The fundamental reason PTFE bearings and components are preferred in chemical processing is their near-total chemical inertness. This property ensures they will not degrade, corrode, or react when exposed to the vast majority of aggressive acids, bases, and solvents, leading to unparalleled operational reliability and safety in harsh environments.

The decision to use PTFE in chemical equipment is not merely about material selection. It is a strategic choice to mitigate risk, ensuring equipment longevity, process purity, and personnel safety in environments where component failure is not an option.

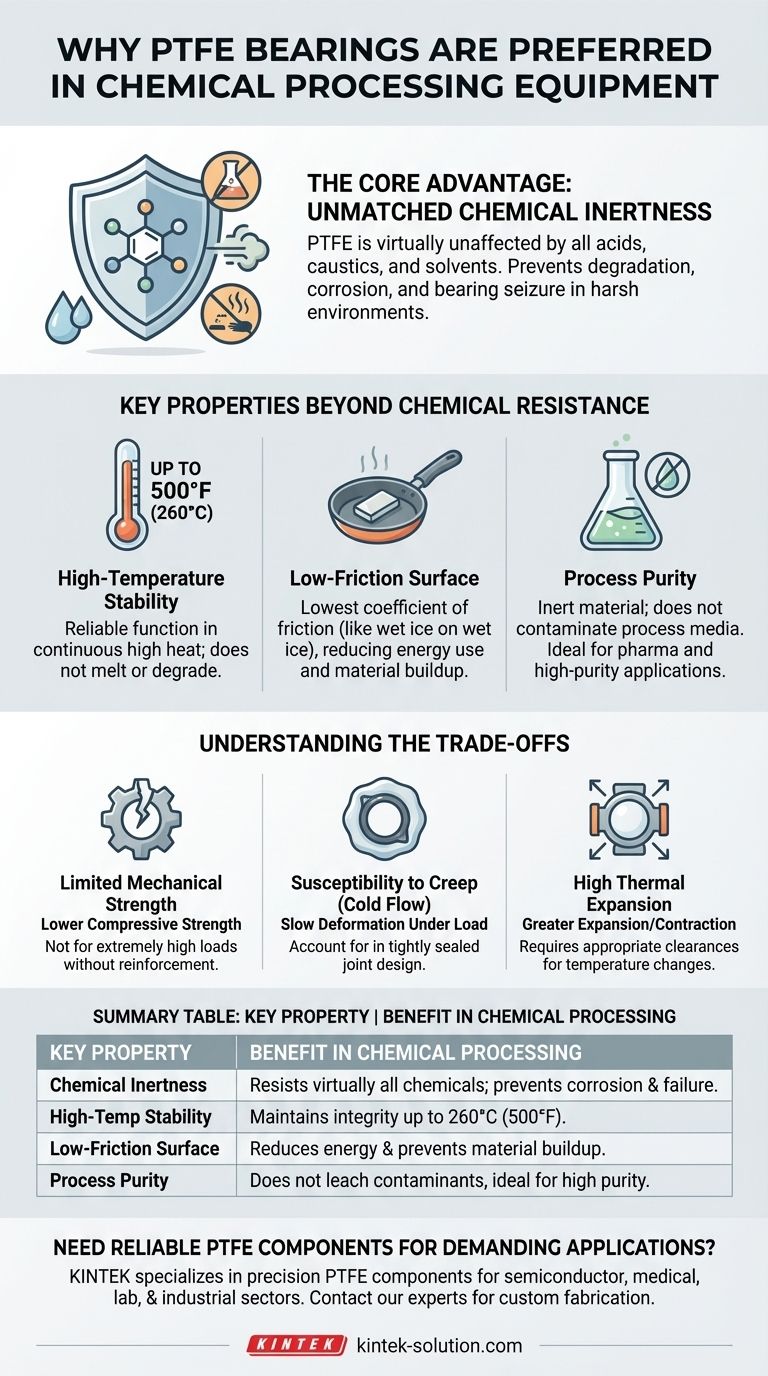

The Core Advantage: Unmatched Chemical Inertness

The primary value of Polytetrafluoroethylene (PTFE) comes from its unique molecular structure, which renders it exceptionally resistant to chemical attack. This is the bedrock of its utility in the chemical processing industry.

What "Chemically Inert" Means

PTFE is virtually unaffected by all acids, caustics, and solvents. This means it will not swell, soften, or break down when in direct contact with these substances.

This property ensures that components like bearings, seals, gaskets, and linings maintain their structural integrity and performance over long periods, directly preventing equipment failure.

Preventing Corrosive Failure

Metals and many other polymers will corrode or degrade rapidly in the same environments where PTFE thrives. This corrosion leads to bearing seizure, leaks, and catastrophic equipment failure.

By using PTFE, engineers design a system that is fundamentally resistant to its most common failure mode: chemical attack. This extends the service life of critical equipment like pumps, valves, and mixing vessels.

Ensuring Process Purity

Because PTFE is inert, it does not leach chemicals or contaminants into the process medium. This is critical in applications like pharmaceuticals, food processing, and high-purity chemical manufacturing.

The material ensures that the final product remains uncontaminated by the equipment used to process it.

Key Properties Beyond Chemical Resistance

While its chemical stability is the main driver, other properties of PTFE make it uniquely suited for these demanding applications.

High-Temperature Stability

PTFE functions reliably in continuous service temperatures up to 500°F (260°C). Many chemical reactions and processes occur at elevated temperatures, and PTFE maintains its integrity without melting or degrading.

Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" property is highly beneficial for bearings, reducing operational energy requirements and preventing material buildup on surfaces.

Versatility in Application

The references highlight that PTFE's value extends beyond just bearings. It is the material of choice for gaskets, vessel linings, pump interiors, seals, spacers, and dip tubes.

This versatility allows engineers to use a single, trusted material for nearly all "wetted" components—those that directly contact the process chemical—simplifying design and inventory.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of PTFE is critical for proper application and design. Its strengths in chemical environments are balanced by trade-offs in its mechanical properties.

Limited Mechanical Strength

Compared to metal bearings, standard PTFE has a lower compressive strength and load-bearing capacity. It is not suitable for extremely high-load applications without reinforcement (e.g., glass or carbon fillers).

Susceptibility to Creep (Cold Flow)

Under a constant, sustained load, PTFE can slowly deform over time. This phenomenon, known as creep or cold flow, must be accounted for in the design of tightly sealed joints or load-bearing components.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than metals do. Engineers must design components with appropriate clearances to accommodate this thermal expansion and prevent parts from seizing or failing.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to the primary demands of the application.

- If your primary focus is reliability in highly corrosive media: PTFE is the default choice for any component that will be in direct contact with aggressive chemicals.

- If your primary focus is handling high mechanical loads: You must consider either a filled grade of PTFE or an entirely different material class, like a high-performance metal or ceramic.

- If your primary focus is preventing product contamination: PTFE's inertness makes it an ideal choice to ensure the purity of the chemical medium.

Ultimately, PTFE's dominance in chemical processing is a direct result of its ability to solve the industry's most critical challenge: maintaining equipment integrity in chemically hostile environments.

Summary Table:

| Key Property | Benefit in Chemical Processing |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents corrosion and failure. |

| High-Temperature Stability | Maintains integrity at continuous service temperatures up to 260°C (500°F). |

| Low-Friction Surface | Reduces energy requirements and prevents material buildup. |

| Process Purity | Does not leach contaminants, ideal for pharmaceuticals and high-purity manufacturing. |

Need reliable PTFE components for your demanding chemical applications?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom bearings—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your equipment operates safely and reliably in the most aggressive chemical environments.

Contact our experts today to discuss custom fabrication from prototypes to high-volume orders and enhance your process reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support