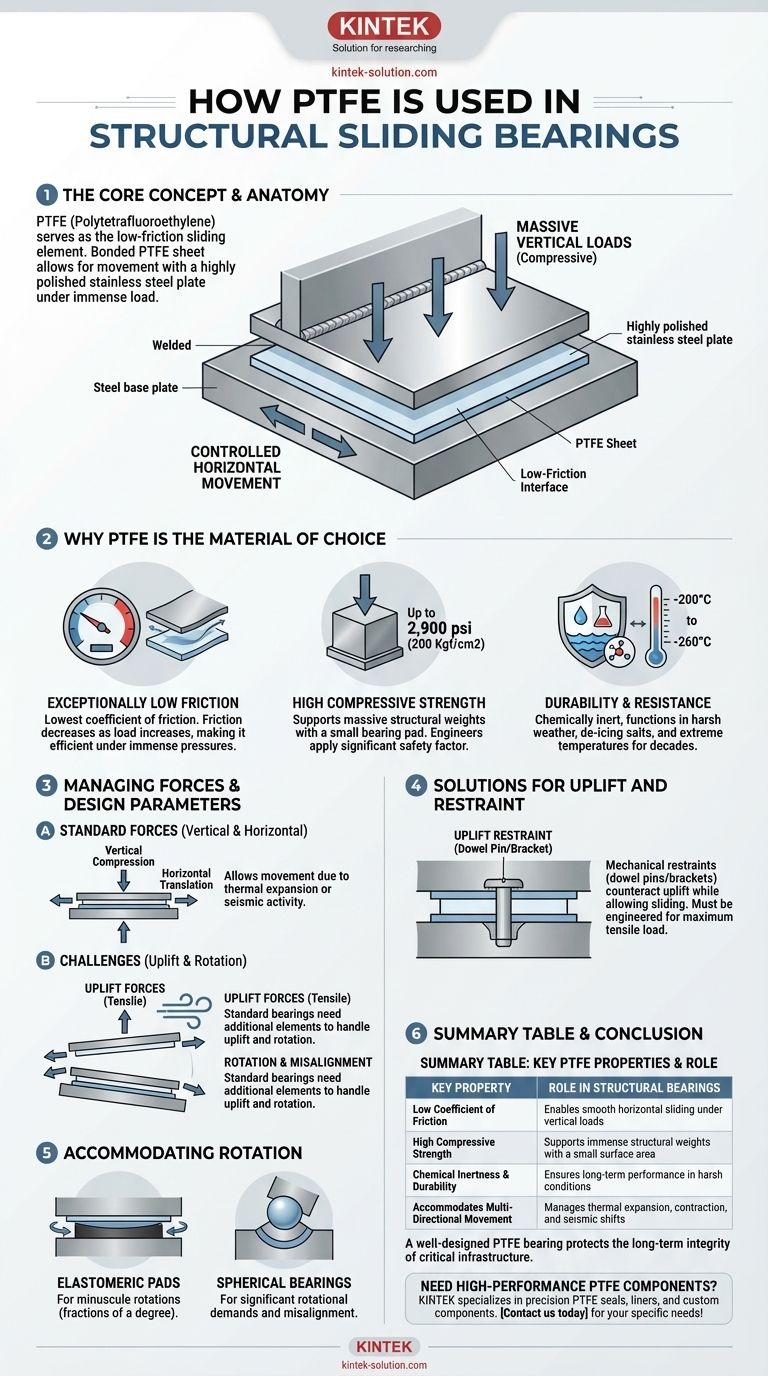

In structural sliding bearings, Polytetrafluoroethylene (PTFE) serves as the core low-friction sliding element. A sheet of virgin or filled PTFE is bonded to a steel base plate, creating a durable surface. A highly polished stainless steel plate is then placed on the PTFE, and this interface is what supports immense vertical loads while allowing for controlled, smooth horizontal movement from forces like thermal expansion or seismic activity.

The fundamental purpose of using PTFE in structural bearings is to exploit its uniquely low coefficient of friction and high compressive strength. This combination allows massive structures like bridges and buildings to safely expand, contract, and shift without generating destructive internal stresses.

The Anatomy of a PTFE Sliding Bearing

A PTFE bearing is a deceptively simple assembly designed for a critical task. It is a composite system where each part plays a specific role in managing structural loads and movements.

The Core Sliding Interface

The heart of the bearing is the contact point between two materials: the PTFE sheet and the polished stainless steel plate. The PTFE is securely bonded to a lower steel backing plate, while the stainless steel plate is welded to the upper structural element. The entire vertical load of the structure is transferred through this small, low-friction interface.

How it Manages Forces

This assembly is designed to perform two jobs simultaneously. It transmits massive vertical (compressive) loads from the structure to the foundation while allowing for horizontal (translational) movement in one or more directions. This movement is essential for accommodating changes in the structure's length due to temperature fluctuations.

Why PTFE is the Material of Choice

Engineers select materials based on a specific balance of properties. PTFE's unique combination of characteristics makes it almost perfectly suited for high-load structural sliding applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. When paired with polished stainless steel, this coefficient is exceptionally low. Critically, the friction often decreases as the load increases, making it even more efficient under the immense pressures of a large structure.

High Compressive Strength

Pure PTFE can withstand significant compressive pressures, often cited up to 2,900 psi (200 Kgf/cm2). This allows a relatively small bearing pad to support a massive load. In practice, engineers apply a significant safety factor to prevent long-term creep and ensure reliability.

Durability and Resistance

PTFE is chemically inert and functions across a wide temperature range. This makes it ideal for bearings that are exposed to harsh weather, de-icing salts, and other environmental factors over decades of service without degradation.

Understanding the Key Design Parameters

A standard PTFE bearing only supports vertical loads and allows free horizontal movement. Any other force must be explicitly accounted for in the design of the complete bearing assembly.

The Challenge of Uplift Forces

Forces like heavy winds or certain mechanical system characteristics can create uplift, or a tensile load, that threatens to pull the bearing apart. A simple sliding bearing has no inherent resistance to this force.

Solutions for Uplift and Restraint

To counteract uplift, the assembly must include mechanical restraints. These are often T-shaped dowel pins or brackets that hold the upper and lower plates together while still allowing for the required sliding movement. These components must be engineered to handle the maximum expected tensile load.

Accommodating Rotation

Standard flat PTFE bearings can only accommodate minuscule rotation (fractions of a degree). If greater rotation or misalignment is expected, the bearing must incorporate other elements. Elastomeric pads (like neoprene) can be added to absorb small rotations, while spherical bearings are required for applications with significant rotational demands.

How to Specify the Right PTFE Bearing

Designing a structural bearing begins with a clear definition of all expected loads and movements. The manufacturer uses these parameters to engineer an assembly that will perform safely for the life of the structure.

- If your primary focus is supporting high vertical loads with thermal expansion: Ensure the PTFE surface area is calculated with a conservative safety factor (often 50-60%) to handle the specified load without creep or failure.

- If your primary focus is accommodating multi-directional movement: Clearly define the required longitudinal and transverse travel so the steel plates can be dimensioned to allow for the full range of motion.

- If your structure is subject to significant wind, seismic, or rotational forces: The design must include specific mechanisms like uplift restraints (dowel pins) or elastomeric/spherical components to manage forces beyond simple compression and sliding.

A well-designed PTFE bearing is a simple yet powerful engineering solution that protects the long-term integrity of critical infrastructure.

Summary Table:

| Key Property | Role in Structural Bearings |

|---|---|

| Low Coefficient of Friction | Enables smooth horizontal sliding under vertical loads. |

| High Compressive Strength (up to 2,900 psi) | Supports immense structural weights with a small surface area. |

| Chemical Inertness & Durability | Ensures long-term performance in harsh environmental conditions. |

| Accommodates Multi-Directional Movement | Manages thermal expansion, contraction, and seismic shifts. |

Need high-performance PTFE components for your structural or industrial application? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your materials meet the highest standards of durability and performance. Contact us today to discuss your specific needs and leverage our custom fabrication capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the two main phases in PTFE production? From Raw Materials to High-Performance Polymer

- What are the advantages of PTFE slide bearings over conventional supports? Achieve Frictionless Movement for Durable Structures

- What are the main features of the PTFE seat butterfly valve? Unlock Superior Corrosion Resistance & Zero-Leakage Sealing

- What are PTFE seals commonly known as? Discover Teflon® Seals for Extreme Performance

- How does the heat resistance of Teflon sheets benefit industrial applications? Unlock Performance Under Thermal Stress

- How do the lightweight and durable properties of PTFE bushes benefit industrial use? Boost Efficiency & Cut Costs

- Why should negative pressure be avoided in PTFE lined butterfly valves? Prevent Catastrophic Liner Collapse

- What additional benefits do PTFE rotary shaft seals offer? Achieve Superior Reliability in Extreme Conditions