In the Chinese market, the most common applications for PTFE diaphragms are found in demanding industrial sectors such as chemical processing, pharmaceutical manufacturing, and semiconductor fabrication. Their adoption is driven by an essential need for materials that can withstand aggressive chemicals, high temperatures, and stringent purity requirements without failing.

The core reason for PTFE's dominance in these critical applications is its unique combination of near-universal chemical inertness and exceptional thermal stability, making it the default choice for creating reliable, non-contaminating barriers in harsh operational environments.

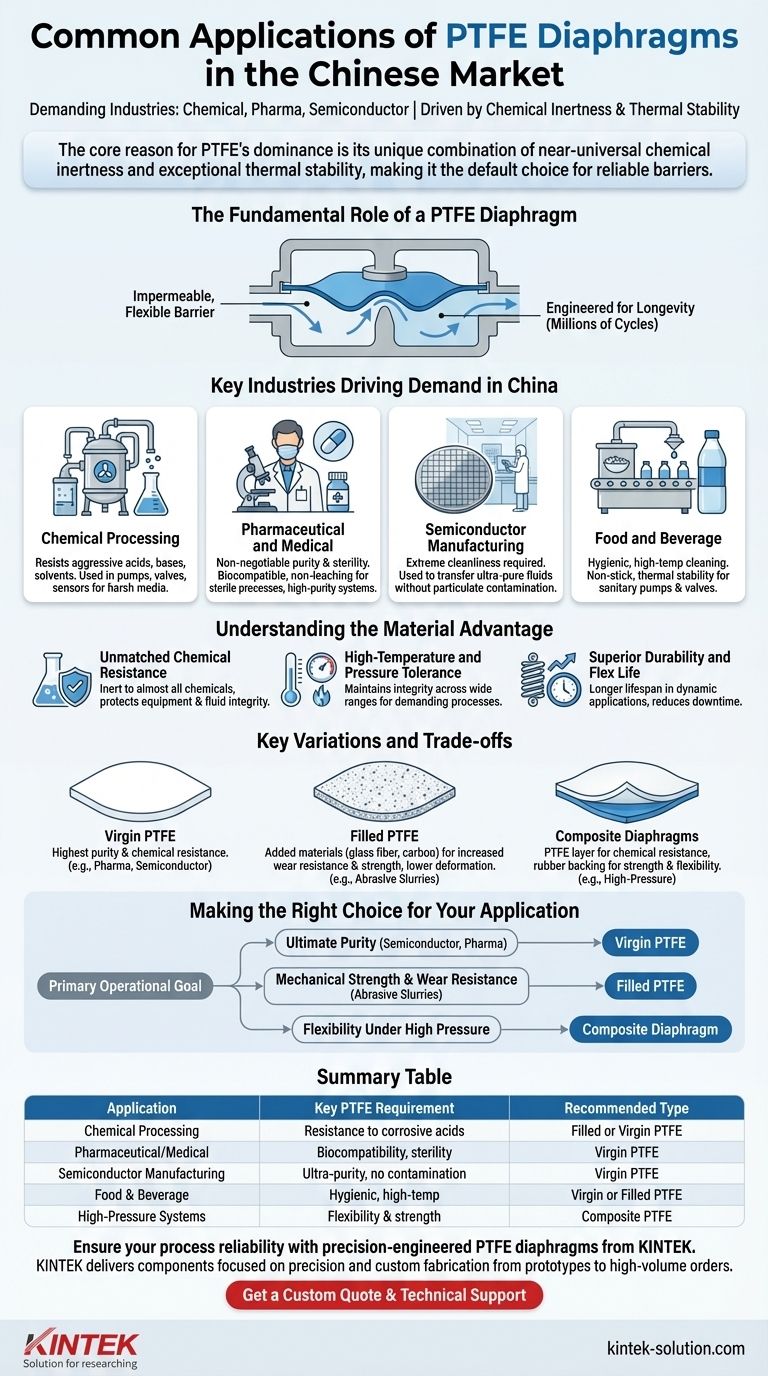

The Fundamental Role of a PTFE Diaphragm

A diaphragm acts as a flexible, impermeable seal that separates two chambers. Its function is to isolate or transfer media—often fluids or gases—while preventing leaks or cross-contamination.

An Impermeable, Flexible Barrier

The primary job of a PTFE diaphragm is to serve as a robust barrier. It flexes under pressure to pump fluids or actuate valves without allowing the process media to escape or contaminants to enter.

Engineered for Longevity

These components are designed for a long flex life. They must endure millions of cycles of pressurization and movement without cracking, degrading, or losing their sealing capability, making material choice critical.

Key Industries Driving Demand in China

The rapid industrial growth in China has created significant demand for high-performance components. PTFE diaphragms are central to operations in several key sectors.

Chemical Processing

In the chemical industry, diaphragms are constantly exposed to highly corrosive acids, bases, and solvents. PTFE's ability to resist nearly all industrial chemicals makes it essential for pumps, valves, and sensors handling aggressive media.

Pharmaceutical and Medical

Purity and sterility are non-negotiable in pharmaceutical and medical applications. PTFE is biocompatible and does not leach contaminants, ensuring it is safe for use in sterile processes, diagnostic equipment, and fluid handling systems for high-purity ingredients.

Semiconductor Manufacturing

The semiconductor fabrication process requires extreme cleanliness and the use of aggressive chemicals. PTFE diaphragms are used in pumps and valves to transfer these ultra-pure fluids without introducing particulate contamination that could ruin microchips.

Food and Beverage

For food and beverage production, equipment must be hygienic and withstand high temperatures for cleaning and sterilization. PTFE's non-stick properties and thermal stability make it an ideal material for diaphragms in sanitary pumps and valves.

Understanding the Material Advantage

PTFE is not simply one option among many; for certain applications, its properties make it the only viable choice. Understanding these advantages explains its widespread use.

Unmatched Chemical Resistance

PTFE is inert to almost every chemical, a property that protects the integrity of both the equipment and the process fluid. This prevents diaphragm degradation and product contamination.

High-Temperature and Pressure Tolerance

This material maintains its structural integrity and performance characteristics across a wide range of temperatures and pressures, enabling its use in demanding industrial processes.

Superior Durability and Flex Life

Compared to many other materials, PTFE offers a longer operational lifespan, especially in dynamic applications involving constant flexing. This reduces downtime and maintenance costs.

Key Variations and Trade-offs

Not all PTFE diaphragms are the same. The choice of type depends entirely on the specific demands of the application.

Virgin PTFE

This is pure, unfilled PTFE. It is specified for applications where the highest degree of purity and chemical resistance is paramount, such as in the semiconductor and pharmaceutical industries.

Filled PTFE

In this type, materials like glass fiber, carbon, or graphite are added to the PTFE. This enhancement significantly increases wear resistance, reduces deformation under load, and improves mechanical strength, but it may compromise the material's absolute chemical purity.

Composite Diaphragms

These diaphragms combine a layer of PTFE with a more flexible rubber backing (like EPDM or FKM). The PTFE layer provides the chemical resistance, while the rubber backing adds strength and flexibility, making it ideal for high-pressure applications.

Making the Right Choice for Your Application

Selecting the correct diaphragm is critical for ensuring process safety, reliability, and efficiency. Your decision should be guided by your primary operational goal.

- If your primary focus is ultimate purity (semiconductor, pharma): Virgin PTFE is the required standard to prevent any form of process contamination.

- If your primary focus is mechanical strength and wear resistance (abrasive chemical slurries): A filled PTFE compound offers the enhanced durability needed for a longer service life.

- If your primary focus is flexibility under high pressure: A composite diaphragm with a suitable rubber backing provides the optimal balance of chemical resistance and robust mechanical performance.

By matching the material's properties to the application's demands, you can ensure your system operates with maximum reliability and efficiency.

Summary Table:

| Application | Key PTFE Diaphragm Requirement | Recommended Type |

|---|---|---|

| Chemical Processing | Resistance to corrosive acids, solvents | Filled or Virgin PTFE |

| Pharmaceutical/Medical | Biocompatibility, sterility, no leaching | Virgin PTFE |

| Semiconductor Manufacturing | Ultra-purity, no particulate contamination | Virgin PTFE |

| Food & Beverage | Hygienic, withstands sterilization | Virgin or Filled PTFE |

| High-Pressure Systems | Flexibility and strength under pressure | Composite PTFE |

Ensure your process reliability with precision-engineered PTFE diaphragms from KINTEK.

Whether your priority is ultimate purity for semiconductor manufacturing, chemical resistance for harsh processing environments, or custom mechanical properties for specialized equipment, KINTEK delivers. We manufacture high-performance PTFE components—including seals, liners, and labware—with a focus on precision and custom fabrication from prototypes to high-volume orders.

Contact us today to discuss your specific requirements and let our expertise enhance your system's efficiency and longevity.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency