Machining is the preferred fabrication method for PTFE when your project demands high precision, involves complex geometries, or is for prototyping and low-volume production runs. This subtractive process allows for intricate designs and tight tolerances that are often impractical or uneconomical to achieve with other methods like molding for smaller quantities.

While PTFE's softness makes it easy to cut, achieving true precision is a challenge reserved for skilled machinists. The core trade-off is between the design flexibility of machining and the cost-effectiveness of molding for high-volume production.

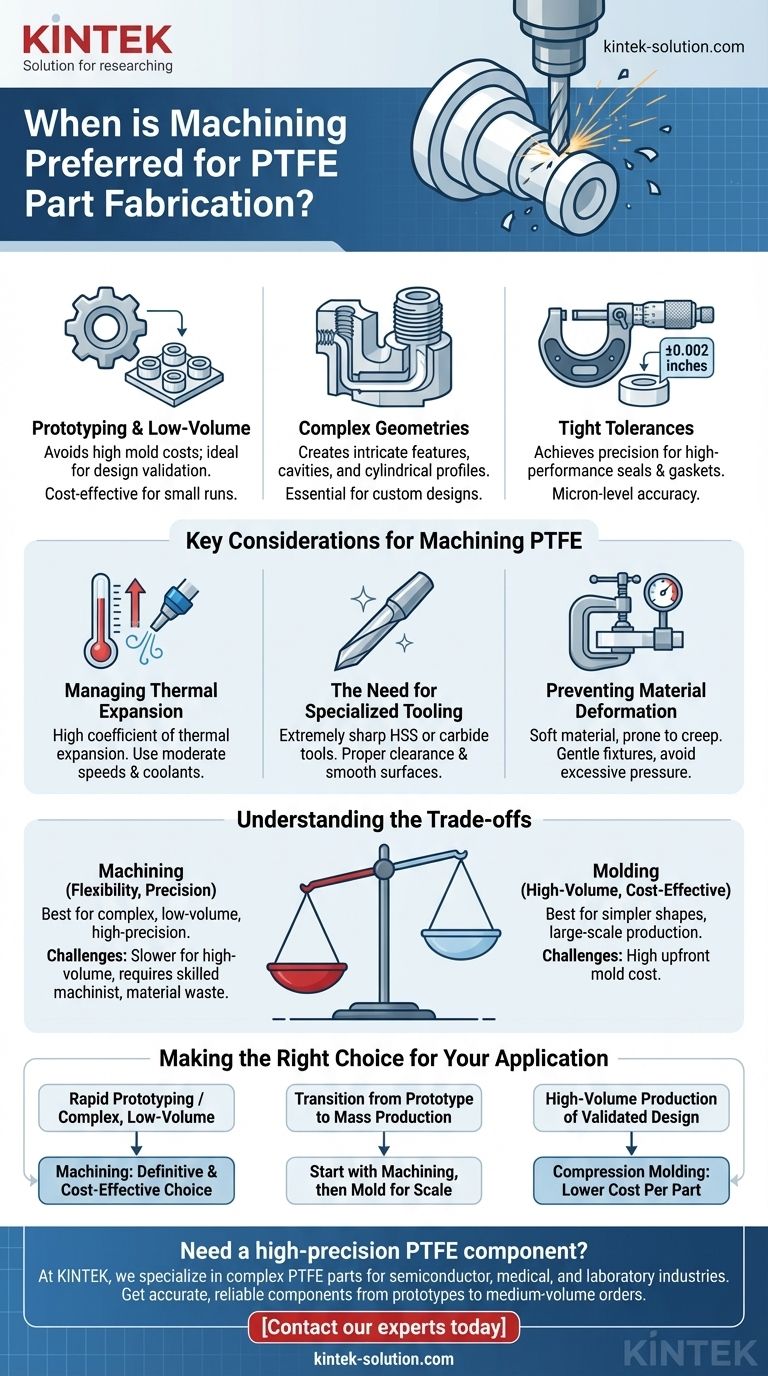

Why Choose Machining for PTFE?

Machining offers distinct advantages for specific applications by leveraging modern tooling to work around PTFE's unique material properties. It is the go-to method when the part's final form and dimensional accuracy are paramount.

Achieving Tight Tolerances

CNC machining equipment can produce PTFE components with micron-level accuracy. This precision is critical for high-performance parts like seals, gaskets, and insulators.

Despite challenges from thermal expansion and stress creep, experienced machinists can consistently hold tolerances within ±0.002 inches, ensuring dimensional stability and reliable performance.

Fabricating Complex Geometries

Methods like CNC milling and CNC turning enable the creation of intricate features, cavities, and cylindrical profiles. This is essential for custom components that cannot be formed using a simple mold.

If your design includes complex curves, threaded holes, or unique surface patterns, machining is the most direct and reliable fabrication path.

Prototyping and Low-Volume Production

Machining is exceptionally cost-effective for small quantities. It avoids the significant upfront investment in designing and creating custom molds, which is only justifiable for large-scale production.

This makes it the ideal choice for creating functional prototypes to validate a design before committing to mass production tooling.

Key Considerations for Machining PTFE

Successfully machining PTFE requires a deep understanding of its material science. Its properties are fundamentally different from metals, and standard techniques must be adapted to prevent defects and ensure accuracy.

Managing Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. Heat generated during cutting can quickly ruin a part's dimensions.

To mitigate this, machinists use moderate cutting speeds (200-500 surface feet per minute), high feed rates, and sometimes liquid coolants to dissipate heat effectively.

The Need for Specialized Tooling

Standard cutting tools can tear or deform the soft material. Success requires extremely sharp and polished cutting tools, often made from high-speed steel (HSS) or carbide.

Proper tool clearance and smooth surfaces are critical to ensure a clean cut and prevent material from sticking to the tool.

Preventing Material Deformation

PTFE is soft and prone to stress creep, meaning it can slowly deform under constant pressure. Fixtures and clamps must be used with care to hold the workpiece securely without crushing it.

Avoiding excessive cutting pressure and tool vibration is essential for achieving a smooth, accurate surface finish.

Understanding the Trade-offs

While powerful, machining is not the universal solution for all PTFE parts. Understanding its limitations is key to making a sound engineering and business decision.

The Challenge of High-Volume Production

For large production runs of thousands or millions of parts, machining is significantly slower and more expensive per part than compression molding.

Molding offers lower per-unit costs and faster cycle times once the initial tooling investment is made, making it the superior choice for mass production of simpler shapes.

The Myth of "Easy" Machining

The statement that PTFE is "easy to machine" refers only to its softness and the ease of material removal. Achieving precision and repeatability is a highly skilled task.

The combination of thermal expansion, softness, and creep makes it one of the more challenging polymers to machine to tight tolerances.

Material Waste

Machining is a subtractive process, meaning it creates the final shape by cutting away material from a larger stock piece (like a rod or sheet). This generates waste, known as swarf.

For an expensive material like PTFE, this waste can be a notable cost factor, especially when compared to a near-net-shape process like molding.

Making the Right Choice for Your Application

Selecting the correct fabrication method comes down to balancing precision, complexity, production volume, and cost.

- If your primary focus is rapid prototyping or complex, low-volume parts: Machining is the definitive and most cost-effective choice.

- If your primary focus is high-volume production of a validated, simpler design: Compression molding will provide a significantly lower cost per part.

- If your goal is to transition from prototype to mass production: Start with machined parts to perfect the design, then invest in molding tools for scalable manufacturing.

By understanding these core principles, you can confidently select the fabrication method that best leverages PTFE's unique advantages for your specific engineering challenge.

Summary Table:

| Scenario | Why Machining is Preferred |

|---|---|

| Prototyping & Low-Volume | Avoids high mold costs; ideal for design validation. |

| Complex Geometries | Creates intricate features, threads, and cavities. |

| Tight Tolerances | Achieves precision within ±0.002 inches for critical parts. |

| High-Volume Production | Not Preferred; molding is more cost-effective. |

Need a high-precision PTFE component?

At KINTEK, we specialize in machining complex PTFE parts for the semiconductor, medical, and laboratory industries. Our expertise in managing PTFE's unique properties ensures you get accurate, reliable seals, liners, and labware—from prototypes to medium-volume orders.

Contact our experts today to discuss your custom fabrication needs and get a precise quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments