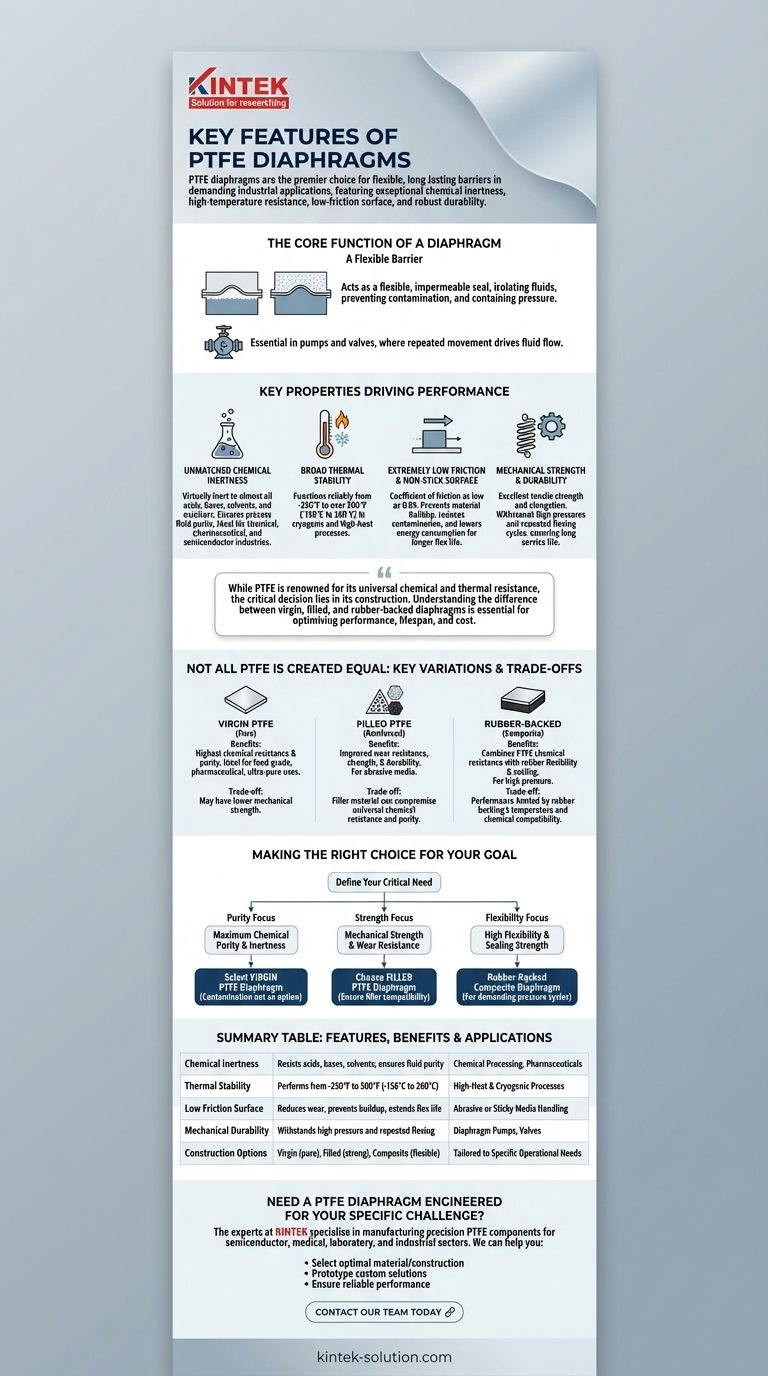

The key features of a PTFE diaphragm are its exceptional chemical inertness, high-temperature resistance, low-friction surface, and robust durability. These properties make it a premier choice for creating a flexible, long-lasting barrier in demanding industrial applications involving aggressive fluids, high pressures, and extreme temperatures.

While PTFE is renowned for its universal chemical and thermal resistance, the critical decision lies in its construction. Understanding the difference between virgin, filled, and rubber-backed diaphragms is essential for optimizing performance, lifespan, and cost in your specific application.

The Core Function of a Diaphragm

A Flexible Barrier

A diaphragm's primary role is to act as a flexible, impermeable seal between two chambers. It isolates fluids, prevents contamination, and contains pressure while being able to move and flex.

Essential in Pumps and Valves

This function is critical in equipment like diaphragm pumps and valves, where the diaphragm's repeated movement drives fluid flow or controls a process line.

Key Properties Driving Performance

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, solvents, and oxidizers. This property prevents material degradation and ensures the purity of the process fluid.

This makes PTFE diaphragms the default choice for applications in the chemical processing, pharmaceutical, and semiconductor industries where material compatibility is non-negotiable.

Broad Thermal Stability

PTFE maintains its integrity and performance across an exceptionally wide temperature range, typically from -250°F to over 500°F (-156°C to 260°C). This allows it to function reliably in both cryogenic and high-heat processes where other materials would fail.

Extremely Low Friction and Non-Stick Surface

With a coefficient of friction as low as 0.05, PTFE has one of the slickest surfaces known. This non-adhesive quality prevents material buildup, reduces the risk of contamination, and lowers the energy required for the diaphragm to flex.

This characteristic directly contributes to a longer flex life and more consistent performance over time, as the diaphragm experiences less surface wear and resistance.

Mechanical Strength and Durability

High-quality PTFE diaphragms possess excellent tensile strength and elongation properties, allowing them to withstand high pressures and repeated flexing cycles without failing. This mechanical robustness ensures a long service life and reduces equipment downtime.

Not All PTFE is Created Equal: Key Variations

The term "PTFE diaphragm" can refer to several distinct constructions, each engineered for different operational demands.

Virgin PTFE

This is pure, unfilled polytetrafluoroethylene. It offers the highest level of chemical resistance and purity, making it ideal for food-grade, pharmaceutical, or ultra-pure semiconductor applications where any contamination is unacceptable.

Filled PTFE

In this construction, materials like glass fiber, carbon, or graphite are added to the PTFE matrix. These fillers significantly improve mechanical properties such as wear resistance, strength, and durability.

Filled PTFE is often used in applications with abrasive media or where a longer mechanical lifespan is the top priority.

Rubber-Backed (Composite) Diaphragms

These diaphragms bond a thin layer of PTFE to a more robust, flexible rubber backing, such as EPDM or Viton. This design combines the universal chemical resistance of the PTFE "wetted side" with the strength and resilience of the rubber.

This construction is common in high-pressure applications that require superior sealing and flexibility.

Understanding the Trade-offs

Choosing the right diaphragm requires acknowledging the limitations of each type.

Filled PTFE: A Compromise on Purity

While filled PTFE offers superior mechanical strength, the filler material can compromise its universal chemical resistance. You must ensure the filler itself is compatible with your process fluid to avoid unexpected degradation. This also makes it unsuitable for applications demanding the highest purity.

Composite Diaphragms: The Weakest Link

In a rubber-backed diaphragm, the overall performance is limited by the properties of the rubber. The operating temperature range and chemical compatibility will be dictated by the backing material (e.g., EPDM), not the PTFE layer.

Making the Right Choice for Your Goal

To select the correct diaphragm, first define your most critical operational need.

- If your primary focus is maximum chemical purity and inertness: Select a virgin PTFE diaphragm for applications where contamination is not an option.

- If your primary focus is mechanical strength and wear resistance: Choose a filled PTFE diaphragm, ensuring the filler material is compatible with your process.

- If your primary focus is high flexibility and sealing strength: A rubber-backed composite diaphragm provides the necessary resilience for demanding pressure cycles.

By looking beyond the material and focusing on the construction, you ensure the diaphragm you select is precisely engineered for its task.

Summary Table:

| Feature | Benefit | Key Application |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents; ensures fluid purity | Chemical Processing, Pharmaceuticals |

| Thermal Stability | Performs from -250°F to 500°F (-156°C to 260°C) | High-Heat & Cryogenic Processes |

| Low Friction Surface | Reduces wear, prevents buildup, extends flex life | Abrasive or Sticky Media Handling |

| Mechanical Durability | Withstands high pressure and repeated flexing | Diaphragm Pumps, Valves |

| Construction Options | Virgin (pure), Filled (strong), Composite (flexible) | Tailored to Specific Operational Needs |

Need a PTFE Diaphragm Engineered for Your Specific Challenge?

Choosing the right PTFE diaphragm construction—whether virgin, filled, or composite—is critical to the performance, longevity, and cost-effectiveness of your equipment. The experts at KINTEK specialize in manufacturing precision PTFE components, including custom diaphragms, for the semiconductor, medical, laboratory, and industrial sectors.

We can help you:

- Select the optimal material and construction for your chemical, temperature, and pressure requirements.

- Prototype and fabricate custom solutions tailored to your exact specifications.

- Ensure reliable performance and reduce downtime with components built for durability.

Let's engineer a solution for you. Contact our team today to discuss your application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What types of contaminants should be avoided with PTFE-lined bearings? Protect Your Investment and Maximize Performance

- What are the main advantages of PTFE washers in industrial applications? Unlock Superior Chemical & Thermal Performance

- What methods are used to apply PTFE coatings to fasteners? Dip vs. Spray Coating Explained

- Why is selecting the right PTFE packing important? Ensure Reliable Sealing & Prevent Costly Failures

- What are the advantages of PTFE envelope pipe gaskets? Superior Sealing for Harsh Chemical & Pure Processes

- What are the primary applications of PTFE-lined ball valves? Control Corrosive & High-Purity Fluids

- What factors should be considered when choosing between spiral and split PTFE backup rings?

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained