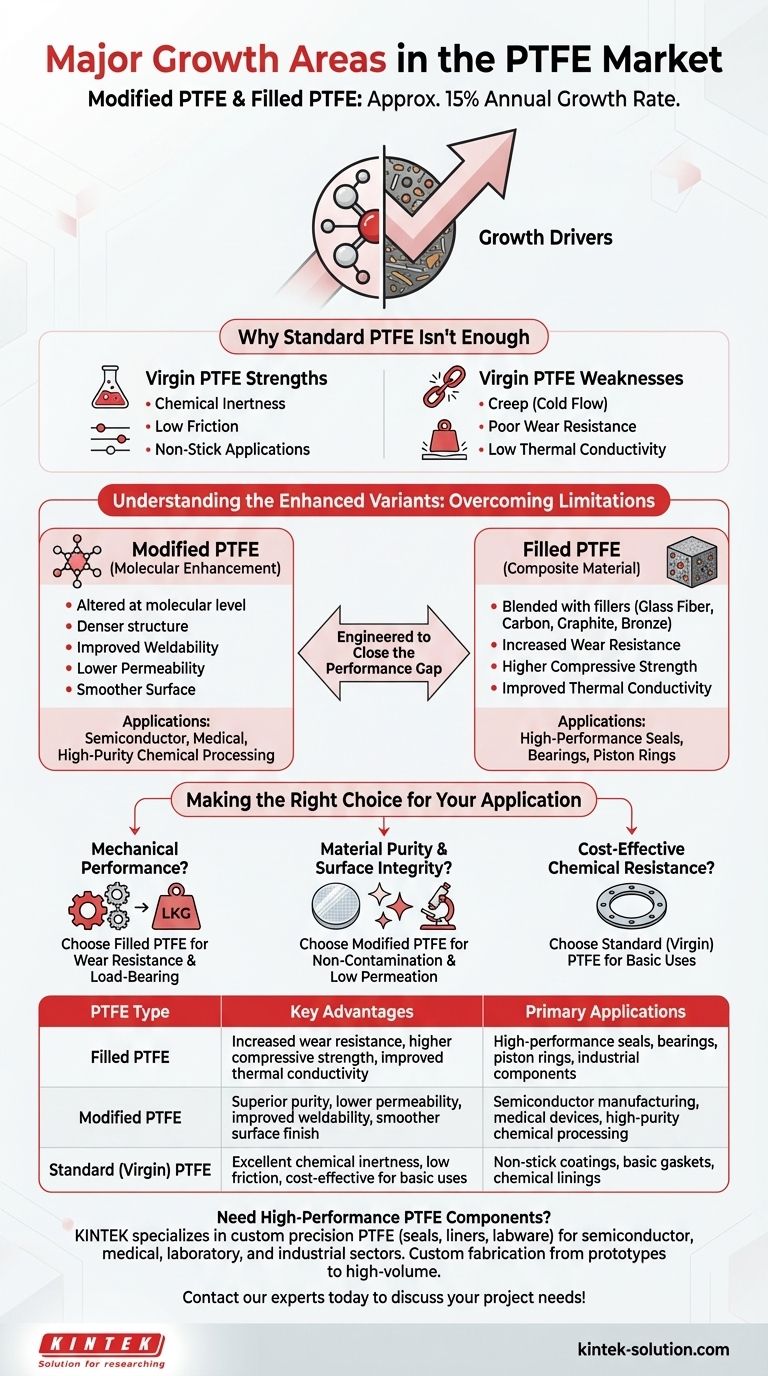

To be direct, the major growth areas in the PTFE market are Modified PTFE and Filled PTFE. These specialized sectors are expanding at a significant annual rate of approximately 15%, driven by the demand for materials that overcome the inherent limitations of standard PTFE in advanced applications.

The core reason for this growth is simple: while standard PTFE offers exceptional chemical resistance and low friction, its weaknesses in mechanical strength and wear resistance create a performance gap. Modified and Filled PTFE variants are engineered specifically to close this gap for more demanding industrial uses.

Why Standard PTFE Isn't Always Enough

To understand the growth of enhanced variants, we must first acknowledge the baseline properties of pure, or "virgin," Polytetrafluoroethylene (PTFE).

The Unmatched Strengths of Virgin PTFE

Virgin PTFE is a remarkable material known for two primary characteristics: an almost universal chemical inertness and one of the lowest coefficients of friction of any solid. This makes it an ideal choice for applications like non-stick coatings and basic chemical seals.

The Critical Mechanical Weaknesses

However, standard PTFE suffers from significant drawbacks under physical stress. It is susceptible to creep, or cold flow, where the material deforms permanently under a sustained load. It also has poor wear resistance and is a poor thermal conductor, limiting its use in high-load, high-speed applications.

Understanding the Growth Drivers: Enhanced PTFE

Modified and Filled PTFE were developed to retain the core benefits of the material while systematically addressing its mechanical and physical weaknesses. These enhancements unlock a much broader range of engineering applications.

What is Filled PTFE?

Filled PTFE is a composite material created by blending virgin PTFE resin with filler materials before it is sintered. Common fillers include glass fiber, carbon, graphite, and bronze.

Each filler imparts specific properties. For example, glass fibers dramatically increase compressive strength and wear resistance, while carbon improves thermal conductivity and hardness. This targeted enhancement makes Filled PTFE ideal for high-performance seals, bearings, and piston rings.

What is Modified PTFE?

Modified PTFE, sometimes called a second-generation PTFE, is altered at the molecular level. During polymerization, a tiny amount of a co-monomer is introduced, which creates a denser, less porous polymer structure.

This modification results in a material with a smoother surface finish, improved weldability, and significantly lower permeability to gases and chemicals. These properties are critical in the semiconductor and high-purity chemical processing industries where contamination and leaks are unacceptable.

Understanding the Trade-offs

While these enhanced materials solve key problems, their specialization comes with necessary trade-offs that must be considered during material selection.

The Impact on Core Properties

Adding fillers can slightly alter some of PTFE’s primary advantages. For instance, certain fillers may marginally decrease the material's overall chemical resistance or increase its coefficient of friction compared to the virgin grade.

The Cost Factor

The processes for creating both Filled and Modified PTFE are more complex and costly than producing standard resin. The filler materials themselves add to the expense, making these advanced grades a premium option reserved for applications where their enhanced performance is a necessity.

Making the Right Choice for Your Application

Selecting the correct type of PTFE depends entirely on the primary demands of your project. The key is to match the material's strengths to your most critical performance requirement.

- If your primary focus is mechanical performance: Filled PTFE is the solution for applications requiring high wear resistance, load-bearing capability, and reduced deformation under pressure.

- If your primary focus is material purity and surface integrity: Modified PTFE is engineered for industries like semiconductors where non-contamination, weldability, and low permeation are critical.

- If your primary focus is cost-effective chemical resistance: Standard (virgin) PTFE remains the undisputed choice for less mechanically demanding roles like basic gaskets or linings.

Ultimately, understanding these advanced PTFE variants allows engineers and designers to move beyond the limits of traditional materials and solve more complex challenges.

Summary Table:

| PTFE Type | Key Advantages | Primary Applications |

|---|---|---|

| Filled PTFE | Increased wear resistance, higher compressive strength, improved thermal conductivity | High-performance seals, bearings, piston rings, industrial components |

| Modified PTFE | Superior purity, lower permeability, improved weldability, smoother surface finish | Semiconductor manufacturing, medical devices, high-purity chemical processing |

| Standard (Virgin) PTFE | Excellent chemical inertness, low friction, cost-effective for basic uses | Non-stick coatings, basic gaskets, chemical linings |

Need High-Performance PTFE Components for Your Industry?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom seals, liners, and labware—specifically engineered for the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors. Whether you require the enhanced mechanical properties of Filled PTFE or the ultra-pure characteristics of Modified PTFE, we provide custom fabrication from prototypes to high-volume orders.

Let us help you solve complex material challenges with precision-engineered PTFE solutions. Contact our experts today to discuss your project needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications