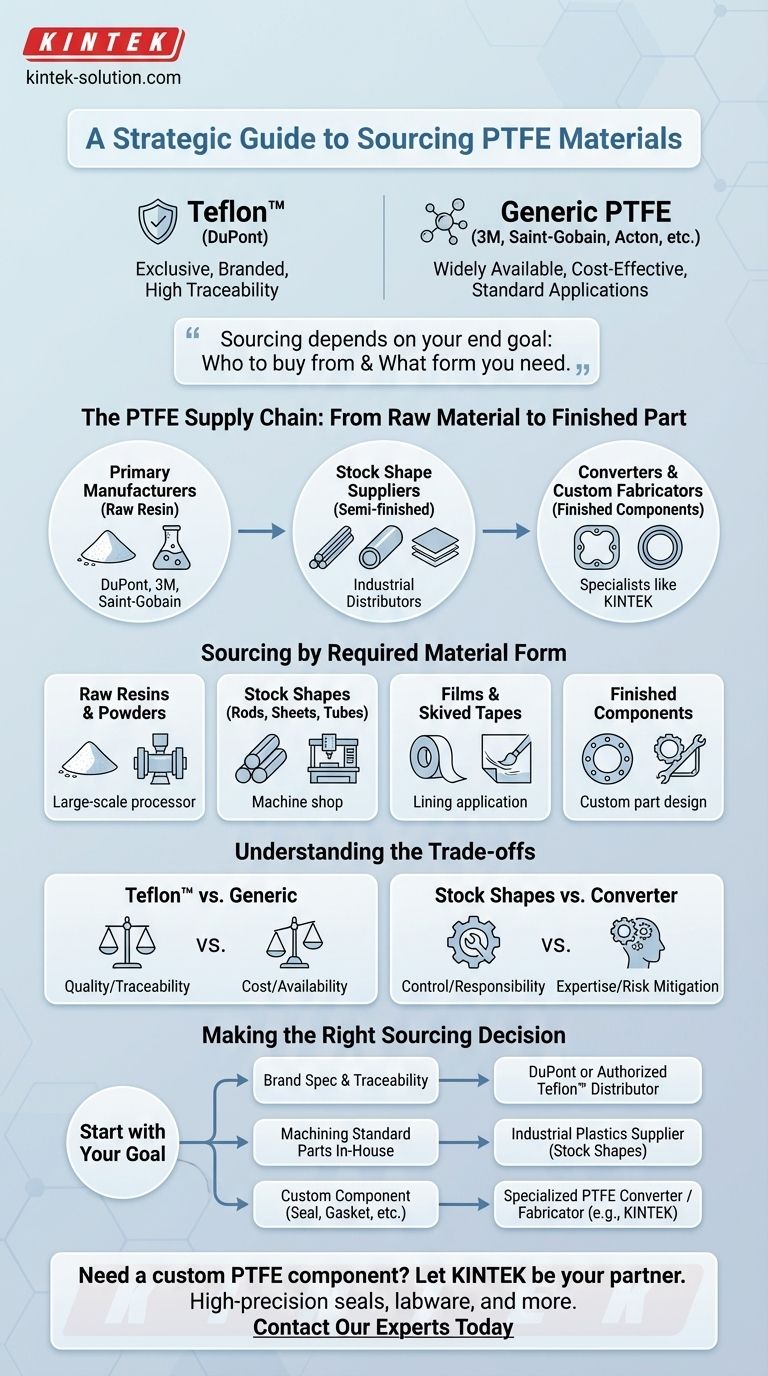

To source PTFE, you must first distinguish between the brand name Teflon™, which is exclusively available from DuPont and its authorized distributors, and generic PTFE. Generic PTFE materials can be procured from a range of major chemical and plastics suppliers, including 3M, Saint-Gobain Performance Plastics, and Acton Technologies.

Your sourcing strategy for PTFE depends entirely on your end goal. The central decision is not just who to buy from, but what form you need—raw material, a standard shape for machining, or a finished component fabricated by a specialist.

The PTFE Supply Chain: From Raw Material to Finished Part

Understanding the players in the supply chain is critical to sourcing PTFE efficiently. You rarely buy the raw chemical polymer directly; instead, you work with a partner who processes it into a usable form.

The Role of Primary Manufacturers

Primary manufacturers are the large chemical companies that polymerize tetrafluoroethylene (TFE) into PTFE resin.

They produce the base material, often in the form of granular powders or fine dispersions. Companies like DuPont (for Teflon™), 3M, and Saint-Gobain operate at this level. Most end-users do not purchase directly from them.

Stock Shape Suppliers and Distributors

These companies purchase raw PTFE resin from manufacturers and convert it into standardized, semi-finished products.

This is the most common sourcing point for machine shops and engineering firms. The material is provided in forms ready for fabrication, including extruded tubes and rods, molded sheets, and skived tapes.

Converters and Custom Fabricators

For specific applications like gaskets or seals, partnering with a converter is the most effective approach.

A converter is a specialist that integrates material selection with part design and production. They purchase stock shapes and use their expertise to create a finished component that meets precise engineering requirements.

Sourcing by Required Material Form

The form in which you buy PTFE dictates your supplier. You must identify what you need before you can identify who to contact.

Raw Resins and Powders

This is the most basic form of PTFE, used for large-scale compression molding or paste extrusion. It is typically only purchased by other large-scale processors and stock shape suppliers.

Stock Shapes (Rods, Sheets, Tubes)

These are the standard, semi-finished products used for machining custom parts. If you have in-house CNC machining capabilities, you will likely source PTFE in this form from a major industrial plastics distributor.

Films and Skived Tapes

PTFE can be "skived" from a large billet into a very thin film or tape. These materials are used for linings, insulation, and specialized non-stick surface applications.

Finished Components

If your goal is a final part, such as a custom-designed gasket, your best source is a fabricator or converter. They handle the entire process from sourcing the appropriate grade of PTFE stock to manufacturing the final part.

Understanding the Trade-offs

Making the right sourcing decision involves balancing cost, quality control, and the level of expertise you need from your supplier.

Brand Name (Teflon™) vs. Generic PTFE

Choosing the DuPont Teflon™ brand often ensures a high degree of quality control, traceability, and access to specialized formulations. Generic PTFE from other reputable manufacturers can be more cost-effective and is suitable for many standard applications where brand-specific properties are not required.

Sourcing Stock Shapes vs. Working with a Converter

Purchasing stock shapes gives you full control over the machining and fabrication process. However, this places the responsibility for material selection and design viability entirely on you.

Partnering with a converter offloads this risk. They provide invaluable expertise, ensuring that the chosen PTFE grade and the part's design are perfectly matched for the application, which is especially critical for complex parts like high-performance gaskets.

Making the Right Sourcing Decision

Your sourcing strategy should align directly with your project's technical and logistical needs.

- If your primary focus is brand specification and traceability: Source Teflon™-branded materials directly from DuPont or its authorized distributors.

- If your primary focus is machining standard parts in-house: Procure generic PTFE stock shapes like rods and sheets from major industrial plastic suppliers.

- If your primary focus is creating a custom-designed component like a seal or gasket: Engage a specialized PTFE converter to guide material selection and manage the fabrication process.

Choosing the right supplier is the first critical step in ensuring your component's performance and reliability.

Summary Table:

| Sourcing Goal | Recommended Supplier Type | Key Considerations |

|---|---|---|

| Brand Specification & Traceability | DuPont or Authorized Teflon™ Distributor | Ensures high quality, specialized formulations |

| Machining Standard Parts In-House | Industrial Plastics Supplier (Stock Shapes) | Provides rods, sheets, tubes for custom fabrication |

| Custom Components (Seals, Gaskets, etc.) | Specialized PTFE Converter/Fabricator | Offers material selection expertise and full production |

Need a custom PTFE component? Let KINTEK be your sourcing and fabrication partner. We specialize in manufacturing high-precision PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. From prototype to high-volume production, we ensure your component is perfectly matched to your application. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications