In short, Teflon encapsulated silicone o-rings are used in demanding industrial applications where a seal requires both the chemical inertness of Teflon and the flexible, compressive properties of silicone. They are go-to components in aggressive environments like chemical processing, pharmaceutical manufacturing, aerospace, and semiconductor production where standard elastomer seals would quickly fail.

The core value of a Teflon encapsulated o-ring is its ability to deliver the best of both worlds: the extreme chemical resistance of a Teflon (PTFE) surface combined with the reliable, elastic sealing capability of a silicone core.

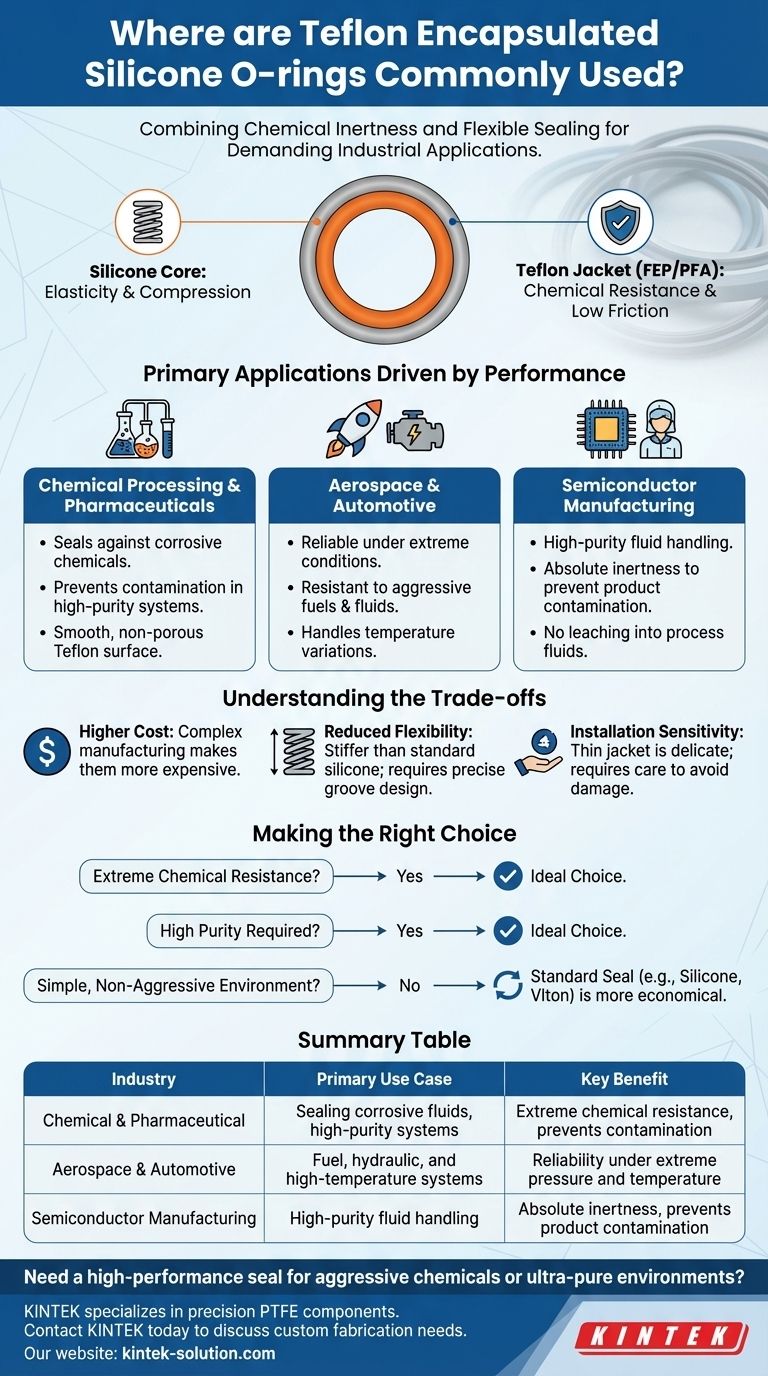

The Engineering Principle: A Hybrid Design for Harsh Conditions

To understand where these o-rings are used, you must first understand why they were created. They solve a fundamental material conflict between chemical resistance and sealing flexibility.

The Silicone Core: The Source of Elasticity

The inner core of the o-ring is made from silicone. This material provides the excellent compression and memory needed to create and maintain a tight seal over a wide temperature range.

Without this elastic core, a solid Teflon o-ring would be too rigid and prone to leaking under pressure and temperature fluctuations.

The Teflon Jacket: The Shield Against Aggression

A seamless layer of Teflon (FEP or PFA) completely encloses the silicone core. This outer jacket is the part that comes into contact with the sealed media.

Teflon is one of the most chemically inert materials known, providing a barrier against corrosive chemicals, solvents, and aggressive fluids. It also offers extremely low friction, which reduces wear in dynamic applications.

Primary Applications Driven by Performance

The unique hybrid design makes these o-rings essential in industries where seal failure is not an option.

Chemical Processing & Pharmaceuticals

In these sectors, seals are constantly exposed to a wide range of corrosive chemicals. The Teflon jacket prevents chemical attack on the o-ring, ensuring seal integrity.

Furthermore, the smooth, non-porous surface of Teflon prevents contamination, making it ideal for the high-purity systems common in pharmaceutical manufacturing.

Aerospace & Automotive

Reliability under extreme conditions is paramount. These o-rings are used in systems requiring high-performance seals that can tolerate aggressive fuels, hydraulic fluids, and significant temperature variations.

The combination of the Teflon jacket and silicone core ensures a consistent seal despite the demanding operational environment.

Semiconductor Manufacturing

The manufacturing of semiconductors involves high-purity fluid handling systems where even microscopic contamination can ruin entire batches of product.

The inertness of the Teflon jacket ensures that nothing leaches from the o-ring into the process fluids, maintaining the absolute purity required.

Understanding the Trade-offs

While highly effective, these specialized o-rings are not a universal solution. Understanding their limitations is key to using them correctly.

Higher Cost

The complex manufacturing process of encapsulating a core within a seamless jacket makes these o-rings significantly more expensive than standard single-material o-rings like Viton or silicone.

Reduced Flexibility

The Teflon jacket is less elastic than the silicone core. This makes the overall o-ring stiffer than a standard silicone o-ring, which can require more precise groove design and higher compression force to ensure a perfect seal.

Installation Sensitivity

The thin Teflon jacket is the key to the o-ring's performance. Care must be taken during installation to avoid scratching or damaging this layer, as any breach would expose the vulnerable silicone core to chemical attack.

Making the Right Choice for Your Application

Choosing the correct seal requires matching the component's properties to the system's demands.

- If your primary focus is extreme chemical resistance: This is the ideal choice, especially when sealing aggressive media that would degrade standard elastomers.

- If your system requires high purity: The inert Teflon surface is perfect for pharmaceutical, food and beverage, or semiconductor applications where preventing contamination is critical.

- If you need a simple seal in a non-aggressive environment: A standard, lower-cost silicone, EPDM, or Viton o-ring is likely a more economical and effective solution.

By combining two distinct materials, the Teflon encapsulated o-ring provides a high-performance sealing solution for the most challenging environments.

Summary Table:

| Industry | Primary Use Case | Key Benefit |

|---|---|---|

| Chemical & Pharmaceutical | Sealing corrosive fluids, high-purity systems | Extreme chemical resistance, prevents contamination |

| Aerospace & Automotive | Fuel, hydraulic, and high-temperature systems | Reliability under extreme pressure and temperature |

| Semiconductor Manufacturing | High-purity fluid handling | Absolute inertness, prevents product contamination |

Need a high-performance seal for aggressive chemicals or ultra-pure environments?

KINTEK specializes in manufacturing precision PTFE components, including custom Teflon encapsulated o-rings. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering the exact chemical resistance and sealing reliability your application demands.

Contact KINTEK today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability