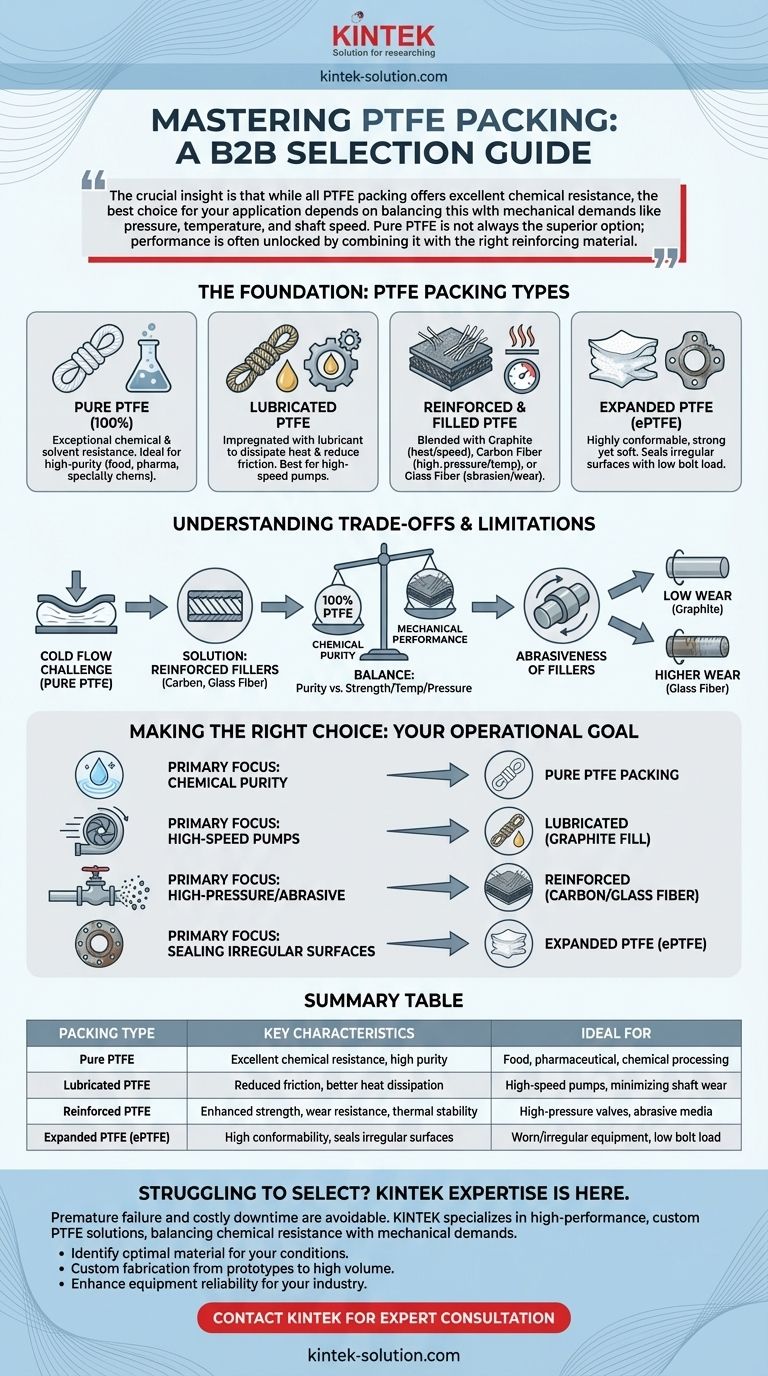

The primary types of PTFE packing are differentiated by their construction and the materials they are blended with. The main categories include pure (100%) PTFE packing, lubricated PTFE packing, and various forms of reinforced or filled PTFE packing, such as those blended with graphite or carbon fiber to enhance specific mechanical properties.

The crucial insight is that while all PTFE packing offers excellent chemical resistance, the best choice for your application depends on balancing this with mechanical demands like pressure, temperature, and shaft speed. Pure PTFE is not always the superior option; performance is often unlocked by combining it with the right reinforcing material.

The Foundation: Understanding PTFE Packing Construction

Polytetrafluoroethylene (PTFE) is a highly versatile polymer, but its raw properties are modified in packing materials to suit specific industrial environments. The construction of the packing dictates its ideal use case.

Pure PTFE Packing (100%)

This type, often called PTFE gland packing, is made from pure PTFE yarns braided into a flexible, rope-like form.

Its primary advantage is its exceptional resistance to nearly all industrial chemicals and solvents. It is the go-to choice where product purity is paramount, such as in food processing, pharmaceutical, and specialty chemical applications.

Lubricated PTFE Packing

This packing consists of PTFE yarns that have been impregnated with a break-in or high-temperature lubricant.

The lubricant helps dissipate heat, reduce friction during initial startup, and improve sealing in high-speed applications. This makes it a common choice for pumps where minimizing shaft wear and managing heat are critical concerns.

Reinforced & Filled PTFE Packing

To overcome some of the mechanical limitations of pure PTFE, manufacturers create composite packings by blending PTFE with other materials. These fillers dramatically improve strength, wear resistance, and thermal conductivity.

- PTFE with Graphite: This is one of the most common and effective combinations. Graphite is an excellent conductor of heat and a natural lubricant. Adding it to PTFE packing allows it to handle higher shaft speeds and temperatures by drawing heat away from the equipment.

- PTFE with Carbon Fiber: For high-pressure and high-temperature applications, carbon fiber reinforcement is used. It significantly increases the packing's mechanical strength, dimensional stability, and resistance to extrusion under heavy loads, making it ideal for demanding valve services.

- PTFE with Glass Fiber: Incorporating glass fibers enhances the packing's wear resistance and rigidity. This type is well-suited for applications involving abrasive media or where maintaining a stable seal under pressure is essential.

Expanded PTFE (ePTFE)

Expanded PTFE is a unique material created by rapidly stretching PTFE under specific conditions, resulting in a strong yet soft and highly conformable structure.

As a packing or gasketing material, ePTFE is excellent for sealing worn or irregularly shaped equipment surfaces. It provides a tight, long-lasting seal with very little bolt load and maintains the outstanding chemical resistance of pure PTFE.

Understanding the Trade-offs

Selecting the right packing requires acknowledging the inherent compromises between different material compositions. Making the wrong choice can lead to premature failure and equipment damage.

The "Cold Flow" Challenge of Pure PTFE

Pure PTFE has a tendency to "cold flow," meaning it can slowly deform or creep out of place when subjected to constant pressure and temperature. This is its primary mechanical weakness.

Fillers like carbon and glass fiber are added specifically to counteract this tendency, providing a more stable and reliable long-term seal in high-pressure environments.

Balancing Purity vs. Performance

The most chemically resistant packing is 100% pure PTFE. However, it is also the mechanically weakest.

In contrast, a carbon-fiber-reinforced packing is incredibly strong but may not be suitable for applications like food processing where absolute purity is required. You must always weigh the need for chemical inertness against the demands of pressure, temperature, and abrasion.

Abrasiveness of Fillers

While fillers enhance mechanical properties, some can be more abrasive to equipment shafts than others. For instance, glass-fiber-filled packing is extremely durable but may cause more shaft wear over time compared to a graphite-filled variant.

This trade-off is critical when selecting packing for high-speed rotating equipment where preserving the shaft surface is a priority.

Making the Right Choice for Your Application

Your operational goal is the single most important factor in determining the correct PTFE packing.

- If your primary focus is chemical purity and corrosion resistance: Choose 100% pure PTFE gland packing for its unmatched inertness in aggressive media.

- If your primary focus is high-speed pumps and heat dissipation: Select a lubricated packing with graphite fill to manage friction and prevent overheating.

- If your primary focus is high-pressure valves or abrasive media: Use a reinforced packing with carbon or glass fibers for maximum mechanical strength and wear resistance.

- If your primary focus is sealing older or irregular equipment surfaces: Consider conformable Expanded PTFE (ePTFE) packing to create a reliable seal with minimal force.

Understanding these fundamental distinctions empowers you to select a sealing solution that ensures both optimal performance and long-term equipment reliability.

Summary Table:

| Packing Type | Key Characteristics | Ideal For |

|---|---|---|

| Pure PTFE | Excellent chemical resistance, high purity | Food, pharmaceutical, chemical processing |

| Lubricated PTFE | Reduced friction, better heat dissipation | High-speed pumps, minimizing shaft wear |

| Reinforced PTFE | Enhanced strength, wear resistance, thermal stability | High-pressure valves, abrasive media |

| Expanded PTFE (ePTFE) | High conformability, seals irregular surfaces | Worn or irregular equipment, low bolt load applications |

Struggling to Select the Right PTFE Packing?

Choosing the wrong packing can lead to premature failure, equipment damage, and costly downtime. The ideal seal balances chemical resistance with the mechanical demands of your specific application—whether it's high pressure, temperature, speed, or a need for absolute purity.

KINTEK specializes in manufacturing high-performance PTFE components, including custom packing solutions. We understand the critical trade-offs between materials like pure PTFE, graphite-filled, and carbon-fiber-reinforced variants. Our team can help you:

- Identify the optimal material for your operating conditions (chemicals, pressure, temperature, shaft speed).

- Provide custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and performance.

- Enhance equipment reliability and longevity with seals designed for your industry's challenges.

Targeting the semiconductor, medical, laboratory, and industrial sectors, we prioritize precision and durability. Don't leave your sealing performance to chance.

Contact KINTEK today for a expert consultation and let us engineer a solution that ensures peak performance and reliability for your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications