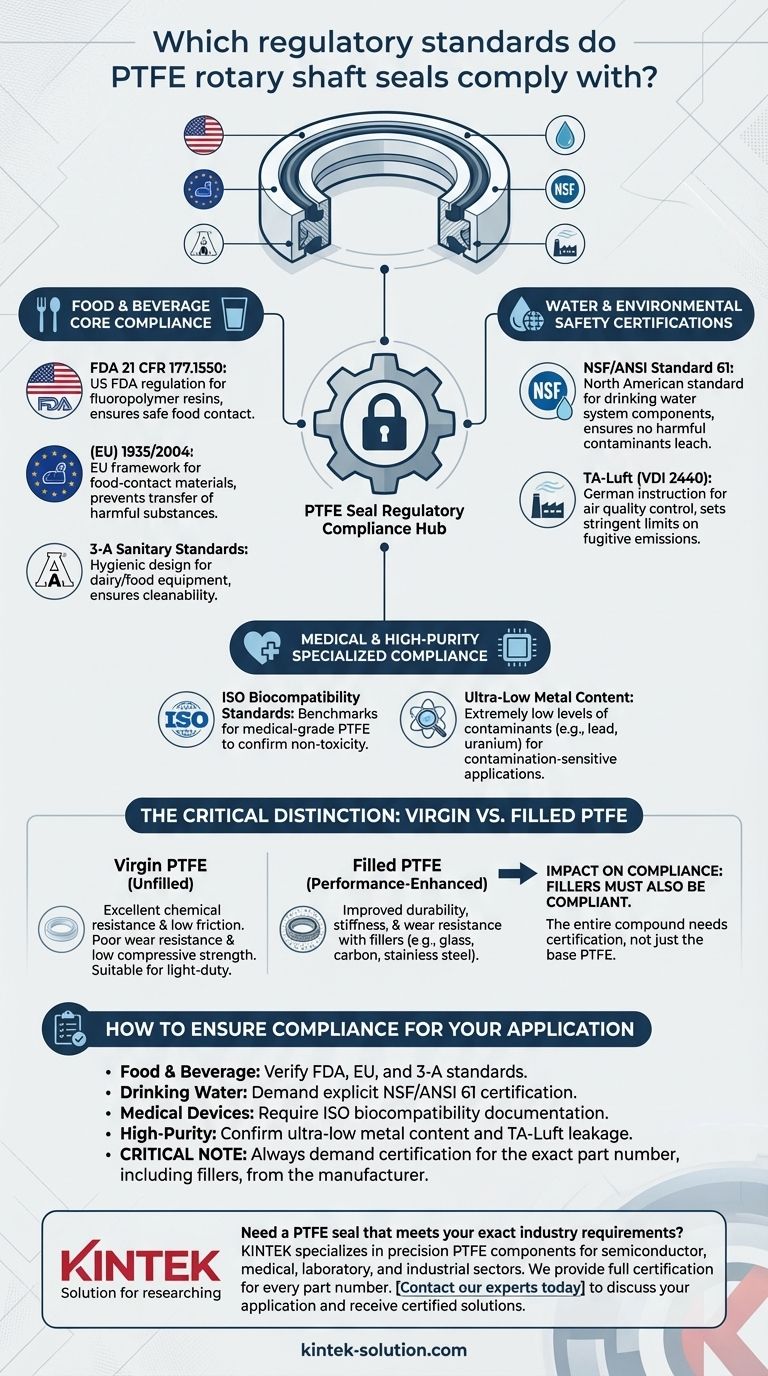

When selecting PTFE rotary shaft seals for regulated industries, they must adhere to a specific set of rigorous standards to ensure safety, purity, and performance. PTFE seals can comply with key regulations for food contact, drinking water systems, and medical applications, including FDA 21 CFR 177.1550, (EU) 1935/2004, 3-A Sanitary Standards, and NSF/ANSI Standard 61.

The core issue is not whether the base PTFE material is compliant, but whether the specific, final seal product—including any performance-enhancing fillers—meets the precise standard required for your application. Always demand certification for the exact part number you intend to use.

Core Compliance for Food and Beverage

In food and beverage processing, material safety is non-negotiable. Seals must prevent contamination and be made from substances that are safe for direct or indirect food contact.

FDA 21 CFR 177.1550

This is the foundational U.S. Food and Drug Administration regulation for fluoropolymer resins. Compliance ensures the PTFE material is safe for repeated use in contact with food.

(EU) 1935/2004

This is the primary European Union framework for all food-contact materials. It mandates that materials must not transfer their constituents to food in quantities that could endanger human health or change the food's composition.

3-A Sanitary Standards (18-03 & 20-27)

These standards go beyond material composition to address the hygienic design of equipment used in dairy and food processing. Seals compliant with 3-A standards are designed to be easily cleanable and prevent microbial growth.

Certifications for Water and Environmental Safety

When used in public water systems or applications where leakage is a critical concern, PTFE seals must meet standards that protect both public health and the environment.

NSF/ANSI Standard 61

This is the key North American standard for materials and equipment that come into contact with drinking water. Certification to NSF/ANSI 61 ensures that the seal will not leach harmful contaminants into the water supply.

TA-Luft (VDI 2440/2200)

This German technical instruction on air quality control sets stringent limits on fugitive emissions. Seals meeting this leakage requirement are critical for applications handling volatile or hazardous fluids, ensuring process and environmental safety.

Specialized Compliance for Medical and High-Purity Uses

In medical, pharmaceutical, and semiconductor applications, the requirements for material purity and biocompatibility are the most stringent.

ISO Standards and Biocompatibility

Medical-grade PTFE must comply with specific International Organization for Standardization (ISO) benchmarks. These standards govern biocompatibility, confirming the material is non-toxic and will not cause adverse reactions when used in medical devices.

Ultra-Low Metal Content

For contamination-sensitive applications like semiconductor manufacturing, the material's purity is paramount. High-purity PTFE seals are manufactured to maintain extremely low levels of metal contaminants, such as lead and uranium, to prevent process contamination.

The Critical Distinction: Virgin vs. Filled PTFE

Understanding the type of PTFE used in your seal is essential, as it directly impacts both performance and compliance.

The Limitations of Virgin PTFE

Pure, unfilled PTFE has excellent chemical resistance and low friction but suffers from poor wear resistance and low compressive strength. It is generally suitable only for light-duty, slow-speed applications.

The Role of Performance-Enhancing Fillers

To overcome these limitations, fillers like glass, carbon, or stainless steel are added to the PTFE matrix. These fillers dramatically improve the seal's durability, stiffness, and wear resistance, making it suitable for demanding conditions.

The Impact on Compliance

This is the most critical point: the fillers themselves must also be compliant with the target regulation. A seal made with FDA-compliant PTFE but a non-compliant filler is not considered food-safe. The entire compound must be certified.

How to Ensure Compliance for Your Application

Always verify the certification for the final product, not just the base material. The manufacturer's documentation is your only source of truth.

- If your primary focus is food and beverage processing: Verify compliance with FDA 21 CFR 177.1550, (EU) 1935/2004, and relevant 3-A Sanitary Standards.

- If your primary focus is drinking water systems: Demand explicit certification to NSF/ANSI Standard 61.

- If your primary focus is medical devices: Require documentation showing compliance with the necessary ISO standards for biocompatibility.

- If your primary focus is high-purity or environmental control: Confirm ultra-low metal content analysis and that TA-Luft leakage requirements are met.

Ultimately, your responsibility is to request and confirm the specific compliance documentation from the seal manufacturer for the exact product you are sourcing.

Summary Table:

| Industry | Key Standards | Primary Focus |

|---|---|---|

| Food & Beverage | FDA 21 CFR 177.1550, (EU) 1935/2004, 3-A Sanitary Standards | Material safety & hygienic design |

| Water Systems | NSF/ANSI Standard 61 | Prevention of water contamination |

| Medical/Pharmaceutical | ISO Biocompatibility Standards | Biocompatibility & non-toxicity |

| High-Purity/Environmental | TA-Luft (VDI 2440), Ultra-Low Metal Content | Emission control & contamination prevention |

Need a PTFE seal that meets your industry's exact regulatory requirements?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand that compliance isn't just about the base material; it's about the entire product, including performance-enhancing fillers. That's why we provide full certification for every part number, from prototypes to high-volume orders.

Let us ensure your seals are fully compliant and performance-optimized. Contact our experts today to discuss your application and receive certified solutions tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications