In short, PTFE lined butterfly valves are most beneficial in applications that handle highly corrosive media or require exceptional purity. Their value shines in industries like chemical processing, pharmaceuticals, water treatment, and petrochemicals, where a standard valve would quickly fail or contaminate the process.

The core purpose of a PTFE lined butterfly valve is not general-purpose flow control, but rather to provide a chemically inert and non-contaminating barrier in demanding environments. Its primary benefit comes from the protective properties of the PTFE lining itself.

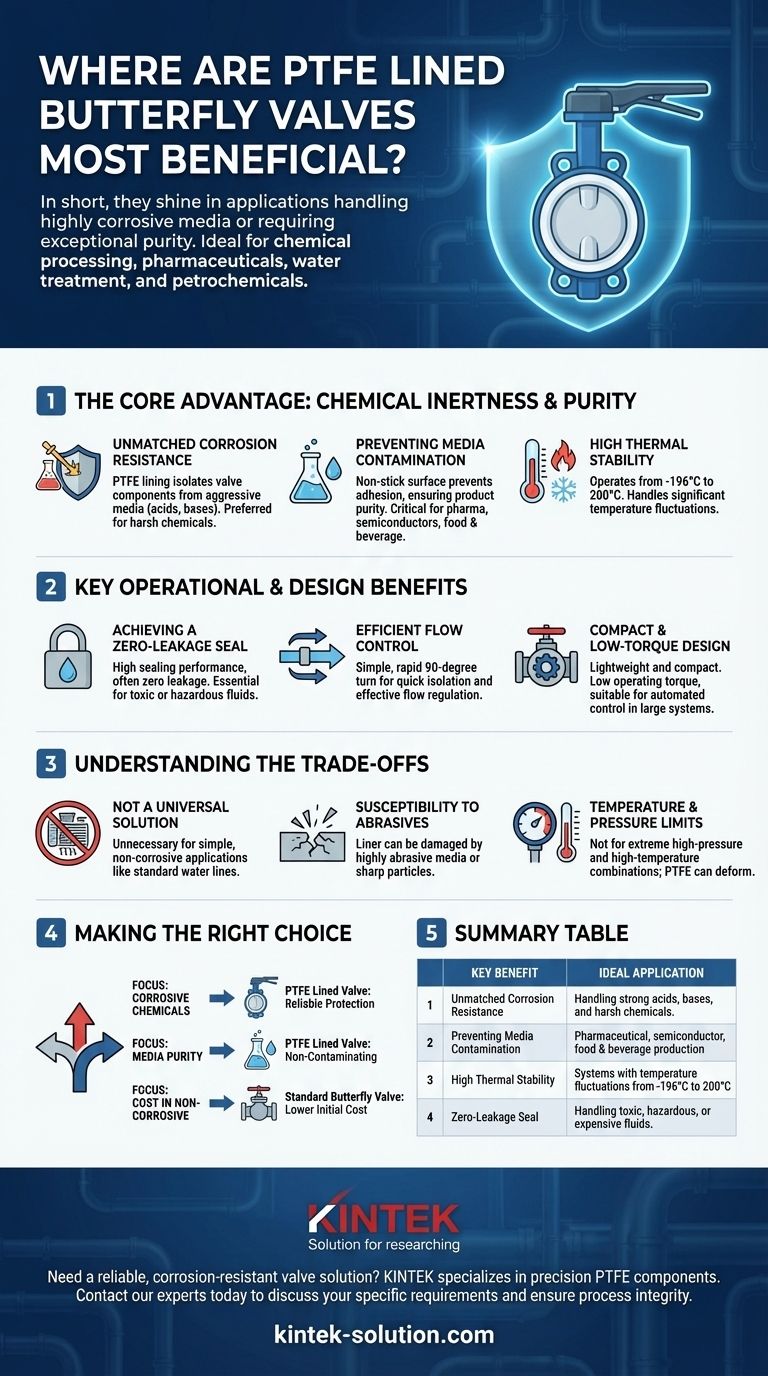

The Core Advantage: Chemical Inertness and Purity

The decision to use a PTFE lined butterfly valve is driven by the need to protect the valve's core components from the media flowing through it, or to protect the media from the valve.

Unmatched Corrosion Resistance

The standout feature of these valves is their superior resistance to corrosion. The PTFE (Polytetrafluoroethylene) lining isolates the valve body and stem from aggressive media.

This makes them the preferred choice for handling strong acids, bases, and other harsh chemicals found in chemical processing, petroleum refining, and environmental protection sectors.

Preventing Media Contamination

PTFE is an incredibly pure and non-stick material. This property is critical in industries where even microscopic contamination can ruin a batch.

In pharmaceutical, semiconductor, and food and beverage production, the smooth, inert surface prevents media from adhering to the valve, ensuring product purity and preventing buildup.

High Thermal Stability

These valves are effective across a wide operational temperature range, typically from -196°C to 200°C (-320°F to 392°F).

This versatility allows them to be deployed in systems that experience significant temperature fluctuations without compromising performance or material integrity.

Key Operational and Design Benefits

Beyond their chemical properties, the design of these valves offers distinct operational advantages that make them suitable for modern industrial plants.

Achieving a Zero-Leakage Seal

PTFE lined butterfly valves are engineered for high sealing performance, often achieving zero leakage.

This is critical when handling toxic, hazardous, or expensive fluids where any escape could pose a safety risk or result in significant financial loss.

Efficient Flow Control

Like other butterfly valves, they offer a simple and rapid operating principle. A 90-degree turn of the stem moves the disc from fully closed to fully open.

This allows for quick isolation and effective regulation of flow within a system.

Compact and Low-Torque Design

The inherent design of a butterfly valve is compact and lightweight compared to other valve types like gate or globe valves.

Their low operating torque makes them particularly well-suited for actuated or automated control, especially in large-diameter piping systems where manual operation would be impractical.

Understanding the Trade-offs

While highly effective in their intended role, PTFE lined valves are a specialized tool. Understanding their limitations is key to using them correctly.

Not a Universal Solution

For simple, non-corrosive applications like standard water lines or HVAC systems, a PTFE lined valve is often unnecessary and not cost-effective. A standard resilient-seated or high-performance butterfly valve is the more practical choice.

Susceptibility to Abrasives

While suitable for some slurries, the PTFE liner can be susceptible to damage from highly abrasive media. Sharp particles can score or tear the lining, compromising its protective barrier.

Temperature and Pressure Limits

While the temperature range is broad, it is not limitless. In applications with extreme high-pressure and high-temperature combinations, an all-metal valve may be required as PTFE can deform under such stress. They are most cost-effective in normal to moderate temperature and pressure ranges.

Making the Right Choice for Your Application

Selecting the correct valve hinges entirely on the specific demands of your system and the media it will handle.

- If your primary focus is handling corrosive or aggressive chemicals: The inert PTFE lining provides the essential protection that makes these valves the default, reliable choice.

- If your primary focus is maintaining media purity: The non-stick, non-contaminating surface of PTFE is indispensable for applications in pharmaceuticals, food processing, and semiconductors.

- If your primary focus is cost-efficiency in a non-corrosive system: A standard, unlined butterfly valve will provide the necessary flow control at a lower initial cost.

Ultimately, choosing a PTFE lined butterfly valve is a strategic decision to ensure system longevity and integrity in chemically aggressive or high-purity environments.

Summary Table:

| Key Benefit | Ideal Application |

|---|---|

| Unmatched Corrosion Resistance | Handling strong acids, bases, and harsh chemicals in chemical processing and petrochemicals. |

| Preventing Media Contamination | Pharmaceutical, semiconductor, and food & beverage production requiring high purity. |

| High Thermal Stability | Systems with temperature fluctuations from -196°C to 200°C. |

| Zero-Leakage Seal | Handling toxic, hazardous, or expensive fluids where safety is critical. |

Need a reliable, corrosion-resistant valve solution for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom-fabricated seals, liners, and labware. Our expertise ensures your systems in the semiconductor, medical, laboratory, and industrial sectors are protected against aggressive media and contamination.

Contact our experts today to discuss your specific requirements—from prototypes to high-volume orders—and ensure the integrity of your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support