For high-temperature applications, PEEK (Polyetheretherketone) is the superior choice among common thermoplastic ball valve seat materials. Its molecular structure provides exceptional thermal stability, allowing it to maintain mechanical integrity and sealing performance at temperatures that would cause materials like PTFE or POM to fail. PEEK can operate reliably in continuous service up to 260°C (500°F) and can handle excursions up to 315°C (600°F).

While PEEK offers the highest temperature resistance for a soft-seated valve, the truly "best" material is always a function of three critical variables: temperature, pressure, and chemical compatibility. Understanding their interplay is essential for ensuring valve integrity and system safety.

Why PEEK Excels in Demanding Environments

PEEK is a high-performance semi-crystalline thermoplastic engineered for the most challenging industrial applications. Its advantages go beyond simple heat tolerance.

Unmatched Thermal Stability

PEEK's maximum continuous service temperature is approximately 260°C, with a short-term ceiling of 315°C. This makes it suitable for many high-pressure steam services and hot process fluid applications where other polymers would degrade.

Superior Mechanical Strength

Unlike some materials that soften significantly as temperatures rise, PEEK retains a high degree of rigidity and creep resistance. This prevents the seat from deforming or extruding under high pressure and temperature, which is a common failure mode for lesser materials.

Broad Chemical Resistance

In addition to its thermal properties, PEEK offers excellent resistance to a wide range of organic and inorganic chemicals and is highly resistant to hydrolysis in hot water or steam.

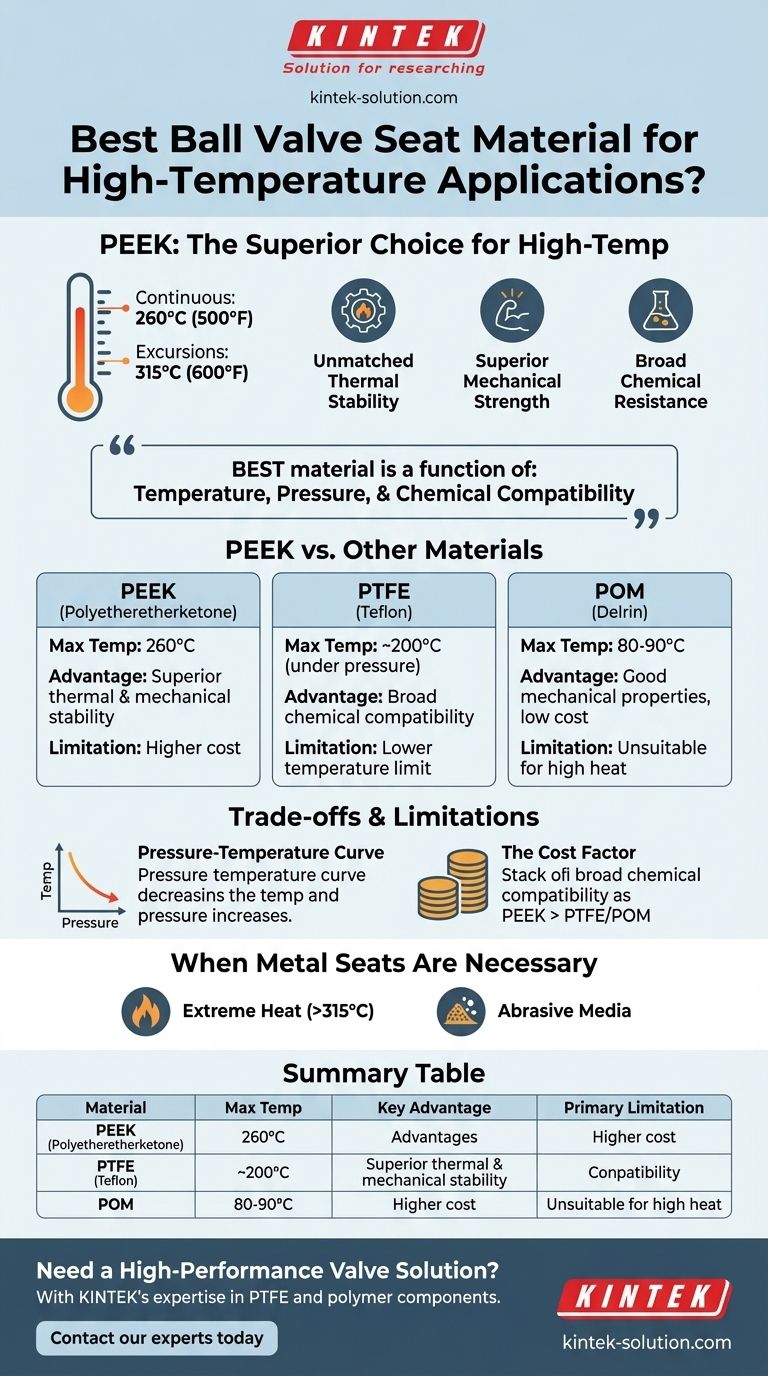

Comparing PEEK to Other Seat Materials

To understand PEEK's value, it's helpful to compare it against other widely used valve seat materials.

The Role of PTFE (Teflon)

PTFE is prized for its nearly universal chemical compatibility and low-friction surface. However, its temperature limit is significantly lower than PEEK's, typically maxing out around 260°C but often de-rated to well below 200°C under pressure.

The Limitations of POM (Delrin)

POM is a strong, general-purpose plastic used in low-pressure, ambient-temperature applications. It provides good mechanical properties but is not suitable for high temperatures, with a typical maximum service temperature of only around 80-90°C.

Understanding the Trade-offs and Limitations

No material choice is without compromise. Acknowledging the limitations of PEEK is critical for proper specification.

The Cost Factor

PEEK is a premium engineering polymer, and its cost reflects that. Valves with PEEK seats are significantly more expensive than those with standard PTFE or POM seats. This cost must be justified by the demands of the service.

The Pressure-Temperature Curve

A material's maximum temperature rating is not an absolute. It is always dependent on the system pressure. As operating pressure increases, the maximum allowable temperature for any seat material, including PEEK, will decrease. Always consult the valve manufacturer's pressure-temperature chart.

When Metal Seats Are Necessary

Even PEEK has its limits. For applications exceeding 315°C or those involving abrasive media like slurries or catalysts, a soft seat is not appropriate. In these cases, you must specify a metal-seated ball valve, which creates a seal through direct metal-to-metal contact, often enhanced with hard coatings.

Making the Right Choice for Your Application

Selecting the correct seat material requires a clear understanding of your primary operational goal.

- If your primary focus is high heat and steam service (up to ~260°C): PEEK is the definitive choice among soft seats for its unmatched combination of thermal and mechanical stability.

- If your primary focus is broad chemical compatibility at moderate temperatures (below 180°C): PTFE often provides the most cost-effective and reliable performance.

- If you are operating above 315°C or in highly abrasive conditions: You must move beyond soft seats and specify a valve with metal seats.

Ultimately, choosing the right material based on a complete analysis of your service conditions is the foundation of a safe and reliable system.

Summary Table:

| Material | Max Continuous Temp | Key Advantage | Primary Limitation |

|---|---|---|---|

| PEEK | 260°C (500°F) | Superior thermal & mechanical stability | Higher cost |

| PTFE | ~200°C (under pressure) | Broad chemical compatibility | Lower temperature limit |

| POM | 80-90°C | Good mechanical properties at low cost | Unsuitable for high heat |

| Metal Seats | >315°C | Necessary for extreme heat/abrasion | No soft seal, higher torque |

Need a High-Performance Valve Solution for Demanding Conditions?

Selecting the right valve seat material is critical for system safety and longevity. At KINTEK, we specialize in manufacturing high-precision PTFE and advanced polymer components, including seals and liners, for the most challenging environments in the semiconductor, medical, laboratory, and industrial sectors.

We can help you navigate the trade-offs between temperature, pressure, and chemical compatibility to specify the perfect component. Whether you need a custom prototype or high-volume production of reliable PTFE parts, our expertise ensures optimal performance.

Let's engineer a solution for your specific application. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Evaporating Dishes for Diverse Applications

People Also Ask

- What are PTFE bellows and diaphragms, and why are they important in critical systems?

- How does PTFE benefit the semiconductor industry? Essential for High-Purity Chip Fabrication

- What are the key features of PTFE diaphragms? Maximize Performance in Demanding Applications

- What are the common applications of PTFE diaphragms in the Chinese market? Key Uses in Chemical, Pharma & Semiconductor

- How does the low coefficient of friction of PTFE balls benefit their use in valves and pumps? Enhance Efficiency and Reliability