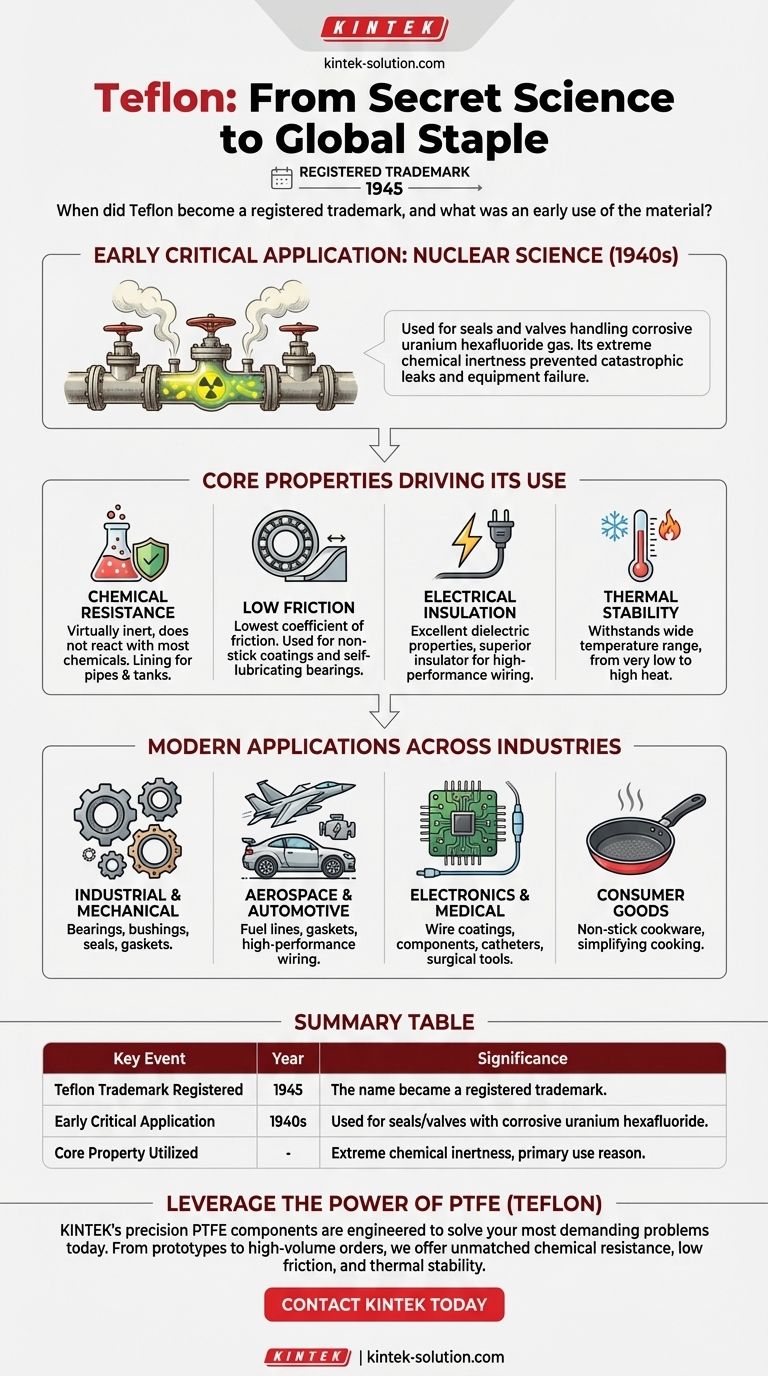

Teflon was registered as a trademark in 1945, and one of its earliest and most critical applications was not in the kitchen, but in nuclear science. Before it became a household name for non-stick pans, its unique properties were essential for handling highly corrosive materials during the development of atomic energy.

While famous for non-stick cookware, Teflon's true value stems from its extreme chemical inertness and remarkably low friction. These properties made it an indispensable material for mission-critical industrial and scientific applications decades before its consumer debut.

From Secret Project to Global Staple

The story of Teflon's application begins in a high-stakes, secretive environment where no other material could do the job. This origin explains why it became so ubiquitous across countless industries.

An Early Use in Uranium Enrichment

One of Teflon's first major uses was coating valves and seals within the pipes of a massive uranium enrichment plant. The process required handling highly corrosive uranium hexafluoride gas, a substance that would destroy most conventional materials.

Teflon's near-total chemical inertness was the solution, preventing catastrophic leaks and equipment failure in this critical environment.

The Core Properties Driving Its Use

Teflon’s value is rooted in a unique combination of characteristics. Understanding these properties is key to understanding its versatility.

- Chemical Resistance: It is virtually inert and does not react with most chemicals, making it perfect for lining pipes, tanks, and containers for aggressive substances.

- Low Friction: It has one of the lowest coefficients of friction of any solid, which is why it's used for non-stick coatings and self-lubricating bearings and seals.

- Electrical Insulation: It has excellent dielectric properties, meaning it does not conduct electricity, making it a superior insulator for high-performance wiring and electrical components.

- Thermal Stability: It can withstand a wide range of temperatures, from very low to high heat, without degrading.

Modern Applications Across Industries

The same properties that made Teflon essential for nuclear science have led to its adoption in nearly every modern sector. Its use as a coating or a solid component solves persistent engineering challenges.

In Industrial and Mechanical Systems

In machinery, Teflon is used for bearings, bushings, seals, and gaskets. Its low-friction nature reduces wear and tear on moving parts, often eliminating the need for liquid lubricants.

In Aerospace and Automotive

The aerospace and automotive industries rely on Teflon for high-performance applications. It is used in fuel lines, gaskets, and wire insulation where resistance to heat and chemicals is paramount.

In Electronics and Medical Devices

As a superb electrical insulator, Teflon is used to coat wiring and manufacture components for demanding electronic applications.

In the medical field, its inertness and slipperiness make it ideal for catheters, surgical tools, and medical device coatings that must not react with the human body.

In Consumer Goods

The most famous application is in non-stick cookware. A thin layer of Teflon on pans, skillets, and baking sheets prevents food from sticking, simplifying both cooking and cleaning.

How to Apply This to Your Project

The decision to use a material like Teflon is always driven by the primary problem you need to solve. Its unique properties make it the ideal choice for specific, challenging conditions.

- If your primary focus is extreme chemical resistance: Teflon is the standard for lining pipes and vessels or for creating seals that will be exposed to corrosive materials.

- If your primary focus is minimizing friction: It is the go-to solution for non-stick surfaces or for bearings and mechanical parts that must operate smoothly with low wear.

- If your primary focus is high-temperature electrical insulation: Its stability and dielectric properties make it a top choice for wiring in demanding aerospace, automotive, or industrial environments.

Ultimately, Teflon's journey from a secret industrial material to a kitchen staple demonstrates how solving a single, critical problem can unlock a world of applications.

Summary Table:

| Key Event | Year | Significance |

|---|---|---|

| Teflon Trademark Registered | 1945 | The name "Teflon" became a registered trademark. |

| Early Critical Application | 1940s | Used for seals and valves handling corrosive uranium hexafluoride gas in nuclear projects. |

| Core Property Utilized | - | Extreme chemical inertness, which remains a primary reason for its use today. |

Leverage the Power of PTFE (Teflon) for Your Critical Applications

Just as Teflon's unique properties solved critical challenges in the 1940s, KINTEK's precision PTFE components are engineered to solve your most demanding problems today. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated seals, liners, and labware offer unmatched chemical resistance, low friction, and thermal stability.

We specialize in transforming this versatile material into reliable solutions, from prototypes to high-volume orders.

Contact KINTEB today to discuss how our PTFE expertise can enhance your project's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications