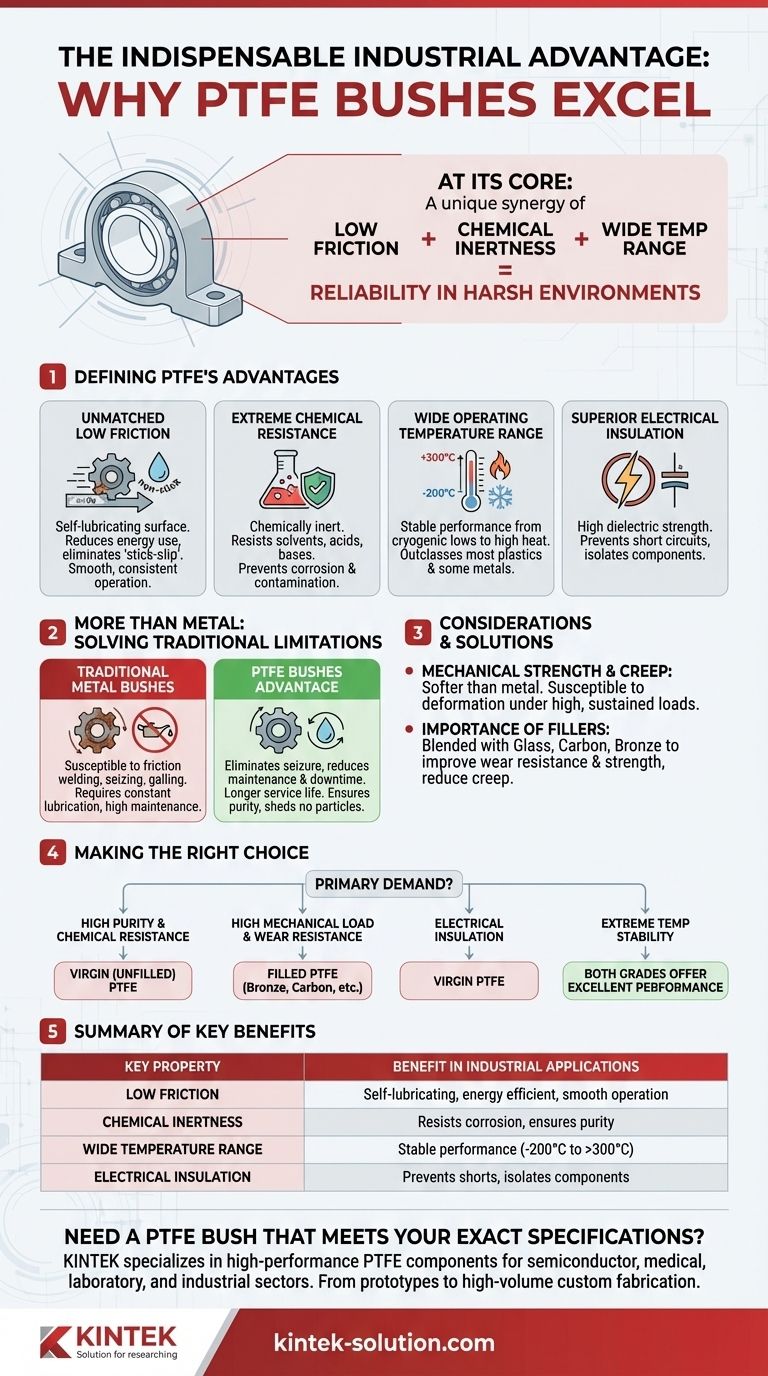

At its core, a PTFE bush is considered indispensable because it offers a unique combination of extremely low friction, complete chemical inertness, and a wide operating temperature range. This allows it to function reliably in harsh industrial environments where traditional metal or other plastic components would quickly fail due to wear, corrosion, or heat degradation.

The fundamental challenge in modern industry is maintaining operational reliability under increasingly extreme conditions. PTFE bushes solve this by providing a "self-lubricating," chemically-impervious, and thermally-stable interface that minimizes wear, prevents contamination, and drastically reduces maintenance downtime.

The Core Properties Defining PTFE's Advantage

To understand why PTFE (Polytetrafluoroethylene) is so effective, we must look at its distinct material properties. It isn't just one feature, but the synergy of several, that makes it a superior choice for bushes and bearings.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This creates an incredibly slick, non-stick surface.

For a bush, this means it is essentially self-lubricating. It reduces the energy required for movement and virtually eliminates the "stick-slip" behavior common in other materials, ensuring smooth and consistent operation in components like bearings, gears, and slide plates.

Extreme Chemical Resistance

PTFE is almost completely chemically inert. It is resistant to nearly all industrial chemicals, solvents, acids, and bases.

This property is critical in applications like chemical processing or pharmaceutical manufacturing, where the bush will be exposed to corrosive substances. It guarantees the component will not degrade, rust, or contaminate the process medium.

Wide Operating Temperature Range

PTFE maintains its key properties across a vast range of temperatures, from cryogenic lows to a high melting point well over 300°C (572°F).

This thermal stability ensures predictable performance whether the application is in a super-cooled environment or a high-heat industrial process, outclassing most other plastics and even some metals.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength and high electrical resistance.

In electromechanical systems, a PTFE bush can serve a dual purpose: providing low-friction mechanical support while also electrically isolating components from each other, preventing short circuits in motors, transformers, and switches.

Why This Matters More Than Metal Alternatives

While metal bushes are strong, their limitations become clear in demanding environments where PTFE excels. The choice to use PTFE is often a strategic decision to overcome the inherent weaknesses of traditional materials.

Eliminating Seizure and Galling

Metal-on-metal contact, especially without constant lubrication, can lead to friction welding, seizing, or galling, causing catastrophic component failure.

PTFE's self-lubricating nature prevents this entirely. It ensures parts continue to move freely even under pressure, significantly improving long-term reliability.

Reducing Maintenance and Downtime

The durability, chemical resistance, and self-lubricating properties of PTFE bushes mean they have a longer service life with minimal need for maintenance.

This directly translates to reduced operational downtime and lower lifetime costs, a crucial factor in any industrial setting. Components like PTFE gaskets and seals provide this same benefit, ensuring leak-proof reliability.

Ensuring Purity and Preventing Contamination

In industries like food and beverage, pharmaceuticals, or semiconductor manufacturing, preventing contamination is paramount.

Because PTFE is inert and sheds no particles, it ensures the purity of the product. Metal bushes, conversely, can corrode or shed material, introducing contaminants into the system.

Understanding the Trade-offs and Considerations

No material is perfect for every situation. Being a trusted advisor means acknowledging the limitations and a few critical realities of working with PTFE.

Mechanical Strength and Creep

Compared to metals, PTFE is a softer material. Under very high, sustained loads, it can be susceptible to creep, which is a slow deformation over time.

This is a critical design consideration where mechanical strength is the primary requirement.

The Importance of Fillers

To overcome its relative softness, PTFE is often blended with fillers like glass, carbon, bronze, or graphite.

These additives can dramatically improve wear resistance, increase strength, and reduce creep. However, they can also alter other properties, such as chemical resistance or electrical insulation, requiring a careful balance for the specific application.

The Critical Role of Manufacturing

The performance of a PTFE bush is highly dependent on its grade and the manufacturing process (e.g., molded vs. extruded).

Testing is crucial to verify that the specific material chosen meets the electrical and mechanical requirements of the end product. Assuming all PTFE is the same can lead to application failure.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on the primary demands of your project.

- If your primary focus is high purity and chemical resistance: Use a virgin (unfilled) grade of PTFE to ensure maximum inertness.

- If your primary focus is high mechanical load and wear resistance: Choose a filled PTFE, such as a bronze- or carbon-filled variant, to improve strength and durability.

- If your primary focus is electrical insulation: A virgin PTFE is often the best choice for its superior dielectric properties.

- If your primary focus is extreme temperature stability: Both virgin and filled PTFE grades offer excellent performance, but the choice of filler can impact thermal conductivity.

Ultimately, the indispensability of PTFE bushes comes from their ability to solve multiple engineering challenges at once, enabling innovation and reliability where other materials simply cannot perform.

Summary Table:

| Key Property | Benefit in Industrial Applications |

|---|---|

| Low Friction | Self-lubricating, reduces energy use, eliminates stick-slip |

| Chemical Inertness | Resists corrosion, ensures purity in sensitive processes |

| Wide Temperature Range | Stable performance from cryogenic to over 300°C |

| Electrical Insulation | Prevents short circuits, isolates components |

Need a PTFE bush that meets your exact specifications? KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require virgin PTFE for purity or filled grades for enhanced strength, we provide custom fabrication from prototypes to high-volume orders. Contact our experts today to discuss how our precision PTFE solutions can extend equipment life, reduce downtime, and ensure reliability in your most demanding applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments