In short, glass-filled PTFE rods are used in medical devices because they combine the exceptional biocompatibility and chemical inertness of standard PTFE with the significantly enhanced mechanical strength, stiffness, and wear resistance imparted by the glass fibers. This composite material creates components that are safe for contact with the human body and durable enough to withstand the mechanical stresses of surgical use or long-term implantation.

The core reason for choosing glass-filled PTFE over standard PTFE is to gain critical improvements in mechanical performance—like strength and creep resistance—without sacrificing the properties that make PTFE medically safe in the first place.

The Foundation: PTFE's Inherent Biocompatibility

Before understanding the role of the glass filler, it's essential to recognize why Polytetrafluoroethylene (PTFE) is a foundational polymer in the medical field. Its unique properties make it an ideal starting point for biocompatible components.

Unmatched Biological Inertness

PTFE is extremely non-reactive. It does not react with bodily fluids or tissue, minimizing the risk of adverse reactions, inflammation, or rejection when used in implants or surgical instruments.

Exceptional Chemical Resistance

The material is resistant to virtually all common chemicals and aggressive sterilization agents used in medical settings. This ensures the component's integrity and purity are maintained throughout its lifecycle.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" quality is crucial for reducing wear on moving parts and minimizing irritation to surrounding body tissues.

The Upgrade: How Glass Fillers Enhance Performance

While pure PTFE is biocompatible, it is also mechanically soft. Adding glass fibers directly addresses these limitations, creating a material suited for more demanding structural roles.

A Significant Boost in Strength and Stiffness

The primary benefit of adding glass is a dramatic increase in compressive strength and stiffness. This prevents the material from deforming under load, a critical feature for structural components in instruments or implants.

Superior Wear and Creep Resistance

Glass-filled PTFE exhibits vastly improved wear resistance. It also resists "creep," which is the tendency of a material to slowly deform over time when under a constant load. This ensures long-term dimensional stability for critical parts like seals or bearings.

Increased Durability and Tear Resistance

The glass fibers act as a reinforcement matrix within the PTFE, significantly increasing its tear resistance and overall durability. This makes it suitable for reusable instruments or components that experience repeated mechanical stress.

Common Pitfalls and Trade-offs

Selecting glass-filled PTFE is an engineering decision that involves clear trade-offs. It is not a universal solution for every medical application.

Reduced Flexibility

The same properties that increase stiffness also make the material much less flexible than unfilled PTFE. If an application requires high flexibility or a component needs to bend, pure PTFE is the superior choice.

Potential Abrasiveness

The glass fibers, while enhancing wear resistance of the part itself, can be abrasive to softer mating surfaces. If a glass-filled PTFE component will rub against a softer plastic or metal, it could cause premature wear on the other part.

Thermal Expansion

Like all polymers, PTFE has a coefficient of thermal expansion that must be considered in the design phase, especially for devices that will undergo temperature cycling during sterilization or use.

Making the Right Choice for Your Device

Your material selection should be driven by the specific mechanical and biological demands of the application.

- If your primary focus is biocompatibility in a low-stress environment: Standard, unfilled PTFE is often sufficient and more cost-effective for applications like liners or flexible tubing.

- If your primary focus is structural integrity and long-term wear resistance: Glass-filled PTFE is the definitive choice for load-bearing components like bushings, seals, or durable instrument parts.

- If your primary focus is creating a seal against a sensitive surface: You must evaluate the potential for abrasion and consider if an alternative filler or a different grade of material is more appropriate.

By understanding this balance between inherent safety and enhanced performance, you can select the material that delivers both reliability and the required mechanical properties for your device.

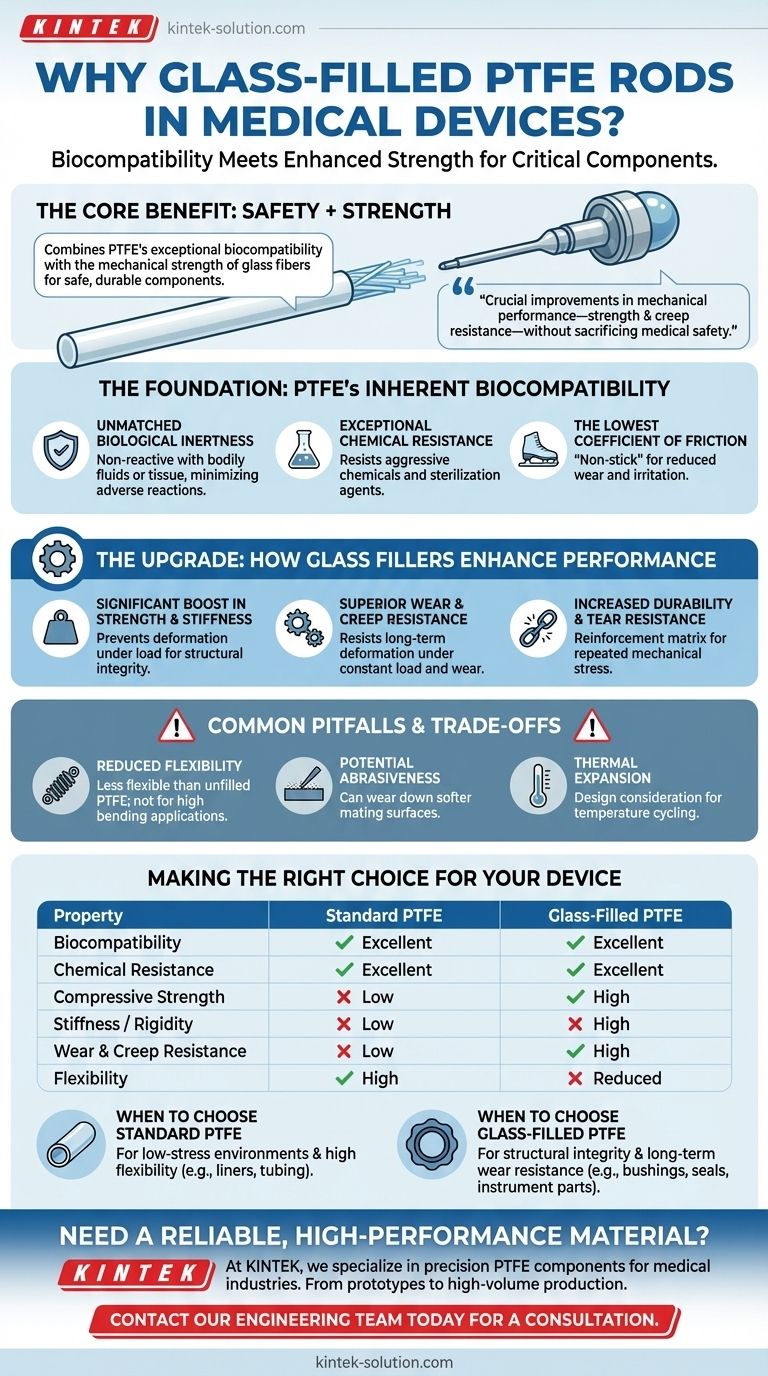

Summary Table:

| Property | Standard PTFE | Glass-Filled PTFE |

|---|---|---|

| Biocompatibility | Excellent | Excellent |

| Chemical Resistance | Excellent | Excellent |

| Compressive Strength | Low | High |

| Stiffness / Rigidity | Low | High |

| Wear & Creep Resistance | Low | High |

| Flexibility | High | Reduced |

Need a reliable, high-performance material for your medical device?

At KINTEK, we specialize in manufacturing precision PTFE components, including glass-filled grades, for the medical, semiconductor, and laboratory industries. Our custom fabrication services—from prototypes to high-volume production—ensure you get the exact material properties and dimensional accuracy your application demands.

Let's discuss how our expertise can enhance your device's safety and performance.

Contact our engineering team today for a consultation

Visual Guide

Related Products

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What makes extruded PTFE rods chemically resistant? Unmatched Stability from its Molecular Structure

- Why are PTFE rods suitable for medical applications? Unmatched Safety and Sterilization Performance

- What are the most popular and processed forms of PTFE materials? A Guide to Rods, Tubes, Sheets & Tapes

- How are PTFE-lined pipes manufactured? A Guide to Durable, Corrosion-Resistant Piping

- What advantages do extruded PTFE rods offer? Superior Durability for High-Stress Applications