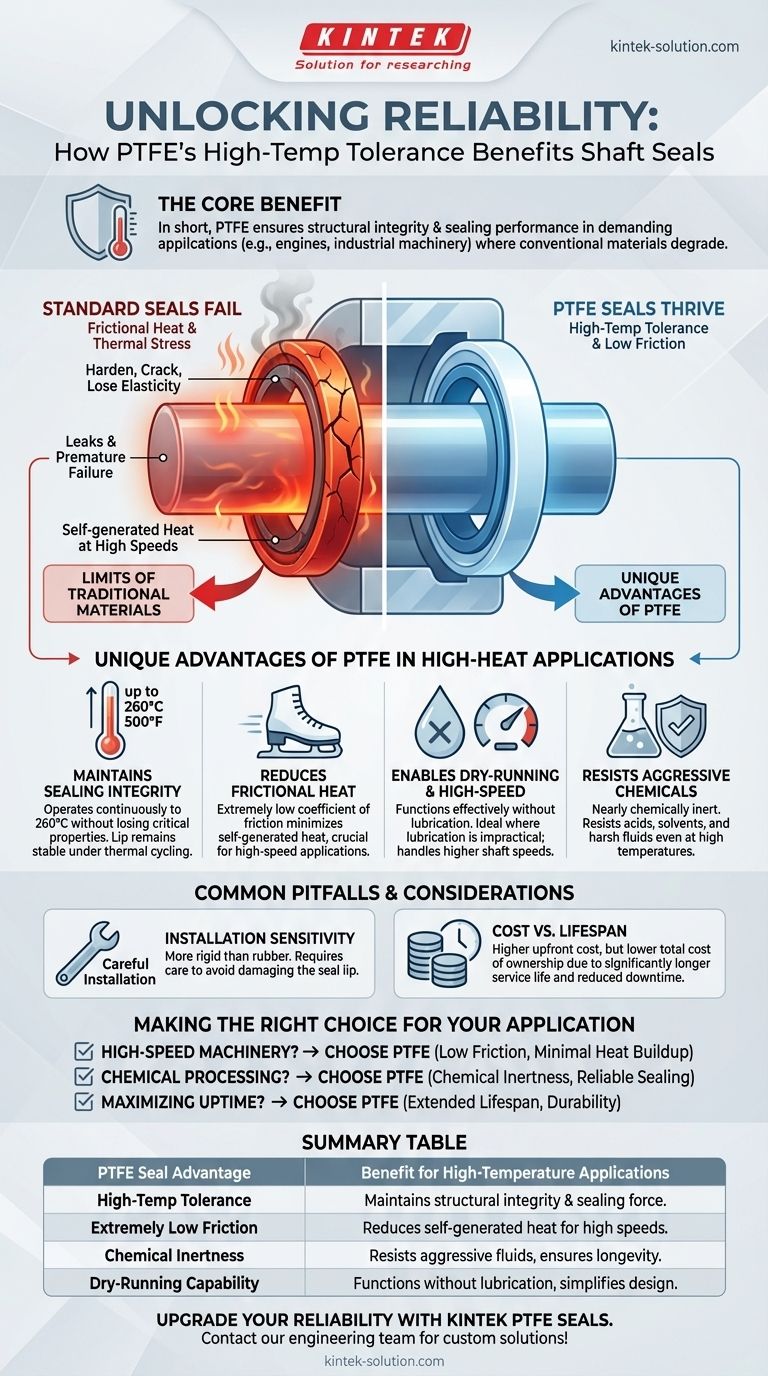

In short, PTFE's high-temperature tolerance ensures shaft seals maintain their structural integrity and sealing performance in demanding applications like engines and industrial machinery. Where conventional materials would degrade, soften, or fail under thermal stress, PTFE continues to provide a reliable barrier, preventing leaks and extending the life of the equipment.

The true advantage of PTFE isn't just its ability to withstand high temperatures, but how this resilience combines with its exceptionally low friction and chemical inertness to deliver unmatched sealing performance where other materials simply cannot survive.

Why Standard Seals Fail in Extreme Conditions

The Limits of Traditional Materials

Traditional shaft seals, often made from elastomeric materials like rubber, have a much narrower operating temperature range.

When exposed to high heat, these materials can harden, crack, or lose their elasticity. This degradation compromises their ability to maintain a consistent seal, leading to leaks and premature equipment failure.

The Problem of Frictional Heat

At high rotational speeds, the friction between a standard seal and the shaft generates significant heat. This self-generated heat can easily push a conventional seal beyond its thermal limits, even if the application's ambient temperature is within range.

The Unique Advantages of PTFE in High-Heat Applications

Maintaining Sealing Integrity Under Thermal Stress

PTFE's primary benefit is its ability to operate continuously at temperatures up to 260°C (500°F) without losing its critical physical properties.

This means the seal lip remains stable and continues to exert the correct force against the shaft, ensuring a reliable seal even under extreme thermal cycling.

Reducing Frictional Heat Generation

PTFE has an extremely low coefficient of friction, allowing it to glide smoothly over rotating shafts.

This inherent lubricity minimizes the generation of frictional heat, reducing the thermal load on the seal itself. This is a critical advantage in high-speed applications where friction is a primary cause of seal failure.

Enabling Dry-Running and High-Speed Capabilities

The combination of high-temperature tolerance and low friction allows PTFE seals to function effectively without lubrication.

This dry-running capability makes them ideal for applications where lubrication is impractical or undesirable, and it enables them to perform reliably at much higher shaft speeds than rubber seals.

Resisting Aggressive Chemicals at High Temperatures

Many industrial processes involve both high temperatures and corrosive chemicals. PTFE is nearly chemically inert, resisting degradation from acids, solvents, and other aggressive fluids.

This ensures the seal's longevity in harsh chemical environments where heat would otherwise accelerate the breakdown of less robust materials.

Common Pitfalls and Considerations

Installation Sensitivity

While highly durable in operation, PTFE seals can be more rigid than their rubber counterparts. This requires greater care during installation to avoid damaging the seal lip, which can lead to immediate leaks.

Cost vs. Lifespan

PTFE seals typically have a higher upfront cost compared to standard elastomeric seals. However, this initial investment is often justified by a significantly longer service life, reduced maintenance, and less equipment downtime, leading to a lower total cost of ownership.

Making the Right Choice for Your Application

Choosing the correct seal material is critical for operational reliability. The decision should be based on a clear understanding of your specific environmental and performance demands.

- If your primary focus is high-speed machinery: Choose PTFE for its low friction, which minimizes heat buildup and allows for superior performance.

- If your primary focus is chemical processing: PTFE's chemical inertness provides the most reliable sealing solution for aggressive fluids, especially at elevated temperatures.

- If your primary focus is maximizing uptime and reducing maintenance: The extended lifespan and durability of PTFE seals in extreme conditions make them the superior long-term investment.

Ultimately, PTFE seals provide a definitive engineering solution for the most demanding sealing challenges where performance and reliability cannot be compromised.

Summary Table:

| PTFE Seal Advantage | Benefit for High-Temperature Applications |

|---|---|

| High-Temp Tolerance (up to 260°C/500°F) | Maintains structural integrity and sealing force where other materials fail. |

| Extremely Low Friction | Reduces self-generated frictional heat, ideal for high-speed machinery. |

| Chemical Inertness | Resists aggressive fluids, ensuring longevity in harsh chemical environments. |

| Dry-Running Capability | Functions effectively without lubrication, simplifying design and maintenance. |

Upgrade your equipment's reliability with high-performance PTFE shaft seals from KINTEK.

When standard seals fail under thermal stress, our precision-manufactured PTFE components—including seals, liners, and labware—deliver unmatched durability and chemical resistance for the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your most demanding applications.

Reduce downtime and extend service life. Contact our engineering team today for a solution tailored to your high-temperature and high-speed challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech