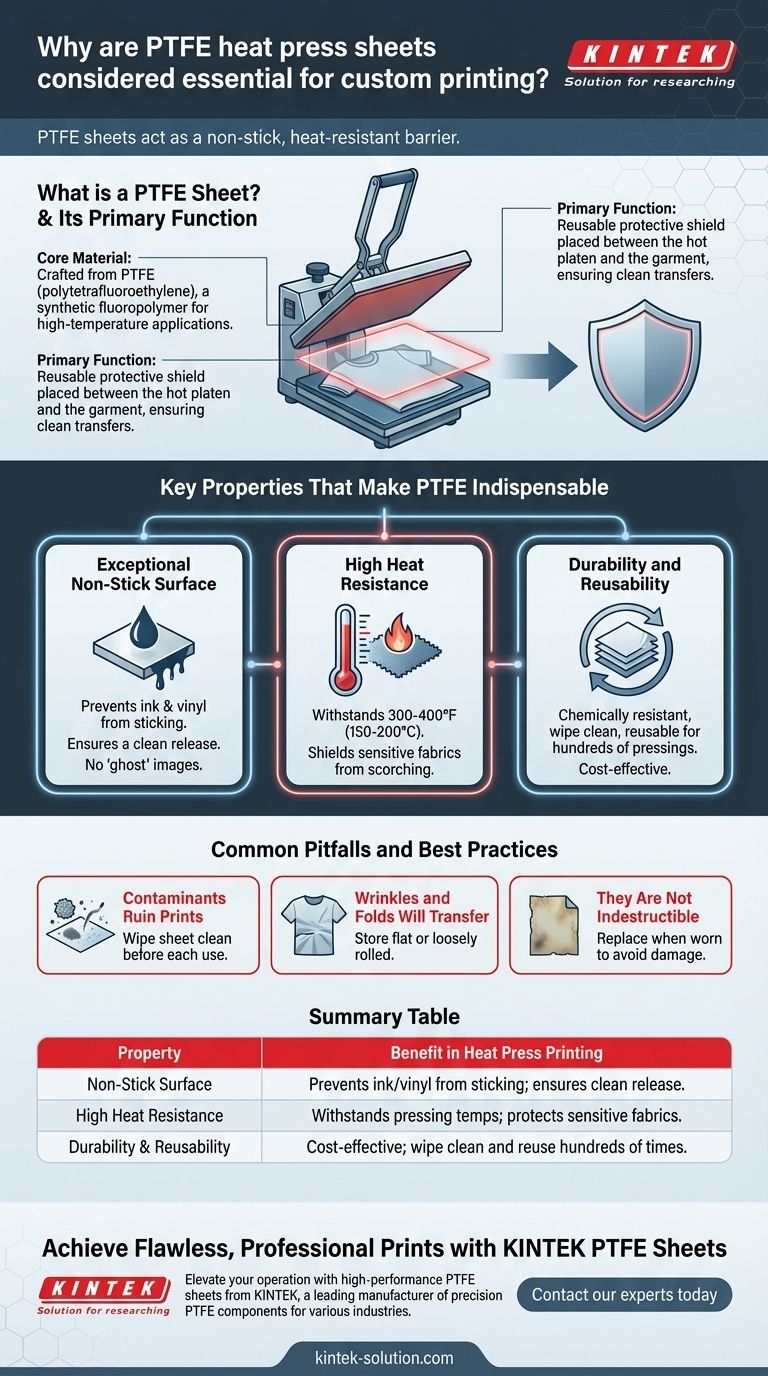

What is a PTFE Sheet?

PTFE sheets, commonly known by the brand name Teflon sheets, serve as a protective layer during the application of heat and pressure in custom printing.

The Core Material

These sheets are crafted from PTFE (polytetrafluoroethylene), a synthetic fluoropolymer known for its extreme properties. Its unique molecular structure gives it characteristics that are ideal for high-temperature applications.

The Primary Function

In any heat press process, whether using vinyl, sublimation ink, or other transfers, the PTFE sheet acts as a reusable protective shield. It is placed between the hot upper platen of the press and your garment or substrate.

Key Properties That Make PTFE Indispensable

The value of a PTFE sheet comes from a combination of three critical physical properties that directly solve common heat pressing problems.

Exceptional Non-Stick Surface

The most important attribute is that virtually nothing sticks to it. This prevents melted adhesives, heat transfer vinyl (HTV), and sublimation inks from transferring onto the heat platen, ensuring a clean release of the design onto the garment.

A clean platen is critical for preventing "ghost" images or residue from ruining subsequent projects.

High Heat Resistance

PTFE sheets can withstand the high temperatures required for heat transfer (typically 300-400°F or 150-200°C) without melting or degrading. This allows them to distribute heat evenly while shielding sensitive fabrics from direct, intense contact that could cause scorching or discoloration.

Durability and Reusability

These sheets are not single-use items. Their durable and chemically resistant nature means they can be wiped clean and reused for hundreds or even thousands of pressings, making them a highly cost-effective tool for any printing operation.

Common Pitfalls and Best Practices

While essential, the effectiveness of a PTFE sheet depends entirely on its condition and proper use. Ignoring this can lead to flawed results.

Contaminants Ruin Prints

Any dust, stray fibers, or ink residue left on the sheet can be permanently pressed into your next garment. Always wipe the sheet clean before each use to ensure a flawless surface.

Wrinkles and Folds Will Transfer

A permanent crease, fold, or wrinkle in the PTFE sheet will transfer its pattern onto your final design, leaving a visible impression. Store your sheets flat or loosely rolled to maintain a perfectly smooth surface.

They Are Not Indestructible

Over time and with repeated use, the non-stick coating can wear down or the sheet can become discolored. A worn-out sheet loses its protective qualities and should be replaced immediately to avoid damaging your products.

Making the Right Choice for Your Goal

Using a PTFE sheet is a non-negotiable step for achieving reliable, high-quality results in custom printing.

- If your primary focus is professional quality and consistency: A PTFE sheet is essential for preventing ink bleed and ensuring crisp, clean designs on every single item.

- If your primary focus is protecting your equipment: This sheet is the single best defense for keeping your heat press platen free of baked-on residue that is difficult to clean and can ruin future jobs.

- If your primary focus is preventing costly errors: Using a PTFE sheet is the most effective insurance against scorching expensive garments or substrates, saving you money on wasted materials.

Ultimately, this simple tool elevates your work from amateur to professional by introducing control and protection into the heat transfer process.

Summary Table:

| Property | Benefit in Heat Press Printing |

|---|---|

| Non-Stick Surface | Prevents ink/vinyl from sticking to the platen; ensures clean release. |

| High Heat Resistance | Withstands pressing temps (300-400°F); protects sensitive fabrics from scorching. |

| Durability & Reusability | Cost-effective; can be wiped clean and reused for hundreds of pressings. |

Achieve Flawless, Professional Prints with KINTEK PTFE Sheets

Elevate your custom printing operation with high-performance PTFE heat press sheets from KINTEK. We are a leading manufacturer of precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get a PTFE sheet that delivers superior non-stick performance, exceptional heat resistance, and unmatched durability—protecting both your valuable equipment and your finished products.

Whether you need a reliable prototype or a high-volume order, KINTEK prioritizes precision production to meet your exact specifications.

Protect your investment and ensure print perfection. Contact our experts today to discuss your PTFE sheet needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What environmental concerns are associated with Teflon packing? The Hidden Cost of a Non-Biodegradable Seal

- What are the advantages of using PTFE seals in fluid power applications? Solve Extreme Performance Challenges

- What environmental benefits do PTFE expansion joints provide? Achieve Sustainability and Compliance

- What are the key advantages of PTFE oil seals over conventional oil seals? Superior Performance for Extreme Conditions

- How does PTFE's high-temperature tolerance benefit shaft seals? Ensure Reliability in Extreme Heat

- How can virgin PTFE be prepared for bonding? Achieve a Permanent, High-Strength Bond

- Which industries benefit from Teflon machined parts? Achieve Peak Performance in Demanding Applications

- How is PTFE used in structural sliding bearings? Enable Smooth Movement Under Immense Loads