When selecting a high-performance polymer, the manufacturing method is as crucial as the material itself. Extruded PTFE rods offer significant advantages over other forms, primarily due to a specialized extrusion and sintering process. This method creates a denser, more uniform molecular structure, resulting in enhanced durability and chemical resistance while preserving the exceptionally low friction inherent to all PTFE.

The core advantage of extruded PTFE is not a change in the material's fundamental properties, but rather an optimization of its physical structure. This makes it the superior choice for applications demanding maximum durability and resistance to mechanical stress and chemical attack.

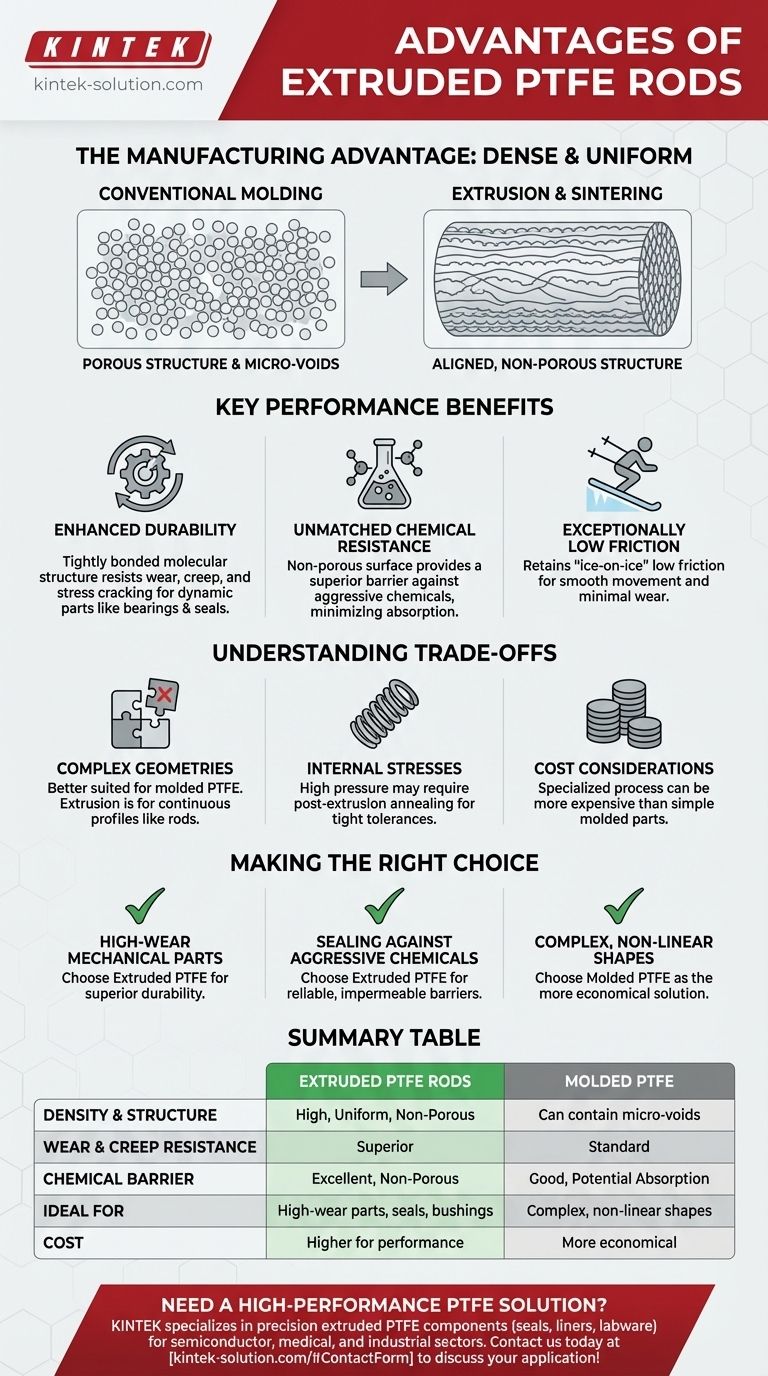

The Manufacturing Process Defines Performance

The unique benefits of extruded PTFE are a direct result of how it is formed. Understanding this process is key to understanding its superior characteristics in demanding environments.

How Extrusion Aligns the Structure

The process begins by forcing granular PTFE resin through a die under immense pressure. This action helps to align the long polymer chains, creating a more organized internal structure compared to molding, where particles are simply compressed together.

The Critical Role of Sintering

After extrusion, the rod undergoes a controlled heating and cooling cycle known as sintering. This fuses the PTFE particles together, eliminating micro-voids and creating a solid, non-porous material with very high integrity.

The Result: Superior Density and Uniformity

This combination of extrusion and sintering produces a rod that is remarkably dense and uniform throughout its length. This structural consistency is the foundation for its enhanced performance characteristics.

Key Performance Advantages Explained

The dense, non-porous structure created during extrusion translates directly into tangible benefits for mechanical and chemical applications.

Enhanced Durability and Wear Resistance

The tightly bonded molecular structure makes extruded PTFE highly resistant to wear, creep, and stress cracking. This makes it ideal for dynamic components like bearings, bushings, and seals that are subjected to continuous mechanical stress.

Unmatched Chemical Resistance

While all PTFE is famously inert, the non-porous surface of an extruded rod provides a superior barrier. It minimizes the potential for absorption by aggressive chemicals, ensuring maximum stability and longevity in harsh chemical environments.

Exceptionally Low Coefficient of Friction

Extruded PTFE retains the material's hallmark low friction, which is often compared to the friction of ice on ice. This property is critical for applications requiring smooth, low-energy movement and minimal material wear over time.

Understanding the Trade-offs

No material or process is perfect for every situation. Objectivity requires acknowledging the specific contexts where extruded PTFE may not be the optimal choice.

Not Suited for Complex Geometries

The extrusion process is designed to create continuous, uniform profiles like rods and tubes. For intricate, complex shapes, molded PTFE is a more practical and cost-effective manufacturing method.

Potential for Internal Stresses

The high pressures involved in extrusion can sometimes create internal stresses within the material. For applications requiring extremely tight machining tolerances, a post-extrusion annealing (stress-relieving) step may be necessary.

Cost Considerations for Simpler Parts

Due to the specialized multi-step process, extruded PTFE can be more expensive than simple molded PTFE parts. The performance benefits must justify the potential increase in material cost.

Making the Right Choice for Your Application

Your final decision should be guided by the specific performance demands of your project.

- If your primary focus is high-wear mechanical parts: Choose extruded PTFE for its superior durability and low-friction surface, which ensures a longer service life.

- If your primary focus is sealing against aggressive chemicals: The dense, non-porous structure of extruded PTFE provides the most reliable and impermeable barrier.

- If your primary focus is creating a complex, non-linear shape: A molded PTFE component will be the more efficient and economical solution.

Ultimately, selecting the correct form of PTFE is about aligning the manufacturing process with the specific challenges of your application.

Summary Table:

| Feature | Extruded PTFE Rods | Molded PTFE |

|---|---|---|

| Density & Structure | High, uniform, non-porous | Can contain micro-voids |

| Wear & Creep Resistance | Superior | Standard |

| Chemical Barrier | Excellent, non-porous surface | Good, but potential for absorption |

| Ideal For | High-wear mechanical parts, seals, bushings | Complex, non-linear shapes |

| Cost Consideration | Higher for performance benefits | More economical for complex geometries |

Need a high-performance PTFE solution for demanding environments?

At KINTEK, we specialize in manufacturing precision extruded PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get the optimal material performance, whether you need prototypes or high-volume orders.

Contact us today to discuss how our extruded PTFE rods can enhance the durability and chemical resistance of your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech